For many millennia, wooden houses were used by people, and their popularity in the 21st century and comes to a new level. Before folding a log house, you need to know a lot of things. There are many advantages in this kind of houses: environmental friendliness, design, easily warms and retains heat for a long time, breathes, so that there are always fresh air inside.

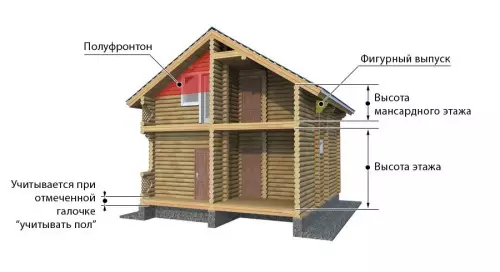

Parameters for building a house from a bar.

Preparatory work

Tools and materials:

- roulette;

- shovel;

- sand;

- water;

- Edged board;

- rod reinforcing;

- Bulgarian;

- welding machine;

- Hammer with nails;

- gas-burner;

- Ruberoid.

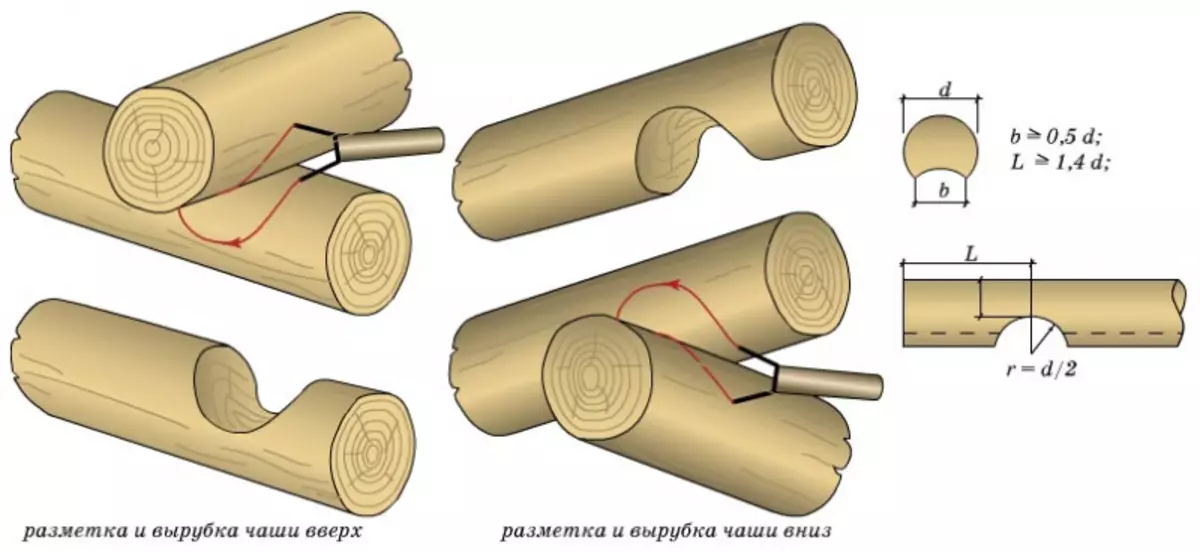

Cup diagram of a log with an angular wrist.

At the very beginning, the foundation is made under the log house, and its bulleting can be minimal, but it will have to raise over the surface of the earth, so that the seasonal moisture does not destroy the wood. An optimally fits fine-breeding belt foundation, which will not need a lot of time and effort.

For a start, a trench is turned around in a perimeter in a depth of 35 cm and in a width of 40 cm, and at least 2 commoners are formed inside to increase strength. After the required trench is dug, you need to align its walls and the bottom part, so that the fused solution will be highly reliable.

A sandy pillow is 5 cm on the bottom and watering with water. In the meantime, water dries (2-3 days), you need to prepare the remaining items.

Now you should make a formwork. For it, a cutting board of 25x150 mm will be required, and the height of the shields will be 0.7 m. The formwork is desirable to make it immediately to the entire construction, so that later it does not have to fill parts. All the attachments of the boards are carried out on nails, because with screws will have to spend 2-3 times more time so as not to split the boards.

The reinforcing frame goes ribbed rod 10 mm. In this case, the process looks standard way:

Article on the topic: AUU - Effective saving of thermal energy

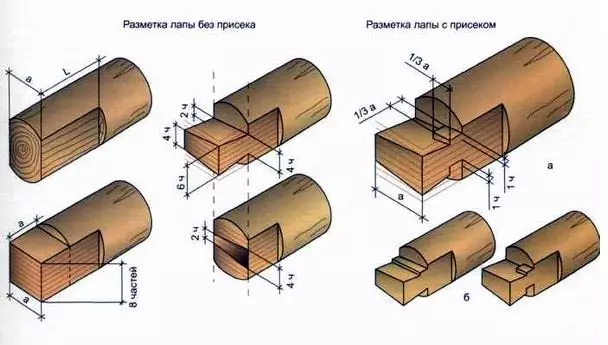

Figure 1. Log marking diagram when cabping in paw.

- 5 long parallel rods are folded in 10 cm increments.

- Perpendicular to the rods 60 cm in a step of 30 cm.

- Each joint is fixed by electric arc welding.

- It is manufactured by an identical lattice.

- With the help of rods at 25 cm, all parallel junctions are combined into one system. It is desirable to spend this step directly at the installation site, because Even 2 people will not always be able to raise the finished design, and not everyone can use the truck crane.

In the manufacture, you need to be attentive so that the metal does not touch the formwork and sand. In order to raise the armature over sand, you need to use broken brick or special plastic sprockets. From above, you need to screw the rods with a step in 1 m in order to provide a high-quality junction between rounded and concrete.

Now you can pour a solution of concrete M300-350, after which we boldly leave for drying on 28 days. After this time, the formwork is dismantled, and all open areas of concrete are laid in front of the rubberoid and are migrated to the gas burner. Steel rods also need to be covered with waterproofing.

Primary activity

Tools and materials:

- ax;

- Rounded;

- roulette;

- knife;

- tow.

Figure 2. Connection diagram in paw with spike.

Now you can make a log house from a rounder. There are only 2 options for cutting, which are especially popular: Russian and Canadian. Externally, it is identical, but in practice the Canadian bowl (Fig. 1) is universal, because It allows you to harvest wood in any season, and after shrinkage (up to 10 cm) there are no cracks. There are 2 ways of cutting - in the bowl and in the paw (Fig. 2), but because of the reliability it is especially popular.

There is a small nuance that is not all those who are not all, because of what the tree is sometimes judged negative: all elements need to shape with an ax, because In these places, the likelihood of rotting decreases many times. In no case cannot be used by rounded options, because In industrial processing from wood, a protective layer is removed. The only plus of the rounded version is its thermal insulation that is better than any analogues.

Article on the topic: how to close the door slopes

The glued bar is an intermediate link, i.e. It has intermediate strength characteristics, and together with this average thermal insulation and mass. It differs in the way of the joint - vertical. This method does not need to cut down the grooves at the edges, because He has a solid groove along the entire length, into which you can install the following similar instance.

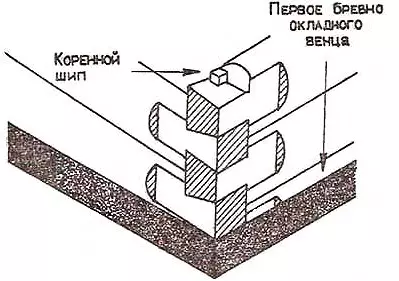

Scheme of the vertical section of the interventovation compound.

After the entire log house is made, you can start cutting out the doors and windows. This step is very unusual in modern realities, but it is he who will provide perfect quality. For strength, it is necessary to pave one log in the center.

The house is ready, windows and doors are installed, the roof is covered, but you need to finally delimit the inner and external space. For this, all the slots of the packles are caught in the Siruba. Such a process is carried out with the help of an ordinary knife. From above, any finish is recorded, but in the first 3 years it is better to use something simple, because Need to follow the seams.

Additional aspects

Ceramzite serves as insulation for the floor, but if you wish to use any other insulation. For clayzit, it is initially a waterproofing, which will go on the walls, then goes the insulation layer, and then the waterproofing again, but already with a bend. From above the screed is formed.

The furnace indoors is placed at a distance of at least 15 cm from the walls, but better in the old traditions in the center of the room. Such precaution will allow not to think about possible fires.

Before folding the log house from the round, you need to know not only the quality of wood, but also the time of cutting.

To be confident in quality, it is better to take the easiest round of an ax, which does not undergo special treatments tool.

It is he who will serve several centuries if it is true.