Recent years, in the construction of the house or repair, much attention is paid to energy efficiency. With already existing fuel prices, this is very relevant. Moreover, it seems that the savings will continue to acquire increasing importance. In order to correctly select the composition and thickness of materials in the cake of the enclosing structures (walls, floor, ceiling, roofing) you need to know the thermal conductivity of building materials. This characteristic is indicated on packages with materials, and it is still necessary at the design stage. After all, it is necessary to solve what material to build walls than to warm them, which thickness should be each layer.

What is thermal conductivity and thermal resistance

When choosing building materials for construction, it is necessary to pay attention to the characteristics of materials. One of the key positions is thermal conductivity. It is displayed by the thermal conductivity coefficient. This is the amount of heat that can conduct one or another material per unit of time. That is, the smaller this coefficient, the worse the material carries out heat. And vice versa, the higher the figure, the heat is given better.

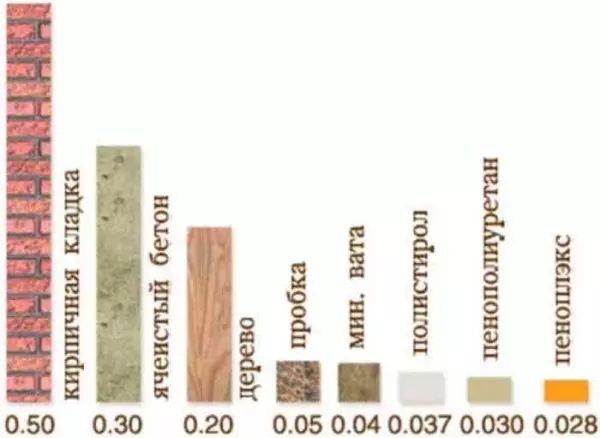

A diagram that illustrates the difference in the thermal conductivity of materials

Materials with low thermal conductivity are used for insulation, with high - to transfer or remove heat. For example, radiators are made of aluminum, copper or steel, as they are well transmitted heat, that is, they have a high thermal conductivity coefficient. For insulation, materials with a low thermal conductivity coefficient are used - they are better preserved heat. In case the object consists of several layers of material, its thermal conductivity is defined as the sum of the coefficients of all materials. When calculating, the thermal conductivity of each of the "cake" components is calculated, the values found are summed up. In general, we obtain the thermal insulation capacity of the enclosing structure (walls, gender, ceiling).

The thermal conductivity of building materials shows the amount of heat that he misses per unit of time.

There is also such a concept as thermal resistance. It displays the ability of the material to prevent the passage along it. That is, it is a reverse value in relation to thermal conductivity. And if you see a material with high thermal resistance, it can be used for thermal insulation. An example of thermal insulation materials may be a popular mineral or basalt wool, foam, etc. Materials with low thermal resistance are needed for the lead or heat transfer. For example, aluminum or steel radiators are used for heating, as they are well given warmly.

Table of thermal conductivity of thermal insulation materials

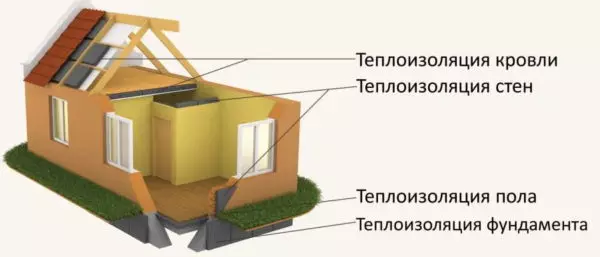

In order for the house to be easier to maintain heat in winter and coolness in summer, the thermal conductivity of the walls, the floor and the roof should be an equally defined figure that is calculated for each region. The composition of the "cake" of walls, gender and ceiling, the thickness of the materials are taken with such an accounting so that the total number is no less (and better - at least a little more) recommended for your region.

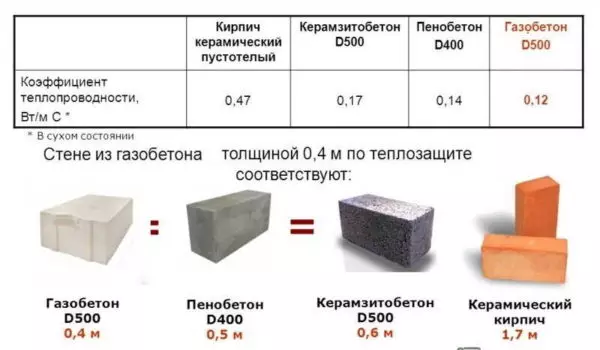

Coefficient of heat transfer of materials of modern building materials for enclosing structures

When choosing materials it is necessary to consider that some of them (not all) in conditions of high humidity are carried out much better. If there is such a situation during operation for a long time, in the calculations, thermal conductivity is used for this state. The thermal conductivity coefficients of the main materials that are used for insulation are shown in the table.

| Name of material | Coefficient of thermal conductivity W / (M · ° C) | ||

|---|---|---|---|

| In dry condition | With normal humidity | With high humidity | |

| Felt woolen | 0.036-0.041 | 0.038-0.044 | 0.044-0.050 |

| Stone mineral wool 25-50 kg / m3 | 0.036 | 0.042. | 0 , 045 |

| Stone mineral wool 40-60 kg / m3 | 0.035 | 0.041 | 0.044. |

| Stone mineral wool 80-125 kg / m3 | 0.036 | 0.042. | 0.045 |

| Stone mineral wool 140-175 kg / m3 | 0.037 | 0,043. | 0,0456. |

| Stone mineral wool 180 kg / m3 | 0.038 | 0.045 | 0,048. |

| Glasswater 15 kg / m3 | 0,046. | 0.049. | 0.055 |

| Glasswater 17 kg / m3 | 0.044. | 0.047. | 0,053 |

| Glasswater 20 kg / m3 | 0.04. | 0,043. | 0,048. |

| Glasswater 30 kg / m3 | 0.04. | 0.042. | 0,046. |

| Glasswater 35 kg / m3 | 0.039 | 0.041 | 0,046. |

| Glasswater 45 kg / m3 | 0.039 | 0.041 | 0.045 |

| Glasswater 60 kg / m3 | 0.038 | 0,040. | 0.045 |

| Glasswater 75 kg / m3 | 0.04. | 0.042. | 0.047. |

| Glasswater 85 kg / m3 | 0.044. | 0,046. | 0,050 |

| Polystyrene foam (foam, PPS) | 0.036-0.041 | 0.038-0.044 | 0.044-0.050 |

| Extruded expanded polystyrene foam (EPPS, XPS) | 0,029 | 0.030 | 0.031 |

| Foam concrete, aerated concrete solution, 600 kg / m3 | 0.14. | 0.22. | 0.26. |

| Foam concrete, aerated concrete at cement mortar, 400 kg / m3 | 0.11 | 0.14. | 0.15 |

| Foam concrete, aerated concrete on a lime solution, 600 kg / m3 | 0.15 | 0.28. | 0.34. |

| Foam concrete, aerated concrete on a lime solution, 400 kg / m3 | 0.13. | 0.22. | 0.28. |

| Foam glass, crumb, 100 - 150 kg / m3 | 0.043-0.06 | ||

| Foam glass, crumb, 151 - 200 kg / m3 | 0.06-0.063 | ||

| Foamwalk, baby, 201 - 250 kg / m3 | 0.066-0.073 | ||

| Foam glass, crumb, 251 - 400 kg / m3 | 0.085-0.1 | ||

| Foam block 100 - 120 kg / m3 | 0.043-0.045 | ||

| Foam block 121-170 kg / m3 | 0.05-0.062. | ||

| Foam block 171 - 220 kg / m3 | 0.057-0.063 | ||

| Foam block 221 - 270 kg / m3 | 0.073 | ||

| Ekwata. | 0.037-0.042 | ||

| Polyurethane Foolder (PPU) 40 kg / m3 | 0,029 | 0.031 | 0.05 |

| Polyurethane foam (PPU) 60 kg / m3 | 0.035 | 0.036 | 0.041 |

| Polyurethane Foolder (PPU) 80 kg / m3 | 0.041 | 0.042. | 0.04. |

| Polyeneetylene stitched | 0.031-0.038 | ||

| Vacuum | |||

| Air + 27 ° C. 1 atm | 0,026. | ||

| Xenon | 0.0057 | ||

| Argon | 0.0177 | ||

| Aergel (Aspen Aerogels) | 0,014-0.021 | ||

| Shagkovat | 0.05 | ||

| Vermikulitis | 0.064-0.074 | ||

| Foamed rubber | 0.033 | ||

| Cork sheets 220 kg / m3 | 0.035 | ||

| Cork sheets 260 kg / m3 | 0.05 | ||

| Basalt mats, canvas | 0.03-0.04 | ||

| Tow | 0.05 | ||

| Perlite, 200 kg / m3 | 0.05 | ||

| Perlite Running, 100 kg / m3 | 0.06. | ||

| Plates of linen insulating, 250 kg / m3 | 0.054 | ||

| Polystyrevbeton, 150-500 kg / m3 | 0.052-0.145 | ||

| Granulated tube, 45 kg / m3 | 0.038 | ||

| Mineral plug on a bitumen basis, 270-350 kg / m3 | 0.076-0.096 | ||

| Floor cork coating, 540 kg / m3 | 0,078. | ||

| Technical cork, 50 kg / m3 | 0.037 |

Article on the topic: Swan cross stitch patterns: Swan Couple for free, black loyalty to the pond, girl and sets, prin

Part of the information is taken by standards that prescribe the characteristics of certain materials (SNiP 23-02-2003, SP 50.13330.2019, SNIP II-3-79 * (Appendix 2)). Those material that are not spelled out in standards are found on manufacturers sites. Since there are no standards, different manufacturers can differ significantly, because when buying, pay attention to the characteristics of each material being purchased.

Table of thermal conductivity of building materials

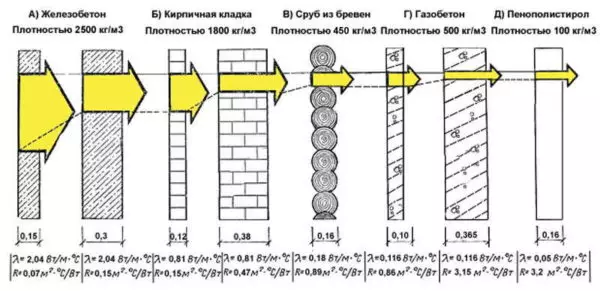

Walls, overlap, floor, can be made from different materials, but it was so it turned out that the thermal conductivity of building materials is usually compared with brick masonry. I know this material everything is easier to conduct associations with it. The most popular charts on which the difference between various materials is clearly demonstrated. One such picture is in the previous paragraph, the second is a comparison of a brick wall and a wall of logs - is shown below. That is why for walls of brick and other material with high thermal conductivity, thermal insulation materials are chosen. To make it easier to select, the thermal conductivity of the main building materials is reduced to the table.

Compare a variety of materials

| Title material, density | Coefficient of thermal conductivity | ||

|---|---|---|---|

| in dry condition | with normal humidity | With high humidity | |

| CPR (cement-sandy solution) | 0.58. | 0.76 | 0.93 |

| Lime-sandy solution | 0.47 | 0,7 | 0.81. |

| Plaster plaster | 0.25. | ||

| Foam concrete, aerated concrete on cement, 600 kg / m3 | 0.14. | 0.22. | 0.26. |

| Foam concrete, aerated concrete on cement, 800 kg / m3 | 0.21 | 0.33 | 0.37 |

| Foam concrete, aerated concrete on cement, 1000 kg / m3 | 0.29. | 0.38. | 0.43 |

| Foam concrete, amateur aerated concrete, 600 kg / m3 | 0.15 | 0.28. | 0.34. |

| Foam concrete, amateur aerated concrete, 800 kg / m3 | 0.23. | 0.39 | 0.45 |

| Foam concrete, amateur aerated concrete, 1000 kg / m3 | 0.31 | 0.48. | 0.55. |

| Window glass | 0.76 | ||

| Arbolit | 0.07-0.17 | ||

| Concrete with natural rubble, 2400 kg / m3 | 1,51 | ||

| Lightweight concrete with natural pimes, 500-1200 kg / m3 | 0.15-0.44 | ||

| Concrete on granular slags, 1200-1800 kg / m3 | 0.35-0.58 | ||

| Concrete on the boiler slag, 1400 kg / m3 | 0.56. | ||

| Concrete on Stone Crubbish, 2200-2500 kg / m3 | 0.9-1.5 | ||

| Concrete on fuel slag, 1000-1800 kg / m3 | 0.3-0.7 | ||

| Ceramic block picked | 0,2 | ||

| Vermiculitobeton, 300-800 kg / m3 | 0.08-0.21 | ||

| Ceramzitobeton, 500 kg / m3 | 0.14. | ||

| Ceramzitobetone, 600 kg / m3 | 0.16. | ||

| Ceramzitobeton, 800 kg / m3 | 0.21 | ||

| Ceramzitobeton, 1000 kg / m3 | 0.27. | ||

| Ceramzitobeton, 1200 kg / m3 | 0.36. | ||

| Ceramzitobeton, 1400 kg / m3 | 0.47 | ||

| Ceramzitobeton, 1600 kg / m3 | 0.58. | ||

| Ceramzitobeton, 1800 kg / m3 | 0,66 | ||

| Current Ceramic Full-Term Brick on the CPR | 0.56. | 0,7 | 0.81. |

| Masonry from the hollow ceramic brick on the CPR, 1000 kg / m3) | 0.35 | 0.47 | 0.52. |

| Masonry from the hollow ceramic brick on the CPR, 1300 kg / m3) | 0.41 | 0.52. | 0.58. |

| Masonry from the hollow ceramic brick on the CPR, 1400 kg / m3) | 0.47 | 0.58. | 0.64. |

| Masonry from full-scale silicate brick on CPR, 1000 kg / m3) | 0,7 | 0.76 | 0.87 |

| Masonry from the hollow silicate brick on the CPR, 11 voids | 0.64 | 0,7 | 0.81. |

| Masonry from the hollow silicate brick on the CPR, 14 voids | 0.52. | 0.64 | 0.76 |

| Limestone 1400 kg / m3 | 0.49 | 0.56 | 0.58. |

| Limestone 1 + 600 kg / m3 | 0.58. | 0.73 | 0.81. |

| Limestone 1800 kg / m3 | 0,7 | 0.93 | 1.05 |

| Limestone 2000 kg / m3 | 0.93 | 1,16 | 1.28. |

| Construction Sand, 1600 kg / m3 | 0.35 | ||

| Granite | 3,49. | ||

| Marble | 2,91 | ||

| Ceramzit, Gravel, 250 kg / m3 | 0.1. | 0.11 | 0.12. |

| Ceramzit, Gravel, 300 kg / m3 | 0.108. | 0.12. | 0.13. |

| Ceramzit, Gravel, 350 kg / m3 | 0.115-0.12 | 0.125 | 0.14. |

| Ceramzit, Gravel, 400 kg / m3 | 0.12. | 0.13. | 0.145 |

| Ceramzit, Gravel, 450 kg / m3 | 0.13. | 0.14. | 0.155 |

| Ceramzit, Gravel, 500 kg / m3 | 0.14. | 0.15 | 0.165 |

| Ceramzit, Gravel, 600 kg / m3 | 0.14. | 0.17. | 0.19. |

| Ceramzit, Gravel, 800 kg / m3 | 0.18. | ||

| Gypsum plates, 1100 kg / m3 | 0.35 | 0.50 | 0.56 |

| Gypsum plates, 1350 kg / m3 | 0.23. | 0.35 | 0.41 |

| Clay, 1600-2900 kg / m3 | 0.7-0.9 | ||

| Clay refractory, 1800 kg / m3 | 1,4. | ||

| Ceramzit, 200-800 kg / m3 | 0.1-0,18 | ||

| Ceramzitobetone on quartz sand with piciation, 800-1200 kg / m3 | 0.23-0.41 | ||

| Ceramzitobeton, 500-1800 kg / m3 | 0.16-0,66. | ||

| Ceramzitobeton on Perlite Sand, 800-1000 kg / m3 | 0.22-0.28 | ||

| Brick clinker, 1800 - 2000 kg / m3 | 0.8-0.16 | ||

| Ceramic facing brick, 1800 kg / m3 | 0.93 | ||

| Laying Laying Middle Density, 2000 kg / m3 | 1,35 | ||

| Sheets of plasterboard, 800 kg / m3 | 0.15 | 0.19. | 0.21 |

| Sheets of plasterboard, 1050 kg / m3 | 0.15 | 0.34. | 0.36. |

| Plywood glued | 0.12. | 0.15 | 0.18. |

| DVP, chipboard, 200 kg / m3 | 0.06 | 0.07 | 0.08. |

| DVP, chipboard, 400 kg / m3 | 0.08. | 0.11 | 0.13 |

| DVP, chipboard, 600 kg / m3 | 0.11 | 0.13 | 0.16. |

| DVP, chipboard, 800 kg / m3 | 0.13 | 0.19. | 0.23. |

| DVP, chipboard, 1000 kg / m3 | 0.15 | 0.23. | 0.29. |

| Linoleum PVC on the heat insulating basis, 1600 kg / m3 | 0.33 | ||

| Linoleum PVC on the heat insulating basis, 1800 kg / m3 | 0.38. | ||

| Linoleum PVC on a tissue basis, 1400 kg / m3 | 0,2 | 0.29. | 0.29. |

| Linoleum PVC on a tissue basis, 1600 kg / m3 | 0.29. | 0.35 | 0.35 |

| Linoleum PVC on fabric basis, 1800 kg / m3 | 0.35 | ||

| Sheets asbetic flat, 1600-1800 kg / m3 | 0.23-0.35 | ||

| Carpet, 630 kg / m3 | 0,2 | ||

| Polycarbonate (sheets), 1200 kg / m3 | 0.16. | ||

| Polystyrevbeton, 200-500 kg / m3 | 0.075-0.085 | ||

| Shelter, 1000-1800 kg / m3 | 0.27-0,63 | ||

| Fiberglass, 1800 kg / m3 | 0.23. | ||

| Concrete tile, 2100 kg / m3 | 1,1 | ||

| Ceramic tile, 1900 kg / m3 | 0.85 | ||

| Tile PVC, 2000 kg / m3 | 0.85 | ||

| Lime Plaster, 1600 kg / m3 | 0,7 | ||

| Stucco Cement-sand, 1800 kg / m3 | 1,2 |

Article on the topic: Siphon for washing machine: What is better to choose?

Wood is one of the building materials with a relatively low thermal conductivity. The table gives an indicative data in different rocks. When buying, be sure to see the density and coefficient of thermal conductivity. Not all of them are, as registered in regulatory documents.

| Name | Coefficient of thermal conductivity | ||

|---|---|---|---|

| In dry condition | With normal humidity | With high humidity | |

| Pine, fir across fibers | 0.09. | 0.14. | 0.18. |

| Pine, spruce along the fibers | 0.18. | 0.29. | 0.35 |

| Oak along the fibers | 0.23. | 0.35 | 0.41 |

| Oak across fibers | 0.10. | 0.18. | 0.23. |

| Cork tree | 0.035 | ||

| Birch | 0.15 | ||

| Cedar | 0.095 | ||

| Natural rubber | 0.18. | ||

| Maple | 0.19. | ||

| Lipa (15% humidity) | 0.15 | ||

| Larch | 0.13. | ||

| Sawdust | 0.07-0.093 | ||

| Tow | 0.05 | ||

| Parquet oak | 0.42. | ||

| Parquet piece | 0.23. | ||

| Parquet packer | 0.17. | ||

| Fir | 0.1-0.26 | ||

| Poplar | 0.17. |

Metals are very well carried out heat. They are often the bridge of cold in the design. And this is also necessary to take into account, eliminate direct contact using heat-insulating layers and gaskets, which are called thermal gap. The thermal conductivity of metals is reduced to another table.

| Name | Coefficient of thermal conductivity | Name | Coefficient of thermal conductivity | |

|---|---|---|---|---|

| Bronze | 22-105 | Aluminum | 202-236 | |

| Copper | 282-390. | Brass | 97-111 | |

| Silver | 429. | Iron | 92. | |

| Tin | 67. | Steel | 47. | |

| Gold | 318. |

How to calculate wall thickness

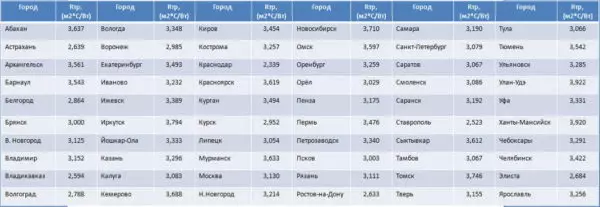

In order for winter in the house there was warm, and in the summer cool, it is necessary that the enclosing structures (walls, gender, ceiling / roof) must have a certain thermal resistance. For each region, this value is its own. It depends on average temperatures and humidity in a specific area.

Thermal resistance protects

Constructions for regions of Russia

In order for the heating bills to be too large, it is necessary to select building materials and their thickness so that their total thermal resistance is not less than specified in the table.

Article on the topic: Choose the best washbasin for giving

Calculation of the thickness of the wall, the thickness of the insulation, the finishing layers

For modern construction, the situation is characteristic when the wall has several layers. In addition to the supporting structure, there is insulation, finishing materials. Each of the layers has its thickness. How to determine the thickness of the insulation? The calculation is easy. Complete from the formula:

The formula for calculating thermal resistance

R is thermal resistance;

p - layer thickness in meters;

K is the coefficient of thermal conductivity.

Previously need to decide on the materials that you will use during construction. Moreover, it is necessary to know exactly what type of wall material will be insulation, decoration, etc. After all, each of them contributes to the thermal insulation, and the thermal conductivity of building materials is taken into account in the calculation.

First, the thermal resistance of the structural material is considered (from which the wall, overlap, etc.) will be built, then the thickness of the selected insulation is selected "along the residual" principle. It is still possible to take into account the thermal insulation characteristics of the finishing materials, but usually they are "plus" to the main. This is how a certain stock is "just in case". This stock allows you to save on heating, which subsequently has a positive effect on the budget.

An example of calculating the thickness of the insulation

We will analyze on the example. We are going to build a wall of brick - in a half brick, we will warm mineral wool. On the table, the thermal resistance of the walls for the region should be at least 3.5. The calculation for this situation is shown below.

- To begin with, we calculate the thermal resistance of the brick wall. A half brick is 38 cm or 0.38 meters, thermal conductivity coefficient of brick masonry 0.56. We consider it according to the above formula: 0.38 / 0.56 = 0.68. Such thermal resistance has a wall of 1.5 bricks.

- This value is taking away from the general thermal resistance for the region: 3,5-0.68 = 2.82. This magnitude needs to be "breed" with thermal insulation and finishing materials.

All enclosing structures will have to count

- We consider the thickness of the mineral wool. Its thermal conductivity coefficient is 0.045. The layer thickness will be: 2.82 * 0.045 = 0.1269 m or 12.7 cm. That is, to ensure the required level of insulation, the thickness of the mineral wool layer must be at least 13 cm.

If the budget is limited, mineral wool can be taken 10 cm, and the missing finishing materials. After all, they will be from the inside and outside. But, if you want the account for heating to be minimal, it is better to finish the "plus" to the settlement value. This is your reserve during the lowest temperatures, since heat resistance standards for enclosing structures are considered at an average temperature for several years, and winter is abnormally cold. Therefore, the thermal conductivity of building materials used for finishing is simply not taken into account.