Smooth waters close to the surface of the soil deliver a lot of trouble to land owners. They gradually destroy the foundations of buildings, contribute to the lap soil. For the removal of groundwater, closed drainage systems consisting of pipelines and drainage wells are mounted. You can equip such a system yourself, just like installing a drainage well with your own hands. Such wells on the site may be several pieces, depending on its size and the composition of the soil.

Design and purpose

We study more Drainage Well: What is it and what functions does it perform?

This structure is a decisive reservoir opened in the soil. The well made from the mine, the upper hatch and the bottom. There are no recessed bottoms of the bottom. Well allows you to accumulate excessive moisture entering it from pipelines, control the degree of contamination of drainage pipes, track the degree of drainage of water.

The drainage well on the site is the most important element without which the drainage system would quickly lose their functionality, and stopped performing its purpose.

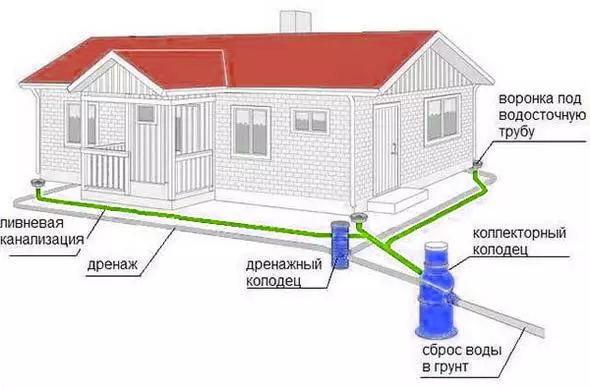

The use of drainage wells in the drainage system of the house

Types of drainage wells

There are several options for the execution of drainage wells, each of which performs certain tasks. Consider these species in more detail:

one. Watching (inspection) well . Its purpose is to inspect and clean the closed pipes. For collecting water, such structures are not intended. Watching wells for a small diameter drainage (up to 46 cm) are used to flushing pipelines, while more overall products with a diameter of 0.9-2 m allow us to go inside people for cleaning the cleaner events. Inspection wells are installed in places of pipe compounds, as well as on very long rectilinear areas of the drainage pipeline.

Rotary auditing wells are often used, installed at the intersection of several drainage pipes, in angular points, as well as on the rotations of pipelines.

In the photo Rotary inspection well plastic

2. Collector (accumulative) well . It is installed when the soil on the clay area, which is not able to absorb a large amount of moisture. It also applies in cases when it is impossible to reset the excess moisture outside the site. The drainage well device involves the flow of water from the drainage system, followed by its spending for all sorts of economic needs. Such wells are hermetic. There may be several similar structures on the site. If the well is represented in a single number, several drainage pipes are suspected simultaneously.

Article on the topic: Floor alignment plywood: how to level the lags old, concrete doom and a wooden screed with plywood

The diameters of plastic pipes for the manufacture of such wells start from 57 cm. The deeper will be the tank, the slower it will be filled, and it is installed in the lowest point of the site, below the drainage pipes.

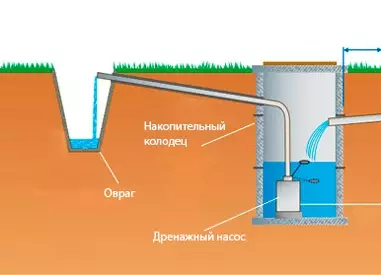

Devraging well with pump

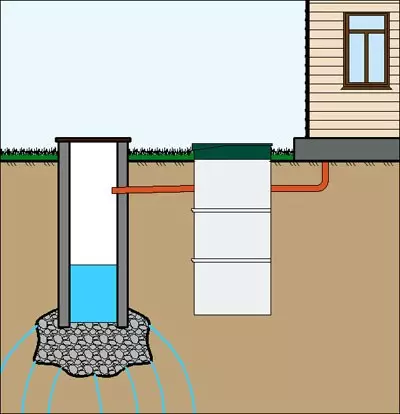

3. Absorption (filtering) well . Its use is advisable in the case when bringing drainage water beyond the site or to the central sewer system is not possible.

Tip: Use this kind of wells if the total volume of effluent on your site is not too big (up to 1 cubic meter per day).

Absorption well for drainage usually has depth of more than 2 meters . The bottom of the structure is covered with a layer of broken brick, slag or gravel with a thickness of about 30 cm, which contribute to the suction of water into the ground. The upper part of the well is covered with geotextiles, on top of which the soil layer is poured.

The wells of the absorbing type are often arranged as the last stage of wastewater treatment after septic

The use of the filter well is justified on sandy and sampling soils having a high absorption capacity.

Tip: If the walls of the absorption well have slit, it is recommended to lay a layer of geotextile on them, which will filter water penetrating through them.

What materials are manufactured by wells

Drainage wells can be manufactured from various materials that differ in their properties:

one. Concrete. This is a traditional material for the manufacture of drainage wells. The easiest way to assemble the construction of concrete rings installed one on top of the other. The walls and bottom can also be flooded with concrete solution, especially if the drainage well is made with their own hands. To do this, you will need to construct formwork. Concrete refers to durable and durable materials, but with a long contact with water, it begins to gradually crumble and crack.

2. Brick. They lay the walls of the well, the bottom of which is poured by concrete. The brick is less durable than concrete, but it is convenient to put it even alone. For the manufacture of drainage systems is rarely applied.

Article on the topic: How to properly prepare water for the heating system?

3. Plastic (polymeric) wells. They are increasingly conserved with other materials used in drainage systems. Plastic containers have a number of benefits:

- Resistance to extreme temperatures. They can be operated in the temperature range of -60 + 50 degrees;

- Plastic is a lightweight material, so the installation of such a structure can be carried out independently, without attracting construction equipment;

- Installation of the drainage well made of plastic is performed quickly and simply. If necessary, the material is easily cut to the desired dimensions, which is impossible to produce with concrete rings;

- inert to different aggressive substances;

- They are not terrible corrosion and oxidation;

- have a strength comparable to metal and concrete;

- perfectly carry mechanical and hydraulic loads;

- Plastic containers do not rot, are not damaged by rodents and insects;

- plastic containers can be placed at any depth and in the soil with any structure;

- The durability of the plastic reservoir is about 50 years.

An example of a complete set of a finished plastic well for drainage

Most often, corrugated pipes of various diameters made from polyvinyl chloride are used as drainage containers. The drain-looking well, or having another destination made from such pipes, has sufficient rigidity to counteract it from the ground with groundwater.

Independent installation of drainage wells

Consider how to make a drainage well with your own hands. Depending on the type of well, the methods of its manufacture are different.Installation of a storage well made of plastic

The material for the manufacture of such a well can be a corrugated plastic tube of various sizes.

Important: Installing the wells of this type is necessary below all drainage pipelines, providing an unimpeded flow of water to them.

1. It turns out the pit for a future tank.

2. The necessary length of the corrugated pipe is measured, after which it is pruning.

3. The sand pillow falls asleep into the pit or a solid concrete base is created.

4. The prepared container is set to the prepared kit, having taps for connecting pipes. Holes for input pipes can be done after installation of the container per permanent place. Many finished wells already have special taps, so connecting them to the drainage system is easy.

5. With bitumen mastic to the pipe, a plastic bottom is glued.

Article on the topic: Interesting ideas for masking outlets

6. The drainage pipes and sealing of the gap are input.

7. The gaps between the walls of the well and the pita are covered with rubble, sand or sand mixture with cement.

Tip: Inside the well, it is desirable to immediately place the drainage pump, through which water pumping will be made. You can also use a submersible pump that will go to the well manually, as needed, either the surface type pump.

8. From above, the accumulative tank is covered with a lid to prevent its contamination and on this installation of a drainage well can be considered made.

The device of the drainage well with the hands of the viewing type is made by a similar scheme, except for installing the pump. There is also no need to place it in the lowest point of the site.

Installation of the drainage polymer well

Installing a well made of concrete rings

For the manufacture of concrete wells, it is better to use reinforced rings with a lock. If there are no, the usual concrete products will fit. The thicker they will be, the longer they will serve.

For a device of a drainage well made of concrete rings, it is recommended to use products with locks

The work is performed using special loading equipment in such a sequence:

1. It is prepared by the pitual size.

2. At the bottom of the bottom, sand or gravel is embanked. If the filter container is manufactured, the thickness of the pillow must be at least half a meter.

3. The first ring with the bottom is stacked on the pillow. If the rings are used without the bottom, then a concrete screed is made from the bottom of the first ring.

4. The next rings are stacked on top of the previous ones. When installing concrete rings, seams are provided between them with concrete solution or bitumen mastic.

5. When the last ring is installed, the holes are done in it (if there are no more) to enter drainage pipes.

6. In the hole openings, the pipes are displayed, after which all the joints are carefully sealing.

7. The pad is installed on top of the well. You can use plastic or metal covers, as concrete products are too heavy.

8. The empties between the walls of the pit and concrete rings are covered with sand, gravel or rubble.

The arrangement of the drainage well is not a very difficult task. With such work, you can cope with yourself, especially when installing plastic products.