Of the 20th century, a lot of interesting building materials came, but the profiled timber is distinguished among others. It is not only special because of its appearance, but also due to the specifics of the consistent vertical connection. However, the angular connection of the profiled bar is much more complicated, because It is necessary to achieve ideal strength indicators.

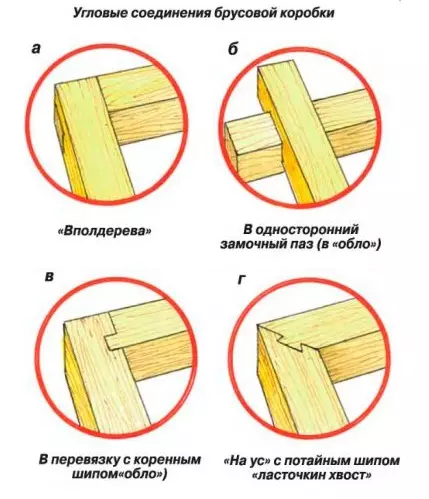

The corner connection of the bar can be carried out in various ways, all of them are durable compounds.

Process study

There are many options to make a joint, and the situation depends not only on the desired angle, but also from the personal preferences of the wizard. When choosing a method of junction 2 of the master in 9 cases out of 10, it will be divided into opinions, but both will be 100% right, because Most ways are interchangeable.

The most popular option is a quaternary groove. For its implementation, you will need to do:

Types of corner connections of timber.

- On any selected section of the bar, except for the end, 2 marks are set, the distance between which is equal to the width of the bar. At the end, such marks can not be put, because The joke will be unreliable.

- In the marked place, the pencil is formed a rectangle to a height of 14 timber, and a similar one is drawn.

- A cut of the marked sectors is performed.

As a result, 12 from the base thickness in this area remains, thanks to which the bars can be folded without fears. This option was borrowed from the round, but there he is known as a joint in the Russian bowl.

For angles, it is fairly convenient to use the pairing trapezoid castle. This compound method was originally called "in the paw", but the design was improved to ensure greater reliability of the joint. Here the work is done much more complicated, because It will be necessary to use 2 types of cutting:

- An indentation of the edge is made equal to the width of the timber, after which only 13 is left in the center, and at the end expansion up to 23. Thus, an improvised trapezium with an extension at the end is obtained.

- The trapezium expands not by the end, but from 1 side to another. The ratio should be saved perfectly.

Article on the topic: Homemade concrete mixers: manual, electric

With a consistent perpendicular addition, you can get a perfectly smooth vertical at the output. Sometimes a little exceeds the indent, which will not play a significant role, and after the installation is completed, it will be necessary to simply remove the electrourub or circular.

With the mass work, the simplest spike-groove technology is used. For the corner connection of the profiled bar, this option is firmly suitable, if desired, it is fairly easily adapted:

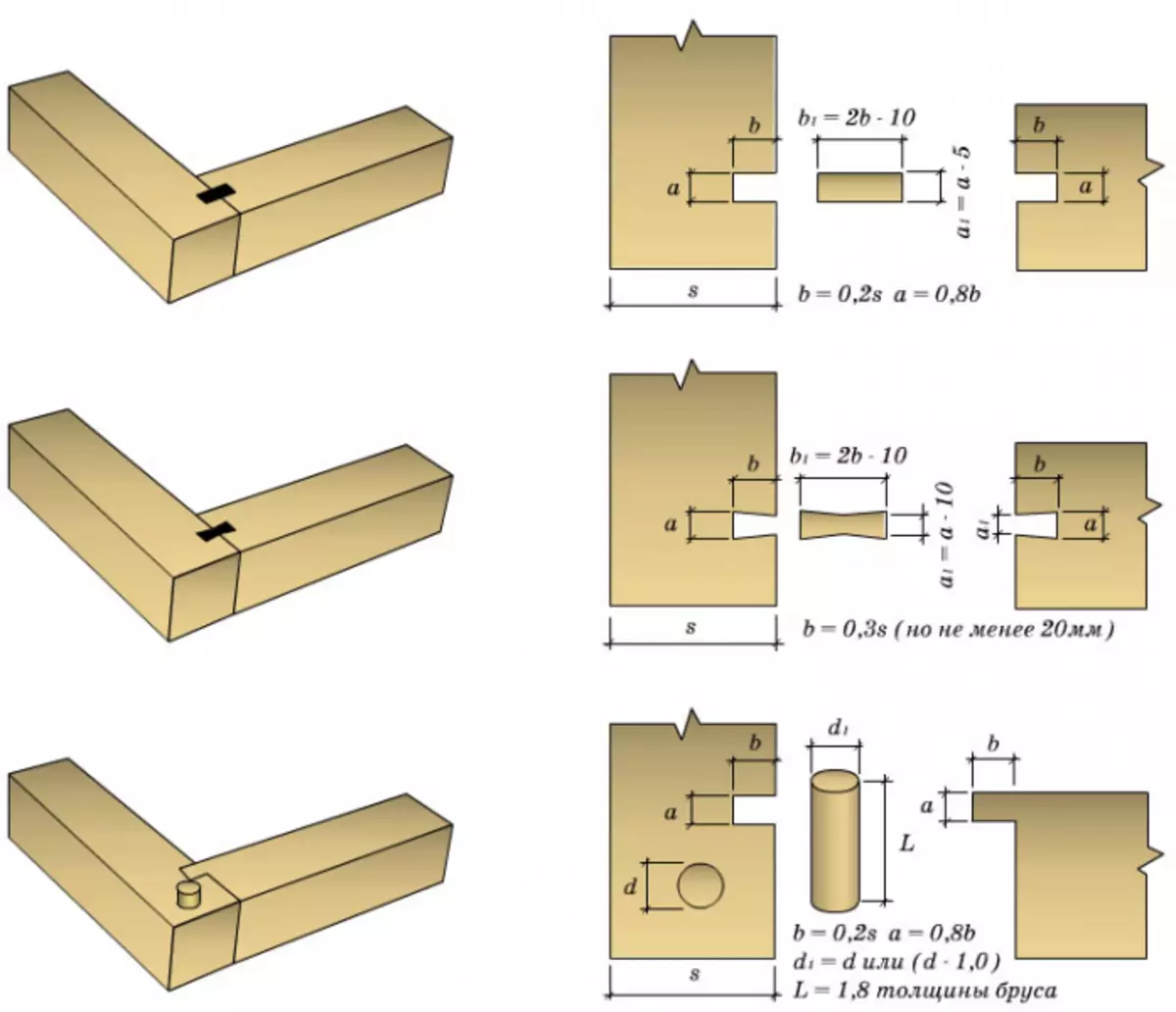

Types of corner joints cut from a bar.

- The rectangular groove is cut into a depth of 5 cm. When cutting out this groove, you will have to use a small diameter chainsaw, because The base will still have a slight expansion. The gap will be already, the better.

- From a perpendicular bar is cut off all too much to leave the appropriate spike. Reducing the length of 5 km is slightly, so it's not worth thinking about it.

- Compound 2 elements.

- If the situation of that requires, the guide furrows right with Raspil (manual process profiling).

Thanks to the last option, many more methods that use the "swallow tail" technology appeared (it is also compounded by a frying room) and the groove system. Each of these technologies has its own characteristics that allow you to organize an angular connection of the profile bar.

The compound of frying and semi-fertility differs only by the share of reliability and complexity of manufacture. Usually the complete option is used, but when connections with an acute or blunt angle, the half-option will be perfect due to its simple adaptability. The connection with a solid service allows working activities very quickly, but it is difficult to prepare for it.

Schemes of bruse joints spike.

But work with grooves allows you to form angular joints with no less speed, but reliability will be chrome. The "Native Schip" version is very similar to a quaternary groove, and here it is not necessary to make such deep grooves, but it is impossible to use joints on each row, which is why each 2 bar is depending on it.

Article on the topic: How to finish the doors with MDF panels do it yourself

Plug-in spike is much more interesting in detailed consideration, because The drawn version is quite primitive. This method of the joint will keep the walls even with an average lateral pressure, but it is not necessary to hope for very high reliability.

Sometimes the spike is used in combination with other variations of vertical junctions, for which, after installation, the vertical hole is made, where the round rack is driven. This rail will serve as an additional clamp.

Used tools and summing up

When working, a large set of tools and materials will be required:

Schemes for connecting a bar "in Polterev" and "in paw".

- roulette;

- Pencil simple;

- Circular;

- chainsaw;

- rasp;

- Bar profiled;

- drill;

- milling machine.

Use all tools is not at the same time, and it will not work. The choice is done depending on the complexity of the work, i.e. For the finest, the chainsaw is also suitable for a coarse and circular, while the hand milling machine will be used only to form the simplest grooves.

To connect 2 bars with your own hands, it is not always necessary to carefully select the option, because Most of them are interchangeable. It is very important to relate to the compounds at the ends, because Their design is quite complicated, because of what can leave a little longer than planned.

And in cases where you need to cut a lot of wood, it will be better to make a template from sheet steel, which will be perfect to meet the work done.