Cellic concretes are used for a long time, but with the development of technologies, the scope of application is expanding. If earlier the house of aerated concrete was rarely built, then today this material is already used in 15-20% of new buildings. Build as cottages of temporary accommodation and capital houses. Everything is explained by the availability of material at the price, good heat engineering characteristics, easy and fast laying.

A house of aerated concrete is built with a small number of floors: up to 3

Foundation for a house of foam blocks

As you know, foam concrete blocks are distinguished by low weight. On the one hand, this is good: it is easier to work easier and the foundation for such a building is required with a smaller carrier ability, and, it means, and cheaper. But, on the other hand, when moving the foundation of the wall of the wall because of a small weight cannot "press" processes, like a heavier brick or compensate them as wood. What means that the requirements for the foundation under a gas-concrete house are increased: even minor miscalculations lead to the occurrence of cracks, "treat" which is very expensive. Therefore, it is better not to save on the project: it turns out more expensive.What type of foundation to use

What foundations are made under a house of aerated concrete. On the soils that are not inclined to begged, the monolithic belt foundation is usually made. Depth - below the level of fruit of the soil and in any way differently. By virtue of its design, the reinforcement of the tape will compensate for all the arising loads of the radiation.

If the depth of the primer of the soil is 2 meters and more, the ribbon foundation becomes too expensive. In this case, when locked at this level of soils with a normal bearing ability, a pile-painted foundation is made under the house of aerated concrete. In this case, without frames, it is not necessary to do: it compensates for uneven moves, which often arise on the pile foundation: one pile more rose more, the other is smaller. Without scolding, this will lead to the appearance of cracks, because its device for walls from this material is required.

What is the foundation for the house from aerated concrete decide depending on the soils on the plot

The most expensive, but also the most stable damage - the foundation in the form of a monolithic plate. It is put on soils with a small bearing ability - peatlands, fine-grained bulk sands. It may turn out that it is cheaper compared to the belt foundation, with the depth of the embedding more than 2 meters. In this case, the stove is more appropriate if due to the geological characteristics to make the pile foundation is impossible.

Prefabricated foundations for this type of materials are not recommended. Most of the challenges arise with housekeeping houses on foundations from FBS, building blocks or bricks. Due to the fact that they themselves have a tendency to form cracks, in tandem with cellular concrete it turns into a serious problem: too much cracks often arise. Because the national foundations do not use.

And we pay attention to, answer with a 100% guarantee what the foundation for the house of a housekeeping can only be the designer with the results of geological research on the site.

Aerated concrete is easily processed, which allows you to build houses of complex configuration

With chokol or without

Another feature of aerated concrete is high hygroscopicity. With increasing humidity, it loses its heat insulating properties, and long-term destruction in water can lead to partial destruction of the material. Therefore, the house of aerated concrete is mandatory on the base, making several layers of cut-off waterproofing. And this is in addition to all measures for the waterproofing of the foundation, which are also determined by geology and groundwater levels.Aerated concrete house: block laying

All begins with the preparatory activities:

- Check horizontal foundation. If there are deviations more than 30 mm from need to be eliminated. If there are small humps, they are easier to cut, and the pit is filled with mortar. If the surface is too uneven, an additional formwork is installed, the surface is filled with concrete and levels into the level. Just keep in mind that the minimum thickness of the concrete layer is at least 3 cm, and for alignment you need or add plasticizers that improve spreading, or treat a solution with a vibrator for concrete. Works can continue when concrete will drop 50% strength, and this is 7-9 days at a temperature of + 20 ° C, and 14-20 days at lower.

- The shut-off waterproofing is stacked. First, rolled waterproofing is obsessed with bitumen mastic. And it is better not runneroid. It certainly is cheap, but in modern performance is ineffective and very short-lived. When sticking tapes, one on another enters at least 15 cm.

At the preparatory stage, it is necessary for everything with the maximum zeal. The smaller will be the base, the easier it will go. The importance of waterproofing has already written about the importance: you want a house of aerated concrete to be a warm - take care that it is dry.

Rules for laying aerated concrete blocks

On top of the shut-off waterproofing, you can begin the masonry of the aerated concrete. It is conducted on the same rules that brick: with horizontal bandage of rows. This means that the vertical seam of the lower block overlaps the body of the block lying on top. It looks more beautiful, if the seam is in the middle of the block, but the minimum indent is 10 cm.

Article on the topic: Schemes Embroidery Cross Children Children: How to teach to embroider for free, kids download, topics and video, motifs

Principle of laying blocks from aerated concrete

Special glue is used for masonry gasoblocks. It is called - for aerated concrete. It is applied with a thin layer of 1-2 mm using a special tool - carriages with a toothed edge. Why preferably put this layer? First, glue dear, secondly, it is a cold bridge, as it has thermal conductivity much higher than that of the gas block. Therefore, the specified thickness is optimal: it provides a solid docking and minimal heat loss.

Tool

For uniform laying of glue, there are branded carriages. They are a box that is loaded to a bucket of the solution. Laying of aerated concrete blocks with their own hands using the carriage is shown in the following video.

To carry her on the walls up and down the pleasure of doubtful and justified only with large volumes when all the bucket can be rolled through the wall at a time. Therefore, during the independent construction of a gas-concrete house, the devices are more often used - small hand carriages (see photos). As you can see, it looks like a scoop and it is easy to make it with their own hands from a piece of galvanized. The width is equal to the width of your block (just up to a millimeter, it is possible for 1-2 mm less). On the edge of the cloves (can be chopped), a handle has been attached. In principle, you can do the tricks and a big gear spatula, but it will not work so convenient.

The second necessary tool - saw. It also has a special, but foam concrete perfectly cuts out the usual hand saw with a well sharpened tooth.

Carriage and saw - Basic tools

You still need a device for grade. According to the construction technology from aerated concrete, the reinforcement is stacked at each 4th row. Under these rods are made in the body of the block of the plot. To do this, there is a special tool - the cutting edge on the handle with an emphasis for the second hand. It is also possible to make something like this.

Two models of stroke-cutting for gas block

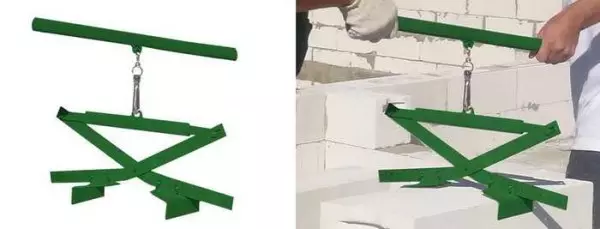

Also necessary devices for transferring blocks. There are blocks with cutouts under the hands, but they are more expensive, and emptiness will then have to be chopped with a solution. To transfer blocks with even edges there are special ticks working at the expense of gravity.

Block transfer device

In addition to all this, a container for kneading glue, a raner bucket, a milestone - align blocks, a brush - to count dust, construction level, cord, a set of skins or a special grater - for aligning surfaces. That's all the necessary tool. There is another interesting fixture - an angle that allows you to cut at right angles. In the photo it is near the helmets, but if desired, without it you can do.

A set of tools required when building a house of aerated concrete

Laying a fuel-concrete block

Aerated concrete laying technology is simple: a more or less smooth layer is applied to the lower surface. Recommended layer thickness 1-2 mm. With this application with the help of a carriage of excess glue, it does not happen, and is rarely squeezed. Also applied to the side surface of the block located nearby. You can do this with the help of a peel, spatula, or immediately a carriage. Surplus are also removed to the toothed side of the instrument. Applying glue, try so that it does not flow from the edge of the block: it is hard to remove it with a white surface.

How to apply adhesive under aerated concrete

All the above belonged to the masonry on special glue. Some in order to save the cement-sandy solution. His thin layer is not posted, because there will be surplus. They are removed by the edge of the tool, but the laying still looks untidy. About the heat engineering parameters of such a wall is generally better not to say: cold bridges are very broad.

Before installing the unit is deemed: take the brush and exercise along all surfaces. If the weather is dry and hot, the block is sprayed with water. You can delay a wide brush, you can - from the pulverizer. The purified and moistened block is raised and put on glue, close to the already installed. Using the image, knocking on the pure side surface of the installed block, achieve the required seam thickness of 1.5-3 mm. Expandable glue surplus are removed by a spatula.

Installing block

Now take the level, and flatter the block in the vertical and horizontal surface: knocking at the corresponding places in Cyan. Efforts may need serious. Calculated glue, if we are selected.

Align the block in all planes

Such an operation is repeated once over time. Non-flat, but monotonous work. But to build a house from aerated concrete with your own hands without any construction skills. The main thing is to comply with technology.

Useful devices and useful refinement of laying technology in the following video. People with their own hands build a house of aerated concrete for themselves, everyone makes quality, but quickly using interesting devices. The solution is applied using a modified toothed spatula. From the sides are small plates on it, they do not die with a solution beyond the block. The design is obtained in the form of the letter "P", but with short "legs" and a wide "back", from the middle sticks out the handle of the spatula.

The design is put on the block, the glue is thrown along the wide side. Beyond the edges or for the handle pull along the block. At the same time, glue squeezed out of the teeth. It is immediately distributed evenly. With the help of the same fixture, glue on the side, but not installed, and the installed block. Stacking speed with this method is high.

Article on the topic: How to pick up curtains on panoramic windows in an apartment and house

It is very interesting to carry the unit to transfer. This is a metal plank with two welded handles. It, of course, every time it is screwed into two screws to the block, but to transfer more convenient than just holding the edges. In general, a useful video, only align the blocks "to the eye." This "reception" is unlikely to take into service, and in the rest way to masonry the blocks of aerated concrete in the video is very good.

Masonry of the first row of aerated concrete

With any construction, it is very important to correctly set the first row: then we will be focused on the construction of walls. Therefore, we do it very carefully, rechecking several times. The first row of aerated concrete blocks put on the cement-sandy solution, all the others - for glue. Attention! The side surface is deceived by glue: these seams should be normal - no more than 1-2 mm.

The first is the angular blocks. Very often, their outer edge acts beyond the base. Firstly, the base will then be insulated and separated, and this will significantly increase its thickness. Wall hanging over the basement - not only looks more organically, it also reduces the calf of the base, and first of all its junction with the wall, and for a fuel-concrete house it is very important.

First of all, with the help of a laser builder of planes or water levels, we find the highest corner of the base. From him we start laying. The entire meaning of the first row is varying the thickness of the solution, align the blocks in the horizontal plane. At the preparation stage, the greatest differences were eliminated, but the surface still hardly became perfect. In order to lay the aerated concrete blocks in the future, it is easier and levels the surface.

How to find the highest corner of the foundation Look in the video.

Therefore, at the highest corner of the solution, put the minimum quantity. We lay out a layer of 0.5-1 cm, spread. We put the first block so that its outer edges performed at least 50 cm beyond the base. As they wrote, this protrusion is not necessary, but it solves many problems, and most importantly, it closes the joint with the basement.

I exhibit the first block, knocking in the image, aligning

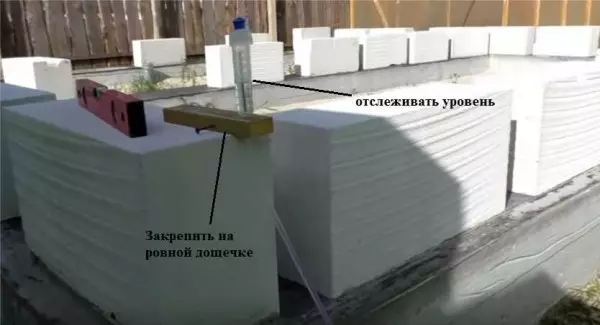

We take the level and, tapping in the image, align it in horizontal and vertical planes. On the adjacent angle, we do the same operation, only the height of the block is adjusted by the first and for this we use the water level. To work it was more convenient, the levels of the level can be fixed on smooth plates of the same thickness. By setting one flask on one corner block, the second one can adjust the height of the other.

Comfortable device

We repeat the same operation on the other blocks. One subtlety: tolerate the level only from the first block. So the error will be less. After all the angular blocks are exhibited (they are called beacons), the cord is tensioned by their outer edge. Moreover, the cord marks the upper edge of the block and all the others are aligned. Tighten the screws into the screw to the block: it is spinning easily, and it keeps well. You can screw to the blocks of the plank, in which the screws are screwed.

On the side of the two strips, which are already fixed with a lace to beat the row level

The laying is desirable to lead from two angles, moving in the middle. So more chances to avoid distortions, which then you have to align, breaking the already installed blocks.

Second and subsequent ranks

Upon completion of the styling of the row take sandpaper, the planer, the construction level and pass throughout the perimeter, removing too large height differences. This is an important point that allows you to spend the minimum of glue. But the minimum seam is not all. If not to level the height of each row, the places of local stresses are formed in the wall, which, with minimal loads, can cause cracks. Therefore, do not skip this stage.

Work essay is not very convenient, there is a special grater for these purposes. She is not so clogged. So, everything is leveling in level. Then they take the brush and pass again around the perimeter, the estimated dust. This stage is also impossible to miss: the presence of dust significantly reduces adhesion of glue with blocks.

Height difference is checked to the touch))

All this in order to withstand the recommended layer of glue in 1-2 mm. Geometry of even the most good blocks still has a run. Let the difference be 1 mm, but with such an amount of glue it is significant. Therefore, everything is aligned until complete coincidence.

The hired brigades often miss this stage and glue glue to 5 mm and more in violation of the technical process. But such houses are cold, and the consumption of expensive glue is huge. On average glue consumption per cube:

- Smooth blocks - 1.2 bag;

- With groove and ridge - 1 bag.

Laying the second and subsequent rows of aerated concrete blocks also begins with an angle, only an angular block is exhibited so that the seam is shifted. Now glue composition is applied to all surfaces. The laying technology of the gas-concrete block is described above.

Article on the topic: Wood-chipstop for walls represents a budget finish option

How to lay out an angular block of the second row

Reinforcement of aerated concrete

In order to increase the degree of resistance to the building to the efforts arising from the beading of the soil, a longitudinal reinforcement of walls is produced. To do this, in the laid blocks with a special device, the longitudinal grooves are strobalized. For thick outer, two grooves are made under two rods, for jumpers with a thickness of up to 200 mm lay one thread. From the edge of the block, they should be at a distance of at least 6 cm. When two grooves are more convenient to withstand the distance, putting the board: one shit - on the one hand, the second one - on the other.

When the grooves are ready, dust swept the brush of them. Then they take the reinforcement of 8 mm, pre-lay out in the prepared shoes. You are delivering so that whole rods lay in the corners: they simply bend them in the right place. The joints of the reinforcement should have about the middle of the block, but not in the corners of the building and not in the places of the walls of the walls.

One bar is imposed on the other, laying nearby. The overheet must be 10-20 cm. In order to in the places of openings (door and window), the ends of the Armaturin are not sticking out, small pieces can be beatened by making small shoes under them.

Reinforcement of angles and adjoins make a solid rod

When everything is decomposed, we take the rods, wet the stroke with water and half fill with glue or concrete solution. And it is necessary to clean and wet necessarily, otherwise the solution does not fit with the material of the block and there will be no sense from reinforcement. The glue blends the rods, then we pass the spatula along the grooves, removing the surplus and leveling the layer.

Such reinforcement is carried out in the first row, and then - in every fourth. With regular dressing, even with an uneven sediment of the foundation, a house of aerated concrete will stand normally.

But it is not all reinforcement. Over the window and door block, as well as in the last row of the floor, the elements of amplification are required, but already more serious, with 4 rods associated with a single system. For this there are special U-shaped blocks. They are put as the last row under the overlap of the second floor or under Maurylala roofing. One side wall at the bloc thick, the second is thinner. The thick wall is unfolded and the street, thin - to the room.

An example of a device of the reinforcing belt during the construction of a house of foam blocks

Of the 4 rods of the reinforcement with a diameter of 10-12 mm, a continuous reinforcing belt fit. It is knitted by the same principle as in the belt foundation (you can read here). An example of a reinforcing frame - in video.

The finished elements are stacked into the cavity of the unit, fill with the M200 brand concrete. After a set of concrete, 50% of the strength can be labeled or put the lines of the roof.

Reinforcement of window openings of aerated concrete houses

According to the technology, if the house of aerated concrete has a window door wider than 1.8 meters, the penultimate row of gas blocks is additionally reinforced. For this, there are two longitudinal shoes, which, at least, 0.5 m longer window opening. To reinsure, you can make the protrusions more - up to 1 meter, and reinforce under each window opening.The technology is similar to the wall: two shoes in which the rod is placed, it will be filled with glue or solution. On top of the reinforcement, the last number of blocks is set, and it is later a window frame.

General principles of work with foam concrete blocks are described in the following video, the principles of reinforcing window and doorways are also highlighted.

About the features of wall decoration from aerated concrete here.

How to get over without heating

Often to build a house of aerated concrete in one season does not work, as a result, the box is under the roof or without - goes in winter without heating. So after wintering in the walls, there are no cracks, a whole range of events is needed:

- If the groundwater is high, before the onset of cold weather, it is necessary to make a drainage system.

- Waterproofing and outer insulation of the foundation and base (for the average EPPS strip with a thickness of at least 100 mm).

- Insulated cesspool around the house.

- Floor insulation in the basement.

All these events are designed to prevent the freezing of the soil under the foundation and, in particular, under the basement floors. If the soil under the stove freezes, it will begin to write in the most unloaded place - in the middle. If the brick and other heavier materials simply give the release, then the massicate of the mass is missing. Therefore, all measures listed above are mandatory.

What can be seen after freezing

In addition to them in frosts, it is necessary to maintain a plus temperature in the basement - at least a couple of bourgeokes to stir. If you organize the heating there is no possibility, it is necessary to load in the basement fairy folia from the autumn. The layer is preferably large - at least 20 cm. In a bundle with thermal insulation, it will not let it freeze the slab. Otherwise, it will still be released, as a result of the walls crackle - with loads on the gap, the gas silicate wall gives cracks not under the seams, like a brick, but according to the "body" of the block. It looks frightening, although with a normal foundation (if it remained whole) everything is not so scary and when heating in all the next seasons it may not happen.