Often, in the repair process, it is necessary to put partitions, and more and more often, aerated concrete (gas-silicate) is used for this. It is light - at times less weighs than brick, the walls fold quickly. Therefore, partitions from aerated concrete put in apartments and houses, regardless of what carrier walls are made.

The thickness of the partitions from aerated concrete

For the construction of partitions indoors, special gas-silicate blocks having a smaller thickness are produced. Standard thickness of partition blocks 100-150 mm. You can find non-standard 75 mm and 175 mm. Width and height remain standard:

- width 600 mm and 625 mm;

- Height 200 mm, 250 mm, 300 mm.

The brand of aerated concrete blocks should be not lower than D 400. This is the minimum density that can be used to build partitions up to 3 meters high. Optimal - D500. You can also take and more dense - brands D 600, but their cost will be higher, but they have a better carrying capacity: it will be possible to hang out items on the wall using special anchors.

Without experience, the brand of aerated concrete is practically impossible to determine. You can see the difference between thermal insulating blocks the density. D300 and wall D600, but it's difficult to catch between 500 and 600.

The smaller the density, the larger the "bubbles"

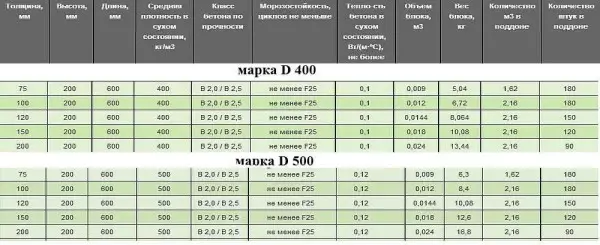

The only available method of control is weighing. Data in size, volume and mass of partitioned blocks from aerated concrete is shown in the table.

Parameters of the blocks of aerated concrete for partitions

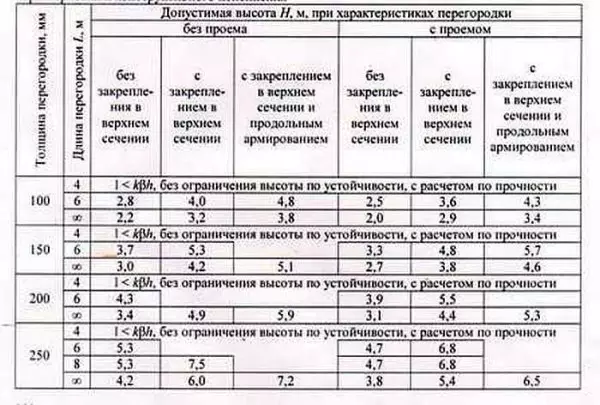

The thickness of the aerated concrete partitions is selected by several factors. The first is a carrier of this wall or not. If the bearing wall is, in a good, requires the calculation of the bearing capacity. In real life they make the same width as the outer bearing walls. Basically - from the wall blocks of 200 mm widths with reinforcement, like the outer walls. If the partition is not carrier, use the second parameter: height.

- At an altitude of up to 3 meters, blocks 100 mm wide;

- From 3 m to 5 m - the thickness of the block is already taken 200 mm.

More precisely, select the thickness of the block on the table. It takes into account such factors as the presence of pairing with the upper overlap and long partition.

Article on the topic: How to soline a shower cabin?

Choosing the thickness of partitions from aerated concrete blocks

Device and features

If the aerated concrete partitions put in the repair and redevelopment of apartments or houses, you must first put markup. The line is surrounded throughout the perimeter: on the floor, ceiling, walls. The easiest way to do is having a laser plane builder. If it is not, it is better to start with a stream:- The ceiling is marked with a line (two points on opposite walls). Between them stretch the paint cord painted with blue or other painting dry substance. With it, beat off line.

- Lines on the ceiling with a plumbing to the floor.

- Then the lines on the floor and the ceiling are connected, spending verticals on the walls. If everything is done correctly, they must be strictly vertical.

The next step of construction of a partition from aerated concrete - waterproofing of the base. The floor is cleaned of garbage and dust, laid waterproofing rolled material (any: film, rubberoid, waterproof, etc.) or wipe the bitumen mastic.

Vibrating strips

To reduce the possibility of the formation of trees and increase the soundproofing characteristics, the vibrational strip is spread from above. These are materials with a variety of small air bubbles:

- rigid mineral wool - mineral cardboard;

- high density polystyrene foam, but small thickness;

- Soft fiberboard.

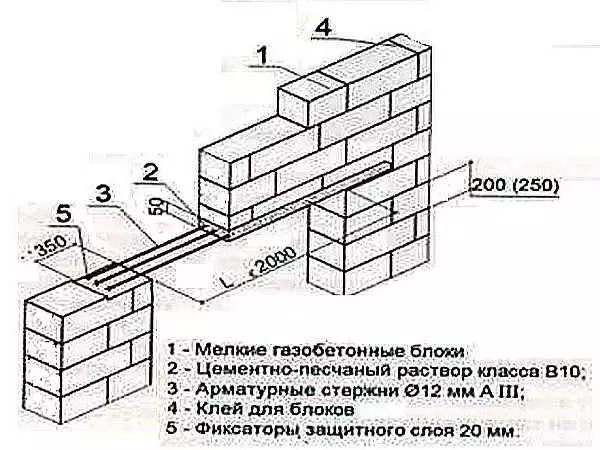

The first row of blocks is stacked on this lane. The thickness of the glue is 2-5 mm, the consumption with a thickness of 1 mm 30 kg / m3. Next, the construction of partitions occurs on the same technology as bearing walls. Read more about Wall laying technology from aerated concrete.

On short spans - up to 3 meters - reinforcement do not do at all. For longer, the reinforcing polymer mesh, perforated metal strip, as in the photo, and the like.

Partitions made of aerated concrete, if desired, you can reinforce

Adjoint to the wall

To communicate with the adjacent walls at the laying stage in the seams, flexible bonds are laid - these are thin metal perforated plates or T-shaped anchors. They are installed in every 3rd row.

The connection of the walls and partitions with the T-shaped anchor

If the partition from the gas silicate is put on a building where such bonds are not provided, they can be fixed on the wall, bent in the form of the letter "G", starting one part in the seam.

Article on the topic: Crocheted Curtains: Step-by-step instructions and schemes

When using anchors, the connection with the wall is rigid, which in this case is not very good: the hard rod from vibrations (wind, for example) can destroy the adjacent glue and body block. As a result of the strength of the adjoining will be zero. When using flexible links, all these phenomena will not so much to influence blocks. As a result, the strength of the connection will be higher.

Flexible ties in the seams, if there are no, the plates are simply screwed into the screws

To prevent the formation of cracks in the corners, between the wall and partition, they make damper seams. It can be a thin foam, mineral wool, a special damper tape, which is used when laying a warm floor and other materials. To eliminate the "SUPPLY" of moisture through these seams, they are treated by paro after masonry not permeable sealant.

Operactions in gas-silicate partitions

Since the partitions are not bearing, the load on them will not be transmitted. Therefore, over the door there is no need to lay standard reinforced concrete beams or to make a full jumper, as in the bearing walls. For a standard doorway in 60-80 cm, you can lay two corners that will serve as a support for overlying blocks. Another thing is that the corner should appear by 30-50 cm. If we are wider, you need to need a channel.

On the photo to enhance the opening of the standard door, two metal corners are used (right), in the opening, the channel is closed, under which the grooves in blocks are selected.

If we open the uninforcement, and the block is joined in it only two, it is desirable to pick them up so that the seam is almost in the middle of the opening. So you will get a more stable opening. Although, when laying on corners or channel, this is not the table. It is important: the bearing ability is more than enough.

Door openings in aerated concrete partitions

In order for the metal to dry the glue, do not fade, the openings are enhanced. In embarrassing openings, it is enough to navigate the boards, it may take a supporting design that rests on the floor (folded the column from blocks under the middle of the opening).

Another option of how to enhance the door opening in a partition from aerated concrete is to make a reinforced ribbon from reinforcement and glue / mortar. In the opening strictly horizontally pinch a flat board, navigating it with nails to the walls. Bocames are nourished / screw the sidewalls that will hold the solution.

Article on the topic: Cuttings Chinese: Exceptional features and subtleties

A solution is stacked on the board from above, it is three rods of class A-III valves with a diameter of 12 mm. On top there are partition blocks, as usual, following the displacement of the seams. Remove the formwork in 3-4 days when the cement "grab".

Opening in the partition from blocks

Last row - kneading to the ceiling

Since during the loads of the ceiling slab can be fed, the height of the partition is calculated so that it does not reach the overlap by 20 mm. If necessary, the blocks of the upper row are saw. The resulting compensation gap can be seen by damper material: the same mineral cardboard, for example. With this option, the sounds from the top floor will be heard. The easier option is to moisten the seam with water and pour it with the mounting foam.Soundproofing aerated concrete

Although the sellers of gas silicate blocks and talk about high sound insulation, they greatly exaggerate. Even a standard block of 200 mm thick is well spent sounds and noises, and more thin partition blocks and suppressed.

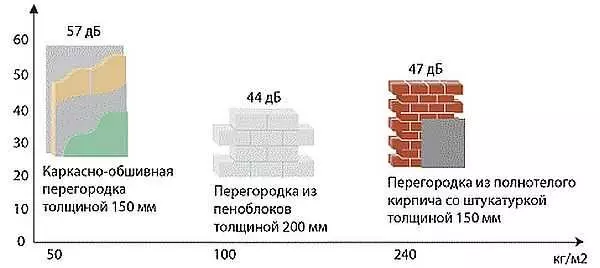

Comparative characteristics for soundproofing partitions from different materials

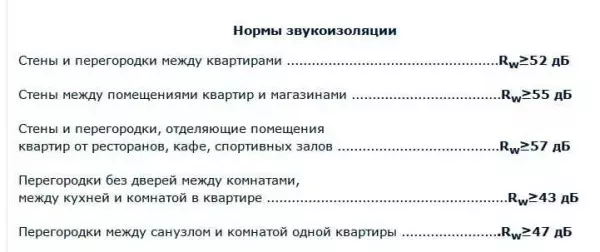

According to the standards, the sound resistance of partitions should not be below 43 dB, and better if it is above 50 dB. This will provide you with silence.

Soundproofing standards for different rooms

To have an idea how "noisy" gas-silicate blocks, we give a table with normative indicators of sound resistance of blocks of different density and different thickness.

The sound absorption coefficient of aerated concrete blocks

As you can see the block, 100 mm thick it does not reach the lowest requirement. Therefore, when finishing aerated concrete, you can increase the thickness of the finishing layer to "reach" to the standard. If the normal sound insulation is required, the walls are additionally squeezed with mineral wool. This material is not sound insulation, but approximately 50% reduces noise. As a result, the sounds are almost not heard. The best indicators have specialized sound insulation materials, but choosing them, you need to look, the characteristics of vapor permeability, so as not to lock the moisture inside the gas-silicate.

If you need absolutely "quiet" walls, experts advise two thin partitions with a distance of 60-90 mm, which is filled with sound-absorbing material.