In boilers, like other heating installations, not all heat, which is allocated during the combustion of fuel is used. Pretty most of the heat leaves with the products of burning into the atmosphere, the part is lost through the boiler housing and the small part is lost due to a chemical or mechanical lack of delivery. Under the mechanical negligence is understood as the loss of heat due to failure or depreciation of the ash elements with unburned particles.

The heat balance of the boiler is the distribution of heat that is released when burning fuel, for useful heat used for its intended purpose, and on heat loss, which occur during the operation of thermal equipment.

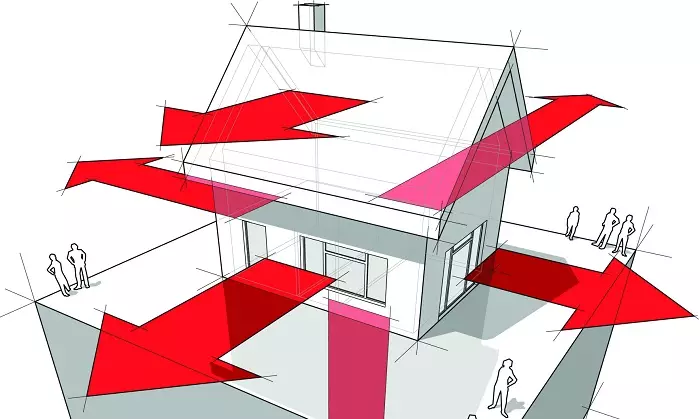

Scheme of the main sources of heat loss.

The value of the magnitude that could stand out with the lower heat of the combustion of all fuel is taken as the reference value of the arrival of heat.

If a solid or liquid fuel is used in the boiler, the heat balance is in kilodzhoules relative to each kilogram of the consumed fuel, and when using gas, relative to each cubic meter. And in that, in another case, the thermal balance can be expressed as a percentage.

The thermal balance equation

The heat balance equation of the boiler when burning gas can be expressed by the following formula:

The optimal load parameters provide high productivity of the heating system.

- Qt = Q1 + Q2 + Q3 + Q4 + Q5 + Q6;

- where Qt is the total amount of thermal heat that was enrolled in the boiler furnace;

- Q1 - useful heat that is used to heat the coolant or obtain steam;

- Q2 - heat loss, which goes along with combustion products into the atmosphere;

- Q3 - heat loss associated with incomplete chemical combustion;

- Q4 - the loss of heat due to the mechanical unimportant;

- Q5 - heat loss through the walls of the boiler and pipes;

- Q6 - heat loss due to the removal of ash and slag from the furnace.

As can be seen from the thermal balance equation, when burning gaseous or liquid fuels, there are no Q4 and Q6 values that are characteristic only for solid fuels.

If the heat balance is expressed as a percentage of total heat (Qt = 100%), this equation takes the form:

- 100 = Q1 + Q2 + Q3 + Q4 + Q5 + Q6.

If each member of the heat balance equation from the left and right side is divided into qt and multiply it by 100, then the heat balance will be a thermal balance as a percentage of the total amount of heat.

- Q1 = Q1 * 100 / Qt;

- Q2 = Q2 * 100 / Qt and so on.

If liquid or gaseous fuel is used in the boiler, then the losses Q4 and Q6 are missing, the heat balance equation of the boiler in percentage takes the form:

- 100 = Q1 + Q2 + Q3 + Q5.

Each type of heat and equation should be considered.

The heat that was used for the purpose (Q1)

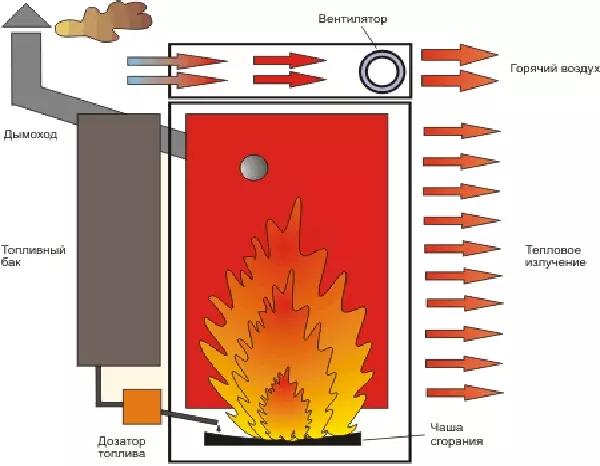

The scheme of the principle of operation of a stationary heat generator.

The heat that is used for direct purpose is that the heat carrier is spent on the heating of the coolant, or the preparation of the pair with a given pressure and the temperature, which is considered from the temperature of the water boiler econaider. The presence of an economizer significantly increases the amount of useful heat, as it makes it possible to mostly use heat, which is contained in combustion products.

Article on the topic: Planning 1-storey house with three bedrooms - choose a project to taste

When the boiler runs, the elasticity and pressure of steam inside it increases. The boiling point of water depends on this process. If, under normal conditions, the boiling point of water is 100 ° C, then when the pair pressure increases, this indicator increases. At the same time, the pairs, which is in one boiler along with boiling water, is called saturated, and the boiling point of water at a given pressure of the saturated pair is called the saturation temperature.

If there are no water droplets in the pair, then it is called dry saturated ferry. The mass proportion of dry saturated steam in a wet pair is a degree of dryness of steam, expressed as a percentage. In steam boilers, the humidity of the steam ranges from 0 to 0.1%. If the humidity exceeds these indicators, the boiler does not work in optimal mode.

Useful heat, which is spent on the heating of 1 l of water from zero temperature to boiling point at a constant pressure, is called the enthalpy of the liquid. The heat consumed for the translation of 1 l of boiling fluid into the vapor state is called the hidden heat of the vaporization. The sum of these two indicators is the general heat content of a saturated steam.

Heat losses with combustion products, leaving the atmosphere (Q2)

This type of percentage losses shows the difference in the enthalpy of outgoing gases and cold air entering the boiler. Formulas for determining these losses differ when using different types of fuel substances.

The burning of fuel oil leads to the loss of heat due to a chemical non-delivery.

When using solid fuel, Q2 loss is:

- Q2 = (Ig-αg * i) (100-Q4) / Qt;

- where Ig is the enthalpy of gases flowing into the atmosphere (KJ / kg), αg is an excess air coefficient, IV is an enthalpy of air required for combustion, at a temperature of its receipt to the boiler (KJ / kg).

The Q4 indicator is introduced into the formula because it should take into account the heat released during physical burning of 1 kg of fuel, and not for 1 kg of fuel entered into the furnace.

When using gaseous or liquid fuels, the same formula has the form:

- Q2 = ((Ig-αg * iv) / Qt) * 100%.

Heat losses with outgoing gases depend on the state of the heating boiler and the operating mode. For example, when manual loading of fuel in the heat loss of this type is significantly incremented due to the periodic fifth of fresh air.

The loss of thermal energy with flowing in the atmosphere with smoke gases increases with increasing temperature and the amount of consumable air. For example, the temperature of the gases flowing into the atmosphere in the absence of an economizer and the air heater is 250-350 ° C, and when they are presence, only 120-160 ° C, which increases several times the value of the useful heat used.

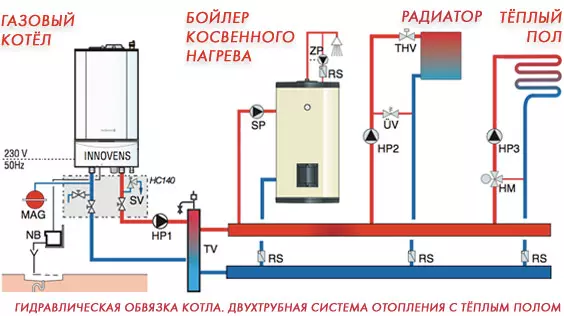

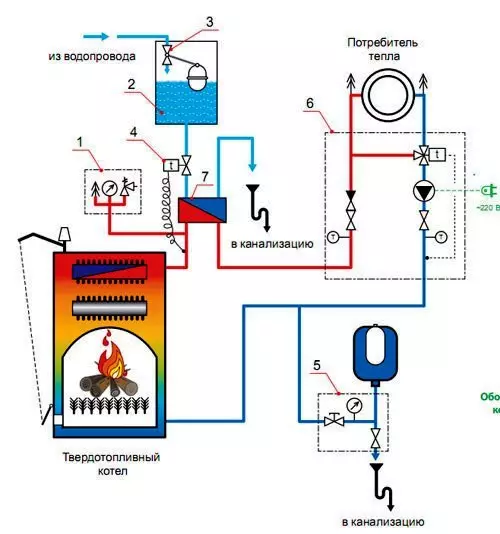

Boiler strapping scheme.

On the other hand, the insufficient temperature of the outgoing combustion products can lead to the formation of water vapor condensate on heating surfaces, which also affects the formation of ice growths on flue pipes in winter.

Article on the topic: Is it possible to make a balcony if it is not: all "for" and "against"

The amount of consumable air depends on the type of burner and the operation mode. If it is increased compared with the optimal value, this leads to a high air content in the outgoing gases, which further carries part of the heat. This is an inevitable process that cannot be stopped, but can be brought to minimum values. In modern realities, the air flow coefficient should not exceed 1.08 for the burners with complete injection, 0.6 - for burners with incomplete air injection, 1.1 - for burners with forced feed and mixing air and 1.15 - for diffusion burners with external mixing. To increase the heat loss with the outgoing air, the presence of additional air supersers in the furnace and the boiler pipes. Maintaining air flow at the optimal level reduces Q2 to a minimum.

To minimize the value of Q2, it is necessary to brush the external and inner surface of the boiler in a timely manner, follow the lack of scale, which reduces heat transfer from the combed fuel to the coolant, comply with the requirements for water used in the boiler, monitor the lack of damage in the boiler and pipe connections so as not to Admit air inflows. The use of additional electrical heating surfaces in the gas tract spending electricity. However, savings from the optimal fuel consumption will be much higher than the cost of electricity consumed.

Heat losses from chemical fuel chemical (Q3)

This type of scheme ensures the protection of the heating system from overheating.

The main indicator of incomplete chemical combustion of fuel is the presence of carbon monoxide gases (when using solid fuels) or carbon monoxide and methane (when burning fuel gaseous). Warm losses from chemical nosta are equal to the heat that could stand out when burning these residues.

The incomplete combustion of fuel depends on the lack of air, poor fuel mixing with air, reducing the temperature inside the boiler or when contacting the flame of burning fuel with the walls of the boiler. However, an excessive increase in the number of incoming oxygen not only does not guarantee full combustion of fuel, but can disrupt the operation of the boiler.

The optimal content of carbon monoxide at the outlet of the furnace at a temperature of 1400 ° C should be not more than 0.05% (in terms of dry gases). With such values of heat loss from the unjit, they will be 3 to 7% depending on the fuel. The lack of oxygen can bring this value up to 25%.

But it is necessary to achieve such conditions so that the chemical nonsense of fuel is absent. It is necessary to ensure the optimal air intake in the furnace, maintain a constant temperature inside the boiler, achieve a thorough mixing of the fuel mixture with air. The most economical work of the boiler is achieved when the content of carbon dioxide in the combustion products, reaching the atmosphere, at a level of 13-15% depending on the type of fuel. With an excess of air intake, the content of carbon dioxide in the outgoing smoke may decrease by 3-5%, but the heat loss will increase. With the normal operation of the heating equipment, the loss Q3 is 0-0.5% for dust carbon and 1% for layer furnaces.

Article on the topic: Quad bike do it yourself

Warm losses from physical lack of delivery (Q4)

This type of losses occurs due to the fact that the unburned fuel particles fall through grate in the ash bar or are carried away with the products of burning through the pipe into the atmosphere. The loss of heat from physical unjiting directly depends on the design of the boiler, the location and shape of the grave, the forces of the thrust, the state of fuel and its stem.

The most significant losses from the mechanical nearesta with a layer burning of solid fuel and is overlooked. In this case, a large number of small unburned particles are carried away along with the smoke. This is especially well manifested when using inhomogeneous fuel, when it alternate small and large pieces of fuel. The burning of each layer is obtained inhomogeneous, as small pieces are burning faster and worn with smoke. In the resulting intervals, air flows, which cools large pieces of fuel. At the same time, they are covered with slag crust and do not fade completely.

Heat loss in mechanical incommory is usually about 1% for dust shafts and up to 7.5% for layer furnaces.

Heat loss directly through the walls of the boiler (Q5)

This type of loss depends on the shape and design of the boiler, the thickness and quality of the ceiling of both the boiler and the chimney pipes, the presence of the heat insulating screen. In addition, the construction of the firing itself has a large influence on the loss, as well as the presence of additional surfaces of heating and electrical heaters in the smoke path. These heat losses increase in the presence of drafts in the room where heating equipment is standing, as well as on the number and duration of the opening of the furnace and the line of system. Reducing the number of losses depends on the correct winding of the boiler and the availability of the economizer. It is favorable at a decrease in heat losses affects the thermal insulation of pipes, through which the exhaust gases are removed into the atmosphere.

Heat loss due to the removal of ash and slag (Q6)

This type of loss is characterized only for solid fuel in a slicing and dust-shaped state. With his incomplete, the incomplete fuel particles fall into the ash bar, from where they are removed by carrying out a part of the heat. These losses depend on the ashiness of fuel and slag adoration.

The heat balance of the boiler is a magnitude that shows the optimality and efficiency of your boiler. The magnitude of the thermal balance can be deciding with measures that will help save the fuel combined and increase the efficiency of heating equipment.