For a long time, a familiar finish of the facade of the building with the help of plaster can not be called perfect. Even if the work is performed by an experienced master, such a finish has certain disadvantages:

- The surface requires careful preliminary preparation;

- Finishing work during the cold season is impossible;

- Even the reinforced sheath of plaster with the help of a reinforcing grid will not allow the surface of the original appearance, because under the influence of low temperatures and moisture, the finishing material will quickly crack and occasion.

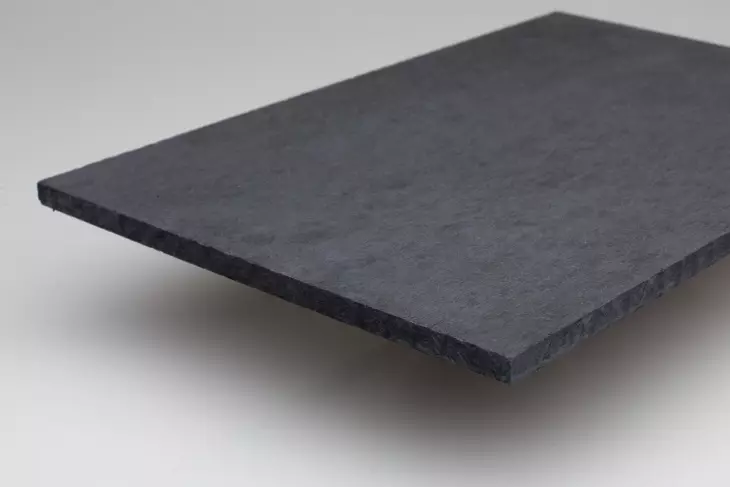

Fibro cement panels

Of course, I had previously had to put up and take shortcomings, but today, when a fibro-cement plate was created, it's time to forget about such problems.

A country that has developed such a miracle material is considered to be Japan, its goods are represented by the Kmew and Nichiha brands. But, and the Russian market did not lag behind, and goods such as Latonit and Rospan appeared. Workers who worked on the development of such plates were guided by the material:

- created a surface that will not crumble and crumble;

- was dense and flexible enough, but did not succumb to cracking;

- allowed to create a surface with a maximum service life and resistance to external stimuli;

- was not toxic and did not give in to the burning;

- It was easy to install.

The initial component for such a building material was found without problems, it became cement. Then, to protect the solution from cracking, the cellulose fibers were added to it, which served as a microarmatura and protected the mass of the deformation and increased its plasticity.

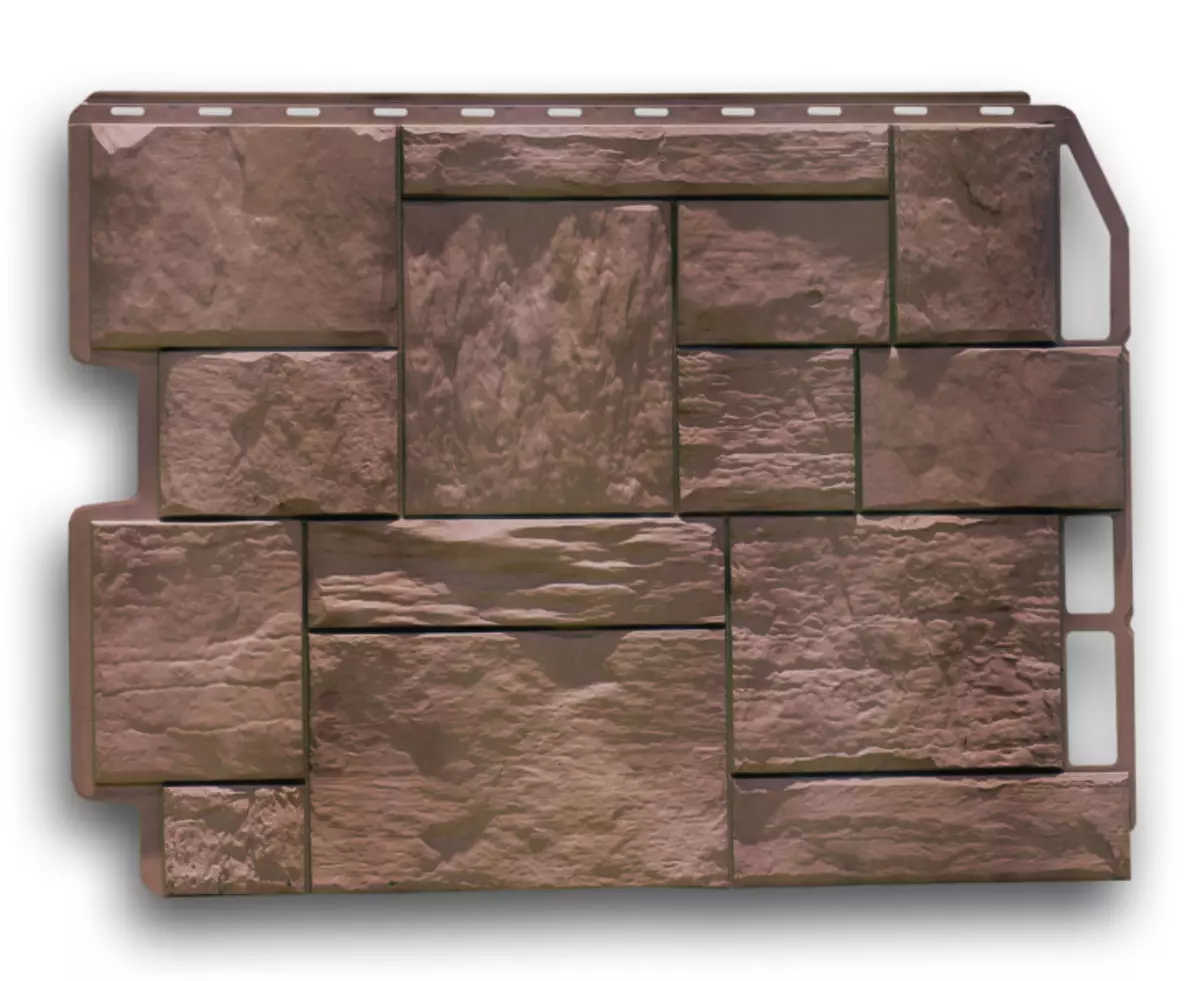

Fiber cement panels for finishing facades

At the next stage of development, additional ingredients were introduced into the material, which diversified the composition of their texture. Thanks to such components, the solution, up to its absolute frost, can be given absolutely any appearance, imitating wood, brick or natural stone.

Article on the topic: For which the guide headlock guide profile is used

By adding in a mixture of painting pigments, the color gamma material has conquered users with their diversity.

Unfortunately, the surface that was treated with cement solutions, very quickly absorbs moisture, so fiber cement plates need to be protected using varnish or silicone.

Characteristics and sizes

Fibro-cement panels for home

All technical features of this material are clearly spelled out in Guest, and should not deviate from the accepted rules that the Russian brand Latonitis is not always adhered to:

- The density of the material should not be less than 1.5 kg / cm3 (the company Latonite has observed this norm);

- Frost resistance must be withstanding no meter 100 cycles of temperature change and ensure coating 45-50 years of "life";

- The percentage of moisture absorption should not exceed 20% of the total weight of the slab;

- Bending strength should be about 24MP (before this indicator, the Russian canvas latonite does not reach a little);

- The shock viscosity of the material - should not be less than 2kj / m2, like the Russian manufacturer latonite;

- The average value of the material is 15-25kg.

Due to its high resistance to bending, the material can withstand the essential loads of the wind and the point blows of medium severity.

In the market of building materials, fiber cement plates are presented in a diverse dimensional range - from 182 to 303 cm, while their thickness is 45cm, and the width is from 1.2 to 1,8 cm.

Fibro-cement panels of Russian production have certain differences, and their thickness varies in the range of 0.6-1.6 cm. In addition to sizes there are certain differences in the shape of the edge for a joint, which provides high-quality fixation on the frame facing.

Montaja rules

Finishing with fibrotent panels

The most common and simple method of mounting plates is the fastening of the material to the carrier frame with the help of a dowel.

You can also perform work using stainless steel screws, which set, so that the caps can be hidden under a solution of hermetic paste.

Article on the topic: Make a lamp of the threads do it yourself

Since fiber cement plates are characterized by a special hardness, they are cut with a bladler with a disc from carbide materials. When work is suitable for an end, the joints of the material are covered with a hermetic mass, so that the moisture penetrates the gaps between the facing and the base of the wall.

Installation of decorative panels

If professionals work, in their work they use metal frames that are fixed with steel brackets. Then the dowel mounted a dense insulation and pressed the carrier profile.

After the fixation is done, proceed to the direct installation of the plate, after which all joints, seams and gaps are carefully treated with hermetic solutions.

The most common manufacturers and price category on fiber cement plates

Installation of fibro-cement panels

As we said, the birthplace of fibro-cement plates - Japan. Therefore, no one will be discovered that it is the Japanese companies that occupy leading positions. It is the materials from Japan in the construction market presented the highest quality, but also the cost of them is also high.

Today, the most popular is the Nichiha fibro-cement panels are considered the cost of which varies around 1600 rubles / m2.

Panels from Fibrcement

Among Russian manufacturers, such manufacturers are worthy of attention as: Latonit, Rospan. Of course, the level of such materials does not reach such Japanese competitors as Kmew. But, the company ROSPAN and Latonit is unworthy - the language will not turn. They represent their products in the budget price category, the average cost of 1M2 material is about 750-800 rubles.

The comparative characteristics of Russian companies Rospane and Latonit, as well as the Japanese company KMEW, are shown in the table below.

| Manufacturers | Material indicator | |||||||||

| Width (mm) | Length (mm) | Thickness (mm) | Bending strength tensile (MPa) | Shock viscosity (KJ / M2) | Density (g / cm3) | A combustion group | Water absorption (%) | Frost resistance (cycles) | Cost 1m2 ($) | |

| Latonit. | 200. | 1800. 3000. 3600. | eight | 21.5 | 2. | 1.5 | Mr. | ≤18 | 100-120 | twenty |

| ROSPAN | 306. 455. | 1590. 1593. | fourteen | 45-65 | 2. | 1,2 | Mr. | ≤16 | 100 | 29. |

| Kmew. | 450. 910. | 1820. 3030. | 12-30 | 50-57 | 2.6 | 2-2.5 | Mr. | ≤10 | 150. | 45-60 |

Article on the topic: What are the coverage for interroom doors

Decorative panels for the facade

As you can see, the Japanese production material of KMEW is much more expensive than the Russian Latonit and Rospan, but also characteristics differ markedly for the better.

We tried to tell you about the most common brands, such as Rospan, Latonit, Kmew and Nichiha, described their characteristic features, and what to choose - to solve you.