From a long time, one of the main types of wall decoration is the plaster. When plastering walls are planned, the consumption of materials determines the choice of finishing type.

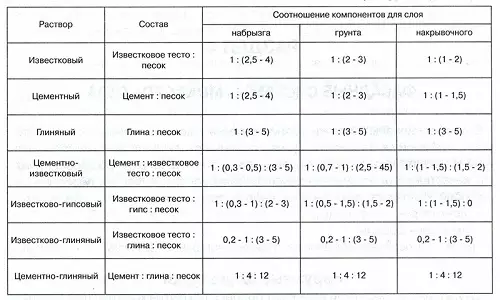

Calculation of the number of plaster solutions.

For plastering walls, a wide range of solutions is used and proposed. Numerous dry building mixtures are manufactured on a different basis and are ready to satisfy any requirement. The plaster solution can be prepared with your own hands, and it will not give way to the quality of the purchase mixture. All this suggests that when shuttering is conceived, the consumption of materials should be carried out correctly and reliably.

Material features

The plaster is a finishing layer, preparing the wall to the finishing coating. From what plastering is made, the consumption of materials differs noticeably. For the purpose, three types of plaster are distinguished:

- Chernovaya - for leveling local irregularities.

- Basic - to align the verticality of the whole wall.

- Final or putty - to smooth the surface to final coating.

Classification of plaster.

Each type of finishing is superimposed as a layer of different thickness and different solution, both in composition and consistency.

From what the wall is made, the type of plaster and consumption of materials depends. So, on top of the chipboard or drywall, only two layers are usually superimposed - rough and final. Brick requires the mandatory overlay of all three layers. Concrete is usually placed in three layers, but a two-layer plaster can be used. The type of plaster depends on the location of the wall, i.e. from external affecting factors. Outdoor and internal walls are isolated, as well as internal walls exposed to moisture and pair (bathroom, sauna).

Finally, the consumption of materials and the thickness of the main layer of plaster significantly affects the curvature of the surface, its defectiveness and the degree of deviation from the vertical. Wall covering chipboard or drywall significantly reduces the consumption of materials, as the verticality of the wall and the smoothness of the main part of the surface is ensured (with the exception of seams). Thus, when plaster works are performed, the consumption of materials depends on the design of the wall, the type of plaster and the degree of curvature or the defectiveness of the surface.

Article on the topic: 3 Apartments in Bohemian Style: Phototour and Interior Review (20 photos)

Features of plaster makeup

Consumption of plaster on 1m2.

Plaster can be made with a ready-made mixture or homemade solution. Of the homemade compositions, you can allocate basic views. The cement-sandy solution is made in the form of a mixture of cement and sand in proportions 1: (2-6). In the final layer, the amount of sand may increase. Cement for work is used mainly by the M400 brand for external coatings and M200 for internal work. The cement-lime-sandy solution is prepared from the cement mixture, hazed lime and sand in proportions 1: 1: (3-5). Lime and sand are mixed together with obtaining a limestone test, after which they mix with cement.

The lime-gypsum solution consists of a mixture of gypsum with a limestone test in proportion 1: (3-4). In turn, the limestone dough is a mixed haired lime and sand in a 1: 3 ratio. A lime-clay solution contains a mixture of clay with sand and with hawed lime in a ratio of 1: 0.4: (3-6). The limestone is a mixture of hawed lime with sand in proportion 1: (3-5).

Cement-sand solutions are of great popularity. On the content of cement, the solutions are divided into skinny (ratio of 1: 5 and more sand); fat (ratio of 1: 2) and normal at a ratio of 1: (3-4). The most durable solutions belong to fatty species, but they can crack. In addition, they have an increased cement consumption, which leads to the rise in the cost of the composition. The least susceptible to cracking the skinny types, which causes their use in the final layer. By density, the solutions are divided into a heavy type (more than 1500 kg / m³) and a light type (less than 1500 kg / m³). The greatest application for internal works finds a more plastic cement-lime-sandy solution.

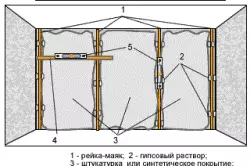

The scheme of performing high-quality plaster walls on the racks.

In order to make a solution more plastic and elastic, various additives are used, for example, detergents (economic soap, shampoo, etc.). To increase the time of pouring the solution and increasing elasticity, PVA and joinery glue is added. Such additives usually do not exceed 2-5% by weight.

Article on the topic: How to paint the lining on the balcony: choose varnish, impregnation, paint

Recently, ready-made dry mixes are actively used. The most common compositions include dry plastering options based on cement for external and internal works, as well as finishing putty mixtures on the same basis. For interior decoration, a dry plaster and putty mixture is suitable on a plaster basis. Special and fairly effective compositions include dry decorative plaster, a mixture of "Coroed" for exterior walls, Venetian plaster, a mixture "Optimist", the finish coating of "VOLMA" and a number of others.

Calculation of consumption of materials

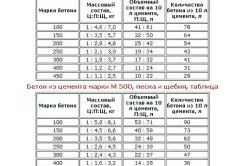

The first estimated calculation of the consumption of materials on the plaster wall is carried out without taking into account a number of factors, just on the area of the coating. For example, the wall has an area of 20 m². The thickness of the main layer is 5 cm, i.e. 0.05 m. Elementary calculation shows that the volume of plaster is 1 m³ or, in terms of water volume, 1000 liters. A mixture of cement with sand in a 1: 3 ratio by volume is used. Consequently, the consumption of cement on the plaster of the walls will be 1: 4 = 0.25 m², and the flow of sand is 0.75 m³. At the density of cement 1600 kg / m³, the weight consumption of cement for work will be 400 kg. If a cement-lime-sandy solution is used in a ratio of 1: 1: 4, similar calculations show that cement consumption will be 0.17 m³, or 272 kg.Accounting for some factors

Wall plaster diagram.

In practice, the wall has a certain curvature. Accurate accounting of this factor requires numerous measurements and calculations, which does not make much sense. Approximate accounting of the curvature of the wall can be introduced into the calculation of the average thickness of the actual layer. For this, the minimum and maximum thickness of the plaster layer is determined, and is the average value of this value. For example, the minimum thickness was 14 mm, and the maximum thickness is 32 mm. Consequently, the average value will be (44 + 52) / 2 = 48 mm. Taking into account this value, recalculation of previous calculations.

In the preliminary calculation, the area of the wall was taken as the area of the correct rectangle, i.e. As a product of the length on the height of the surface. In actual calculations, it is necessary to take into account the deviation of the height of the wall and parallelism. The calculation of the middle height of the wall and its average length is taken. Measures are made at three points - in the center and at the edges. The value is averaged in three values. In addition, the deviation of the angles from 90 ° is taken into account. Reaching the area due to this defect is simply subtracted from the calculated value.

Article on the topic: how to make doors - with threshold or without

The more accurate calculation of the draft layer is difficult to measure the dimensions of the defects. The calculation should take the size of the largest defects. For example, when taking into account the draft layer according to the chipboard, the coating is calculated approximately the seam volume between the sheets, as a product of the seam length on the width and the thickness of the chipboard sheet.

Most often, the accuracy of calculations is not needed.

Preliminary estimated calculation gives a slightly overestimated consumption of materials, which can be useful when carrying out other construction work.

This arises due to the fact that the thickness of the main layer of plaster is normalized to the maximum size.

Consumption of standard mixes

When using purchased ready-made mixtures, it is necessary to focus on the recommendation on the consumption of material indicated on the package. For example, some characteristic costs of finished mixtures with recommended plaster thicknesses should be brought. Gypsum plastering mixture When applied to a wall of 10 mm thick chipboard will have a recommended consumption of 9 kg / m². Cement consumption in the mixture will be an average of 16-18 kg / m². Decorative plaster will require about 8 kg / m³. From other types of plaster solutions, one can mark the following consumption per 1 m²:- "Old" - 1.5 kg;

- "Rotbend" - 8.5 kg (with a layer thickness of 5 cm);

- "Coroed" - up to 3 kg;

- Venetian plaster - 0.2 kg.

Necessary materials

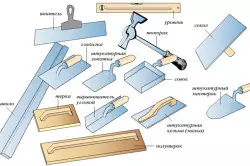

Tools required for plaster.

When plastering walls, the following materials are commonly used:

- Cement M200 and M400;

- Sand-sized sand with grains of the middle fraction (preferably, river quartz);

- Lime hawed or limestone dough;

- construction plaster;

- clay (alumina);

- purified water;

- carpentry glue;

- PVA glue;

- Dry plaster mix for internal and external work.

When plaster works are manufactured, it is necessary to plan the consumption of materials in advance so that there is no need to compensate for the shortage. An unexpected stop in the work may affect the quality of plaster.