The polystyrene foam is today one of the most popular insulation due to the low price and ease of use. The most effective foam in the exterior insulation of walls and foundations of buildings. In this regard, there is a need to use adhesive compositions to strengthen foam plates on concrete, brick and other surfaces. Selecting the adhesive agent, it is necessary to take into account that it should not contain organic solvents, such as acetone or gasoline, which negatively affect the polystyrene. Today there are many options for what to glue expanding polystyrene foam. Consider the most common of them.

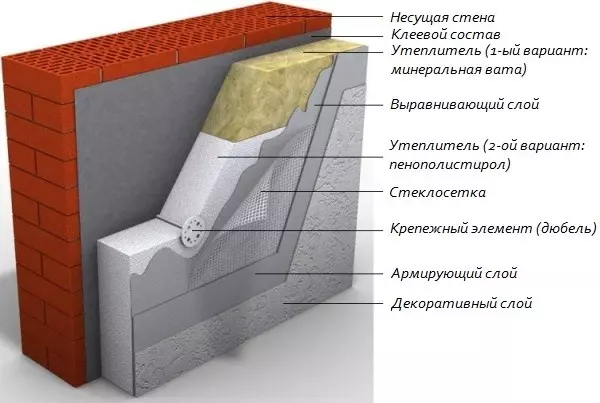

Wall insulation diagram polystyrene foam.

Polyurethane foam glue

The use of special polyurethane glue implemented in cylinders contributes to an increase in the speed and improvement of the quality of the insulation of concrete surfaces.

It is this fact that is the main advantage of this type of adhesive means. The technology of work on the installation of foam on concrete requires compliance with a 3-day technological break after gluing polystyrene foam plates and until the attachment of their dowels. This, accordingly, increases the total duration of all works. Using polyurethane foam glue, it is possible to reduce the technological break to 1 day.

Benefits of polyurethane foam:

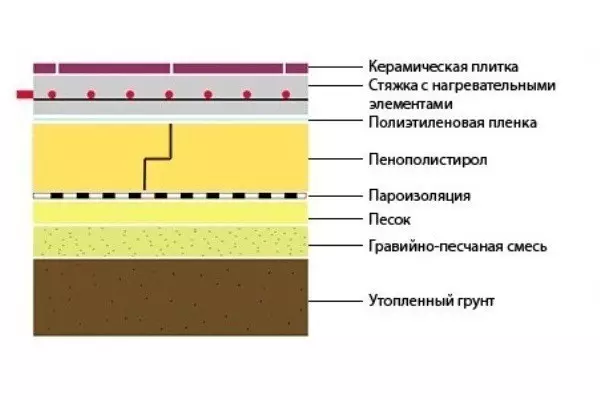

Floor insulation scheme polystyrene foam.

- Ideal for gluing foam plastic to concrete;

- Reducing the timing of the insulation up to 3 times;

- The technological characteristics of adhesion of glue-foam with a concrete surface is much higher than a simple dry adhesive mixture;

- moisture resistance indicators are higher than dry mixtures;

- Small consumption: 10 square meters requires only 1 cylinder;

- The cost of such adhesive is similar or a bit more expensive than dry adhesive compositions (depending on the manufacturer);

- Simultaneously with the sticking plates, filling the foam of the joints, which effectively prevents the formation of cold bridges;

- Polyurethane foam is sold already ready for use, so the quality of gluing will not depend on the human factor (errors in the preparation of glue) and throughout the entire volume of work will be stable.

Article on the topic: Welding inverters of Resanta: Sai, Sai Mon, Sai K, Reviews, Prices, Operation

Use dry adhesive mixes

For fastening polystyrene foaming to concrete, specialized dry adhesive mixtures of several species can be used. The composition of dry glue, except for cement, includes fillers and mineral supplements. Some of the dry adhesive mixtures can only be intended for fastening foam, while others - for fastening and subsequent reinforcement of the surface of the insulation. The difference lies in the amount of polymers included in their composition. For example, dry CRP Glue, the Ceresit produced, has a universal purpose, and the ST-83 is used only for the installation of foam. ST-85 contains more polymers, therefore it is more plastic and durable, but it is one and a half times more expensive than ST-83.

Today in the construction products market are presented dry adhesive mixtures for polystyrene foam from various manufacturers. Choosing the necessary material, you should not give preference to too cheap it from an unknown company. As a rule, such adhesive may have poor plasticity, insufficient strength and resistance to environmental impact. This may further significantly reduce the service life of the insulation system.

The main advantages of dry adhesive for foam:

- has a high degree of adhesion with concrete and other surfaces;

- Quickly hardens - the prepared glue must be used within 2 hours after cooking;

- possesses vapor permeability;

- has good plasticity;

- easy to use;

- 1 glue bag is enough for 5-6 square meters;

- Comparatively low cost.

A dry mixture before use must be prepared correctly, observing the necessary proportions of the dry component and water. In a container with a measured amount of water, dry glue is covered and gearly mixed with a construction mixer. This operation must be performed, fully immersed the blade into the solution in order to prevent air bubbles from entering, which greatly reduces the quality of the adhesive. When you put a solution for about 15 minutes, it is mixed again until the lumps of lumps.

Article on the topic: Decorative flowerbeds: The ideas of planting greenery in the garden (44 photos)

In order to glue polystyrene foam to concrete, you can use frost-resistant facade glue, liquid nails or tile glue. However, guaranteed qualitative performance of work can only be using specially intended for foam of funds: dry glue or polyurethane foam.