Steel pipes are gradually crowded from the market: there are decent competitors who cost less, they are easier to be mounted, they are no less. For example, from metal plastic make a hot and cold water supply, the heating system. How to carry out the installation of metal-plastic pipes, which fittings when using how to use them to connect the segments into a single whole - about all this and it will be discussed.

Types of fittings for metal-plastic pipes

The structure of metal-plastic pipes is such that it is impossible to boil them or solder. Therefore, all branches and some bends are made using fittings - special elements of different configuration - tees, adapters, corners, etc. With their help, a system of any configuration is collected. The lack of such technology is the high cost of fittings and the time that will have to spend on their installation.

Approximate range of fittings for mounting metal-plastic pipes with press

Plus of metal-plastic pipes in the fact that they are well bend. This allows you to use fewer fittings (they are expensive). In general, fittings for metal-plastic pipes are:

- Crimp.

- Press fittings (press).

Solve what type of fittings to use simply. Crimpters are used for pipelines to which there is always access - over time, the connections are required to pull up. Press can be tinted. That's the whole choice - you need to know what type of installation of metal-plastic pipes will be on a particular site.

Appearance of some fittings with naked nuts - screw or crimping

The overall drawback of metal-plastic pipes - due to the design of fittings on each compound, the segment of the pipeline occurs. If the connections are a bit and the track is notterenen, there can be no consequences. Otherwise, it is necessary or an increase in the cross-section of the pipeline, or a pump with greater power.

Preparation for mounting

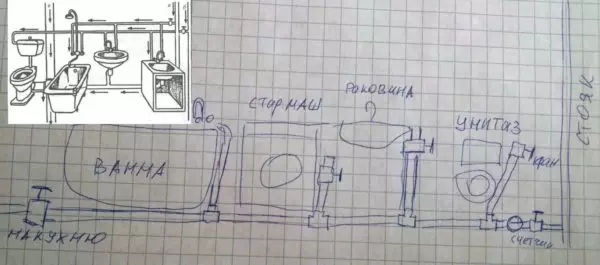

First of all, it is necessary on a sheet of paper to draw the entire system of water supply or heating. In all places of branches, draw the fitting that you want to install and sign it. So they are convenient to count.Instruments

To work except the pipe and purchased fittings will need:

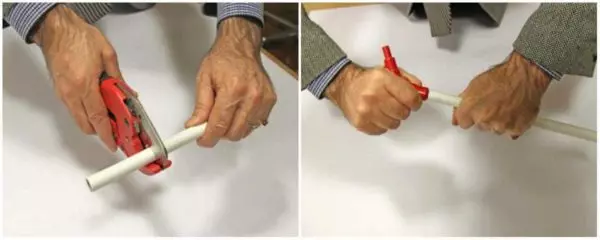

Truborez. The device resembling scissors. Provides the correct location of the cut - strictly perpendicular to the surface of the pipe. It is very important.

This tool cuts metal-plastic (and not only) pipes

Calibrator (caliber) for metal-plastic pipes. In the process of cutting, the pipe is slightly flattened, and its edges are slightly bend inside. The calibrator is just needed in order to restore the shape and level the edges. Ideally, the edges are unrolled out - so the connection will be more reliable.

Types of calibrators

- Zenker - device for removing the chamfer. A construction knife or a piece of sandpaper is also suitable. Often calibrators have a ledge for chamfering, so without this tool you can do.

- Fittings installation equipment:

- For crimping, we need two spanners of a suitable size;

- For press fittings - crimping pliers.

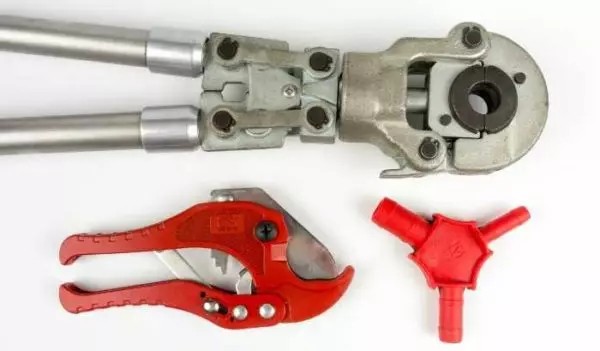

Manual crimping pliers or press, device for cutting MP pipes and calibrator. Actually this is the entire tool required for the installation of press fittings and installation of metal-plastic pipes.

In principle, everything. Instead of pipe cut, you can use a saw blade with metal, but it will be necessary to make sections strictly perpendicular to the surface. If you trust your charming, take a carpentry stub.

Procedure for training

Sold metal-plastic pipes of a small diameter in the bays. Before mounting, cut a piece of the required length from the bay. At the same time, it is necessary to consider the length that comes to the fitting. That is, it is necessary to cut off a piece with a slight margin - in 1.2-1.5 cm.

The edges of the segment are inspected if there are burgers (with a cutting pipe cut, it does not happen, this is a lack of cutting with a saw), they are aligned. Next, with the help of a trimmer or a piece of sandpaper, the chamfer is removed - the plastic is raised at the corner of both inside the pipe and outside.

Cut, calibrate, remove the chamfer

After that, they take a calibrator, with an effort driving it into the pipe and turning, align the geometry, at the same time straightening the "crushed" inside the edge. After that, you can start the installation of metal-plastic pipes and installing fittings.

How to align a piece of metal-plastic pipe

As already talked, this type of pipes goes to the bays, that is, they are twisted. Cutting off a piece, hand you stretch it a bit, but how to achieve perfect evenness. This is important if the mounting of the pipeline is open. The recipe is simple:

- Find a smooth board or a piece of chipboard, plywood, etc.

- The aligned segment is wrapped in a soft fabric (you can in the old terry towel).

- On the board roll out, smooth.

Usually, when the water supply is wiring, in places the track has to be bending, lay straight areas

After the segment becomes smooth, you can calibrate its edges.

Installation of metal-plastic pipes with compression fittings

Compression fittings consist of several parts. The base is cast carbon case. There is also a crimp ring that fixes a piece of pipe on the fitting and a cape nut that clamps the connection. An important detail is a sealing ring that provides tightness.

This method of installation is good because there is no special equipment. The second plus is the collapsible connection and, if necessary, can be replaced fitting. If he failed or has the need to change the pipeline configuration. And it is very convenient.

But there is a disadvantage: from time to time on a thread occurs. It is eliminated by everything simply - tightening to the half-turn. But because of this, all connections should be accessible and aligning them. Also strains the need to check - flowed, not flowed. Not everyone likes it.

So the compression fittings look like

Assortment of fittings is a wide corner, tees, crossmen, adapters (from one diameter to another). And all this with different angles, in different diameters.

Installation of metal-plastic pipes on compression fittings begins with the fact that the cape nut and the crimping ring is removed, the presence of a sealing gum is checked. After that, the assembly itself begins:

- Nut and ring wear on the pipe.

- The segment is stretched to fitting until it stops. The emphasis is indicated by a special small border protrusion.

- The ring is tensioning too until the fitting stops.

Before tightening the naika

- A tight nut is tightened. First with hands, the connection of metal-plastic tube pulls up with two keys. One holds the fitting body, the second turns the cape nut.

On this, everything, the process of installation of compression (screw, threaded) fitting is completed. There is only one nuance: if you pour antifreeze into the system, change the gasket immediately. Those that come in the kit will flow with non-freezers very quickly. Place paronit or teflon. Only they can provide tightness. In general, for systems with antifreeze it is better to use press fittings. They definitely do not flow (if they are properly compressed).

Installing crimp (press or push) Fittings on MP pipes

Installation of metal-plastic pipes using crimp fittings requires special ticks. They are manual, there is electric. Any is equipped with a set of linings for different diameters. Manual, naturally, cost cheaper. This equipment is not necessary to buy - it will be needed only once. Much more profitable to rent.

Press fitting for MP pipes

A press fitting of two parts is the actual housing and crimping sleeve. Before connecting metal-plastic pipes, carry out a cut preparation. It is the same as when using compression fittings, but the chamfer is removed only from the inside. Next, the procedure for such:

- Sleepers put on the pipe.

- The fitting establishes the gasket to prevent electrochemical corrosion.

- Tuba is put on the fitting - until it stops. On the fitting housing there is a hole in which the edge of the pipe should be seen.

- Take ticks in which suitable lining (the desired diameter) are installed. Pliers are installed close to the edge of the fitting, connecting the pen handle together crimp the item. As a result, two concave bands should be clearly visible on the sleeve. Their depth should be the same. After crimping fittings can rotate around the pipe.

On this, the installation of metal-plastic pipes using the press fitting is complete. A similar junction withstands pressure up to 10 atm, which is enough for most systems. Not suitable for home heating systems with floors. More than 16. They have pressure in the system may be greater.

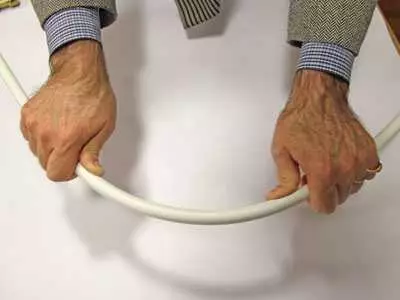

How to bend a metal-plastic pipe

Often the installation of metal-plastic pipes occurs the need to bend the pipe. You can do it with your hands or with a spring. It's easier and faster to work with a spring, but it must be bought (it is inexpensive). The spring is inserted into the pipe and bends in the desired direction. The pipe repeats the bending, the spring is removed. Bending metal-plastic pipes with a spring are simple - no more effort required, the actions are easily controlled, it is possible to adjust the result.

What is good this way - you will not be able to overcertrine the walls, which happens when an excessive force is applied in the manual method. Also, it is not possible to make a sharper bend (with a radius less than the minimum) and squeeze the walls on the bend, catching the passage section.

Spring for flexible metal-plastic pipes

Hands of bending MP pipes must be gradually. Take your hands from two sides from the place of bend (at the same distance from the center of the future arc), the thumbnails are backing the pipe. In this position, start the edge to lower down, at the same time pulling the top fingers upstairs.

Manual bending of metal-plastic pipes

With this method, sometimes from excessive force, the pipe loses its geometry. This negatively affects its bandwidth. It is impossible to put such sections in plumbing or heating. To avoid such situations, the scene is heated. This can be done only with the help of a construction dryer. It is impossible to use open fire. Preheated plastic bend simply. At the same time, it is not silent (the main thing is not to overdo it).

Methods of bending MP pipes

Another way to avoid deformation is to pour into the sand. It will not give the walls to shrink.

How to fix the walls

With the opening of the pipeline, it is required to somehow fix on the walls. Typically, special plastic clips are used for this. They are single - for laying one piping thread. Usually used when laying the water supply. There are dual - most often they are installed on heating - the supply and return in the two-pipe systems are in parallel.

Clips for mounting metal-plastic pipes on the wall

These clips are installed through each meter (more often). The hole is drilled in the wall in the wall, the dowel of the required type is inserted (it is selected depending on the type of material from which the walls are made). Large load is not foreseen, but a water supply and heating looks much more attractive if everything is lured exactly as Lineshek.

Non-standard connections: with metal pipes, transition to another diameter

When replacing the water supply or heating, it is often necessary to connect metal and metal-plastic. Most often it happens on a tap from the riser. In this case, the metal tube is cut at some distance - 3-5 cm, thread is cut on it. Next, the thread is screwed down with a feather nut (Cangua) or internal thread. Next, the installation of metal-plastic pipes is on ordinary technology.

Some types of fittings that can be used when moving from metal to metal plastic

The fitting is selected on the diameter of the metal pipe, and the thread on the adapter must be internal - the outer is cut on the pipe. This connection requires a seal. Complete with flax and mold packing paste or simply use fum-tape.

The connection of two pipes of different diameters occurs just as well. Only the appropriate fitting adapter with nuts / nipples of a suitable diameter is required.

Example Water supply system

First, draw a water supply layout plan. You can do it on a sheet of paper, denoting the necessary fittings. Please note that the installation of the cranes requires a carving fitting at the end. Cranes are needed on the discharges to household appliances and to plumbing devices, to heating radiators. This makes it possible to turn off the devices without overlapping the entire system entirely. Type of thread and select it depending on the type of crane used.

An example of water supply system on metal-plastic pipes

Also, adapter fittings are needed before and after the meter (water or heating depends on the type of system). Drawing a detailed plan, put sizes in all areas. For this drawing, you think how much and what you need. Fittings can be purchased strictly on the list, and the pipes are preferably taken with some reserve. First, you could be mistaken when measured, secondly, in the absence of experience, you can spoil some piece - cut down less than it is necessary or improved, etc.

Agree on the possibility of exchanging

When buying everything you need to agree with the seller that, if necessary, you can change / return some fittings. Even professionals are often mistaken with them, and one who decided to make a wiring of the water supply system or heating from metal plastic with their own hands and is suppressed. Nobody will accept the remnants of the pipe, and fittings are easily. But for the guarantee, save the check.

Sometimes it is convenient to use collectors. They allow you to connect several consumers in parallel. There are collectors for water supply and heating (with a warm floor laying)

When and how to start work

Having come home, spread the fittings, proceed: the installation of metal-plastic pipes in the summer can be done immediately, in the winter it is necessary to wait for a while (clock 12), until all the elements are warm to room temperature. Cut with just one segment of the pipe of the desired length. This is a little longer, but they definitely not confuse. Further actions depending on the type of fittings selected.

Wiring heating with metal-plastic pipes is made only on press fittings

After the installation of metal-plastic pipes is completed, the pipeline is checked. If it is a plumbing, just open the tap at the entrance. It is necessary to do it gradually and smoothly. The system will immediately begin to fill with water. If nothing else flowed - you did everything right. If some connections flowed, they need to be altered - if press fittings were used, or tighten - if the assembly was on crimping connectors.

If the heating system was assembled from metal-plastic pipes, before starting it, it should be placed - to experience with high pressure by posting cold water into the system. If the test has passed successfully, you can make a trial launch of heating.

Video on the topic

Once again how to properly install metal-plastic pipes will be explained by Valtek specialists (VEKTEK), the products of which are considered one of the best in this market.

Article on the topic: Wiring under plasterboard: deposit correctly