The furnace or fireplace in the house is becoming a key element of the decor and

Contribute to creating a feeling of heat and comfort in the house. Chimney facing tile

Allows you to create different finishes and organically enter the furnace in

The interior performed in any style, from the classics to High-Tek.

But so that the beauty created does not destroy as long as possible,

It is important to choose the proper facing material and the scene for the furnace tile.

Choosing a mixture, you should consider the special operating conditions of the furnace or fireplace

(The surface is very heated). And therefore not only tile, but also glue,

which fixes it must have special fixing properties.

What solution to put the tile on the oven? This is the question

Which first will interest the owner who decided to make a facing of the oven

do it yourself.

Solutions and mixes for facing stoves tiles

Building market offers many compositions for plating

Heating surfaces. But, you can highlight three fundamentally approaches to

obtaining a solution with additional options.

1.Recery for facing the oven tile of manual kneading

Advantage of self-made solution from components:Ecology, low cost, good reviews, checking time. Disadvantages:

The complexity of compliance with proportions, corruption and temporary training costs.

However, most of the masters of tilers and liveshchers

advise the use of a "natural" solution for facing the furnace and

They offer several of their varieties.

1.1 Clay Solution for Furnace Facing Tile

The clay solution for facing the oven tilt designed to lay tiles and ceramic tiles.

Immediately focus on the fact that the clay solution,

consisting of clay, water and fillers, is used for masonry furnaces, and for

Tile cladding - very rarely. This is due to the fact that high temperature

Reports clay such property as durability. Which in turn affects

The ability of cladding to play under the influence of temperature and leads to it

cracking.

Levels such a property of clay are called fillers, in

The quality of which can be sand, sawdust, sep, wood chips.

The most effective filler is a sinking river sand.

The composition of the clay solution

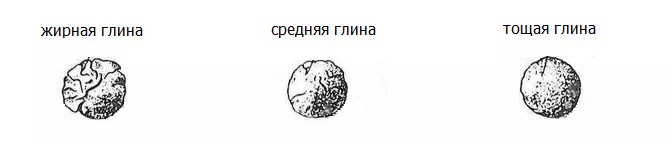

The composition of the solution depends on the fat content of clay.Fatty clay coefficient: with minimal (no more than 15%) of sand in clay,

It is considered fat. If the sand content is in the range of 15-25% -

Normal, more than 25%-skinny.

How to determine the fatty clay

Determine the type of clay can be without laboratory checks

in several ways:

- wipe clay with your fingers, in fat - the sand is not

Feels.

- Skick it into the ball, slightly attach and dry.

The cracking of the ball will indicate that the clay is fat and

On the contrary, if the ball will take care of his form - clay skinny.

Item definition clay - balls

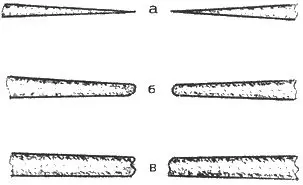

- It is good to stretch clay and roll out a thick sausage from it

20-30 mm. Then gradually stretch it, watching the behavior of the mass. On the

The figure shows how fat (a) behaves, normal (b) and skinny (c) clay.

Accordingly, the quality of clay affects the proportions of the solution

For facing the furnace.

The proportions of the clay solution

With oily clay, the ratio of clay to the filler will beMake 1: 4, for normal 1: 3, for the skin 1: 2.5.

The general rule is the less clay content, the higher

The ability of the solution to withstand high temperatures without cracking.

However, the more sand, the less the adhesive ability of the solution. therefore

It is important to withstand the golden middle and clearly adhere to the recommendations.

How to make a solution for tile on the oven without experience of furnace work?

Professionals advise reception: add salt into a clay solution.

1 cup support salt on 1 bucket of finished clay solution. Salt attaches

The solution is the ability to retain moisture and not crack. You can also

shampe powder into the solution, it will give a solution to the ability to withstand

High temperature. Especially relevant this recommendation for those who drown

The furnace is not wood, but coal.

Water is added in the proportion of 25% of the clay volume. The readiness of the solution is determined by its plasticity.

Consistency of the clay solution in the photo below:

1. Dry clay solution - add water;

2. Liquid - add clays;

3. Normal.

Dry clay solution

Liquid clay solution

Normal clay solution

How to properly disperse a solution from clay?

The mixing of the clay solution is performed by legs ortrowel. Invalid use of a mixer, because he whips clay and reduces

The quality of the solution.

Council. Preliminary soaking clay by 1-1.5 days

Make the kneading solution easier.

How to make a solution from clay - video

1.2 cement-clay mortar for masonry

Or clay-cement-sandy solution.To give a clay solution to the strength in it

Add cement and chalk.

The proportions of the cement-clay solution (1: 1: 1: 3)

- 1 part of cement

- 1 part of clay

- 1 part of the chalk

- 3 pieces of sand

Such a solution will have increased adhesion with

Surface. A feature of the mixture is that it is prepared in a dry form. Cement

Stirred with sand and chalk. Then in this dry mixture is added clay

Pulp, which is a clay, diluted with water.

After bringing the mixture to the desired consistency in it

Add one piece of liquid glass. Such a solution is used for cladding

surfaces of severe larger tile or tiles on ready-made

surface.

For gluing ceramic tile standard sizes

The masters recommend using a solution with a simpler composition:

- 1 part of clay

- 1 part of cement

- 3 pieces of sand

- 1 glass of salt

1.3 lime mortar

The mixture consists of 1 part of the extended lime and 3 parts of the sand.Lack of lime mortar - when used in

The room, the increased humidity remains for a long time. Today lime

Replaced cement. Judging by the reviews, many advise not to use a solution on

the basis of lime for facing the oven tile, and if the old coating was

Lime, it is better to remove it (knock down) to eliminate the probability of detachment

new coating.

1.4 Cement mortar for styling tiles on the furnace

Cement mortar for facing furnace Tilt-cement solution is suitable for laying tiles on horizontal bases. The cement solution after drying is gaining less strength, rather than clay, and therefore suitable for facing the base tiles subjected to periodic loads. In addition, in this case there are no special requirements for the fixing properties of the solution, as in the case of cladding vertical surfaces.

The composition of the cement mortar (1: 3)

1 part of cement on 3 pieces of sand.

A solution is mixed using a mixer or a special drill nozzle.

Getting Stoves Furnace Tile using

cement solution must be remembered that the solution quickly "seats" that

Requires constant mixing it.

Council. Adding a washing powder into a cement solution in

ratio of 100 gr. On the bucket of the mixture - to lean the solution.

Note. Laying natural stone or mosaic on

Cement mortar will affect the appearance of the lined furnace surface,

Therefore, it is better to use glue solutions based on white cement.

So that the facing well kept on the surface of the oven

Perform the following recommendations:

Futter Furnace Furnace Chamotted Bricks First, it is better to choose that lining solution to which the furnace was masonry.

Secondly, the lining of the furnace furnace chamotted brick will allow

reduce surface temperature and thus reduce the requirements for glue

solvent. For lining applies refractory chamotte brick, which

stacked in the furnace part (see photo) and creates a barrier for high

Temperatures.

Material prepared for site www.moydomik.net

2. Previous dry mix for facing stoves tiles

Professional firing and amateur masters in mostIts preference not to prepare solutions with your own hands, but

using ready-made mixtures. Fortunately, choose in the construction market there are from

what.

Choosing a dry mix for facing the oven tile you need to know

That universal glue is not suitable for this. Solution for laying tiles on

The furnace must have special properties:

- high temperature resistance . For packaging required

Marking "heat-resistant" or "for facing stoves and

fireplaces. " If the temperature of using glue exceeds 200 ° C it can

use for furnaces and fireplaces;

- Elasticity of glue . Gives adhesive composition

withstand temperature differences;

- The surface for which glue is designed . All surfaces

They are divided into two types. Simple surfaces - deformation resistant (concrete,

Brick, cement screed). Complex surfaces - non-stable deformation

(for example, plasterboard, metal, wood, MDF);

- tile for which glue is designed . For example,

Terracotta tile or porcelain stoneware needed a special adhesive

composition;

- Coupling with the surface and the force of fixation . Primer,

applied to the base allows you to increase these properties of glue;

- Hardening period . Important if you need to perform work

urgently. Varies within 1-7 days;

- The period of using a mixed solution . Glue for the furnace

Tiles have a slight time to use after kneading that

Increases the speed of work. It creates difficulties for laying tiles

newcomers and leads to the fact that a significant part of the finished solution goes into

Waste. The shelf life of the finished solution is 20 minutes - 1 hour for laying and

5-15 min. On the adjustment of the tile.

- Packing glue . Dry glue solutions are sold in bags

25 kg. The shelf life of the open bag is limited, which is due to its

ability to absorb moisture, so it is better to use with a minor work

Packing at 10 and 5 kg.

Preparing the solution to use is very simple and

It lies in the positiveness of the solution with water in the desired proportion in a clean capacity.

To increase the plasticity of the mixture, you can add PVA glue at the rate of 250 ml. on the

10 liters Solid. Kneading is performed using a building mixer that

Allows avoiding lumps. Foaming of the solution is not allowed (you need

adjust the speed of rotation of the drill-nozzle).

Facing Glue Stoves Tile - Manufacturers

Among professionals and ordinary users popular

Enjoy Marie (brands):

Ceresit CM 16Ceresit CM 16 Elastic glue for Flex tiles (Ukraine, German license, 600 rubles / pack.). Cerezite Flex is designed for laying on

Complex deformable bases, as well as tile by tile.

Glue "Terracot" glue heat-resistant reinforced "terracot" (Russia, 550

rubles / pack.). Used for cladding with natural stone and ceramic tiles

Terracotta. Chamoite kaolin dust, added to the composition of the adhesive solution,

allows you to make a lining without a lining furnace and get identical

result. Operating temperature up to 250 ° C.

Glue ScanMix Firescanmix Fir (Finland, 600 rubles / pack.) It has a high softening temperature - 1,200 ° C. Scanmix is indispensable for lining

Outputs and solid fuel furnaces. Designed solution for masonry and repair

furnaces, as well as for laying tiles on simple surfaces.

Plovetonite SuperCompute Supercohol (Russia, 455 rubles / pack.) It allows the adhesion of a slim layer due to the presence of fine-grained fillers. Permissible use temperature up to 1,200 ° C.

Glue for the IVSIL TERMIXIVSIL TERMIX (Russia, 460 rubles / pack.). Adhesive high elasticity. The operating temperature is up to 250 ° C, which allows it to be used on the surfaces of the furnace away from the furnace and on fireplaces with a closed firebox. Glue

IVSIL Thermix is redard for solid bases.

Glue for the Lacker Tile Glue "Lacker" (Belarus, 260 rubles / 20 kg). Limit operating temperature up to 250 degrees Celsius.

Glue for furnace tile Bergauf Keramik Termobergauf Keramik Termo (Yunis, Russia, 450 rubles / pack). Glue Bergauf Ceramic Thermo is used for simple surfaces with heating temperature to + 180 ° C.

Glue SILTEK T-84SILTEK T-84 (Ukraine, 360 rubles / pack.). Glue Siltek is used for facing surfaces undergoing temperature differences within -

30 ° C - +150 ° C.

3. Special Ready Glue Solutions or Mastics

The line of these mixtures is represented by fewer grades.

This is due to the fact that the adhesive ability of the finished solution is lower than

obtained from a dry mixture. Nevertheless, the favor of the masters dropped:

The glue mixture "Parade K-77" Parade K-77 (Belarus, 300 rubles / 15 kg.). It is used on surfaces with heating temperature not higher than 800 ° C, it is distinguished by increased fixing properties. Not intended for use on plastered

surfaces.

Mixonit TERMO T24MIXONIT TERMO T24 glue mixture (Germany, 1130 rubles / 14 kg.). Glue Micxonite Thermo is used in the temperature mode (furnace surface) - 30 ° C - + 270 ° C.

Adracotterrical adhesive mastic (Russia, 220 rubles / 5 kg.). Mastic is suitable for facing surfaces reaching 1100 ° C.

A brief analysis of adhesive mixtures and solutions for laying tiles

on the furnaces and fireplaces makes it possible to conclude that there are significant them

variety, and the choice depends on many factors, which will allow

Perform a facing qualitatively and for a long time.

Article on the topic: How is your own okta sofa done?