During the construction and improvement of the house, the pipes are not always used to transport liquids or gases. Often they act as building material - to create a frame of various buildings, supports for canopies, etc. When determining the parameters of systems and structures, it is necessary to calculate the different characteristics of its components. In this case, the process itself calls the calculation of the pipe, and it includes both measurements and calculations.

What do you need calculations of pipe parameters

In modern construction, not only steel or galvanized pipes are used. The choice is already quite wide - PVC, polyethylene (PND and PVD), polypropylene, metalplastic, corrugated stainless steel. They are good in that they have not such a large mass as steel analogs. However, when transporting polymeric products in large volumes to know their mass is preferably - to understand what kind of car is needed. The weight of metal pipes is even more important - delivery is considered on tonnage. So this parameter is preferably controlled.

What can not be measured can be calculated

Know the area of the outer surface of the pipe is necessary for the purchase of paint and thermal insulation materials. Only steel products are painted, because they are subject to corrosion in contrast to polymer. So you have to protect the surface from the effects of aggressive media. They use them more often for the construction of fences, frameworks for housekeeping (garages, barn, arbors, cabins), so that operating conditions are heavy, protection is necessary, because all frames require coloring. Here it will be necessary to the area of the painted surface - the outer area of the pipe.

When building a water supply system for a private house or cottage, pipes are packed from a water source (well or well) to the house - underground. All the same, so that they do not frozen, insulation is required. Calculate the amount of insulation can be the burden area of the outer surface of the pipeline. Only in this case it is necessary to take a material with a solid reserve - joints should overlap with a solid reserve.

Article on the topic: How to cover the wooden floor: how to treat a gender, wax and pine coating, wood processing

The pipe cross section is necessary to determine throughput - whether this product will be able to carry out the required amount of fluid or gas. The same parameter is often needed when choosing a diameter of pipes for heating and water pipeline, calculating the performance of the pump, etc.

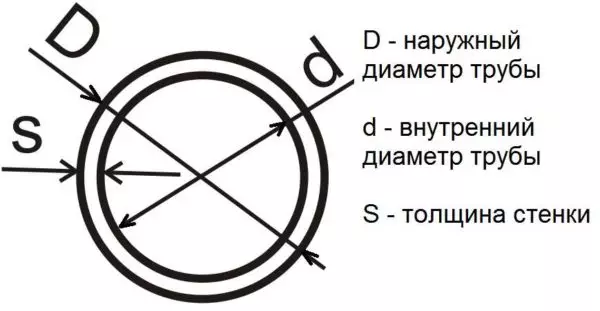

Internal and outer diameter, wall thickness, radius

Pipes are a specific product. They have an internal and outer diameter, as they have thick, its thickness depends on the type of pipe and the material from which it is made. In technical characteristics, the outer diameter and the wall thickness indicate more often.

Inner and outer diameter of the pipe, wall thickness

Having these two values, it is easy to calculate the inner diameter - from the outer to take away the double wall thickness: d = d - 2 * s. If you have an outer diameter of 32 mm, the wall thickness is 3 mm, then the inner diameter will be: 32 mm - 2 * 3 mm = 26 mm.

If, on the contrary, there is an inner diameter and wall thickness, and you need an outdoor - to the existing value, add double stacks twisted thickness.

With radiuses (denoted by the letter R) Even easier - it is half of the diameter: R = 1/2 D. For example, we will find a pipe radius with a diameter of 32 mm. Just 32 divide for two, we get 16 mm.

Measurement calipers more accurate

What if the technical data are no pipes? To measure. If a particular accuracy is not needed, the usual line is suitable, for more accurate measurements it is better to use a caliper.

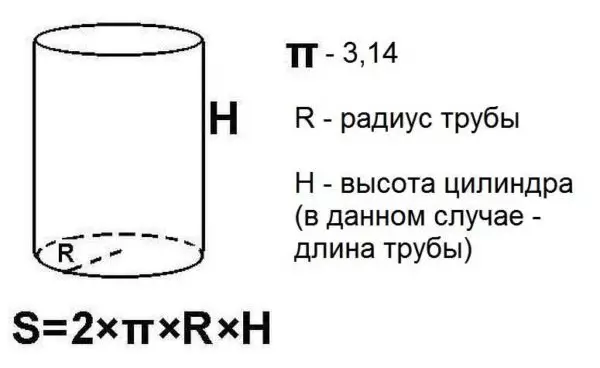

Calculation of the surface of the pipe

The pipe is a very long cylinder, and the area of the pipe surface is calculated as the area of the cylinder. For calculations, the radius will be required (internal or external - depends on which surface you need to calculate) and the length of the segment you need.

Formula for calculating the side surface of the pipe

To find the side area of the cylinder, turn the radius and the length, the resulting value is multiplied by two, and then - by the number "PI", we obtain the desired value. If you wish, you can calculate the surface of one meter, then it can be multiplied by the desired length.

Article on the topic: Practical curtains for the bathroom

For example, we calculate the outer surface of a piece of pipe with a length of 5 meters, with a diameter of 12 cm. For a start, calculated the diameter: we divide the diameter by 2, we obtain 6 cm. Now all the values should be brought to one units of measurement. Since the area is considered in square meters, then the centimeters are translated into meters. 6 cm = 0.06 m. Further we substitute everything in the formula: S = 2 * 3,14 * 0.06 * 5 = 1.884 m2. If rounded, it will turn out 1.9 m2.

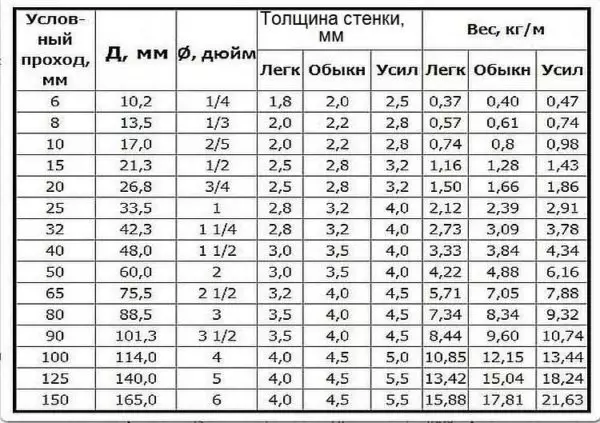

Weight calculation

With the calculation of the weight of the pipe, everything is simple: you need to know how much the traffic point meter weighs, then multiply this magnitude to the length in meters. The weight of round steel pipes is in reference books, since this type of metal is standardized. The mass of one rose meter depends on the diameter and the thickness of the wall. One moment: the standard weight is given for steel density of 7.85 g / cm2 is the appearance recommended by GOST.

Weight Table Round Steel Pipes

In the table D - the outer diameter, the conditional passage is the inner diameter, and another important point: the mass of ordinary steel rolled products is indicated, galvanized by 3% harder.

Square Square Pipe Weight Table

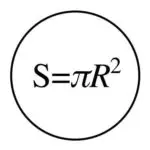

How to calculate the cross-sectional area

Formula of finding a round tube cross section

If the pipe is round, the cross-sectional area should be considered according to the formula of the area of the circle: S = π * R2. Where R is a radius (internal), π - 3.14. Total, it is necessary to build a radius in a square and multiply it by 3.14.

For example, a pipe cross section with a diameter of 90 mm. We find a radius - 90 mm / 2 = 45 mm. In centimeters it is 4.5 cm. We are erected into a square: 4.5 * 4.5 = 2.025 cm2, we substitute in the formula S = 2 * 20.25 cm2 = 40.5 cm2.

The cross-sectional area of the profiled pipe is considered by the formula of the rectangle area: S = A * B, where a and b - the length of the side of the rectangle. If you count the cross section of the profile of 40 x 50 mm, we obtain S = 40 mm * 50 mm = 2000 mm2 or 20 cm2 or 0.002 m2.

Article on the topic: How to install beacons? Proper installation of lighthouses on the wall under the plaster

How to calculate the volume of water in the pipeline

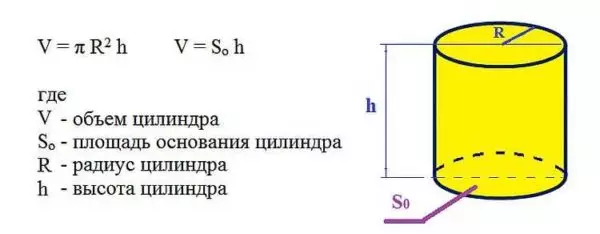

When organizing the heating system, you need such a parameter as the volume of water that will fit in the pipe. This is necessary when calculating the amount of coolant in the system. For this case, the formula for the volume of the cylinder is needed.

Formula for calculating the volume of water in the pipe

There are two ways: first calculate the cross-sectional area (described above) and multiply it to the length of the pipeline. If you consider everything according to the formula, you need the inner radius and the total length of the pipeline. Calculate how much water is placed in a system of 32 millimeter pipes with a length of 30 meters.

First, we will transfer millimeters into meters: 32 mm = 0.032 m, we find a radius (divide in half) - 0.016 m. We substitute in the formula V = 3.14 * 0,0162 * 30 m = 0,0241 m3. It turned out = just more than two hundredths of the cubic meter. But we are accustomed to the volume of the system to measure liters. For cubic meters to transfer to liters, you must multiply the resulting digit to 1000. It turns out 24.1 liters.