The ability to maintain heat and create comfort in the wood house retains both small fragments compress in the stove. Different types of chipboard and fiberboard have found an application in alignment of walls using dry plaster technology, creating partitions. Outside, they are used for insulation, cladding and decoration of the facade, we create platbands for windows and doors. In the furniture industry from laminated sheets make the front of the furniture and the rear walls of their pressed sawdust. The material is easy to work with your own hands.

Stove

Building materials from production waste significantly cheaper

Wood-chip

In the woodworking industry, including all its species, less than half of the volume of wood are used. Even after removing branches and removal of the cortex, a uniform drawing of the boards spoil the bitch and the swamp. Now they make panels and plates from:

- chips;

- sawdust;

- shavings;

- Crimping, loose on the fibers.

The material has features close to natural wood. Strength and ability to resist water without warping above. The cost of such a finish is significantly lower. You can make insulation and budget repair with your own hands.

Wood-chipped stove for walls

To give a decorative species, the surface of the plate is treated in various ways. Apply:

- grinding;

- lamination;

- cladding;

- Staining.

Inside buildings from chip and fiber plates make partitions and doors with good thermal insulation and quenching noise. Thin sheets are used to finish the walls, creating niches, shelves and other elements of the interior. Tubes made of pressed wood sawdust decorate windows and doors inside and outside of houses. Knowing simple material processing rules, you can make repair with your own hands.

Article on the topic: How to assemble a coffee table with your own hands

Characteristics of wood fiber materials

Wall decoration chipboard

Wood fiber is located in the plates longitudinally or perpendicularly. The outer layers are dense and between them a more loose layer. This division can be seen from the end of the plate. The main types of fiberboard:

- organitis - lined fibreboard;

- biopustic;

- with the addition of bitumen;

- challenged.

Wood-fiber plates have different hardness and sizes. They are used for finishing and insulation of facades, creating sound-absorbing partitions. The fiber canvas serves as an excellent material from which you can make noise insulating doors and platbands for interior facilities with your own hands and buy ready-made. For the interior it is better to use biostroof plates with minimal excretion of harmful substances.

Wood-fiber materials are better glued to the wall than to fix with self-tapping screws to the frame. The screws should be kept in loose material and fall out over time. To finish, hanging the shelves and decor you can use a dowel, scoring them into solid wall laying material.

Pressed chip stoves in the creation of the interior

Wall sheat wood chipstones

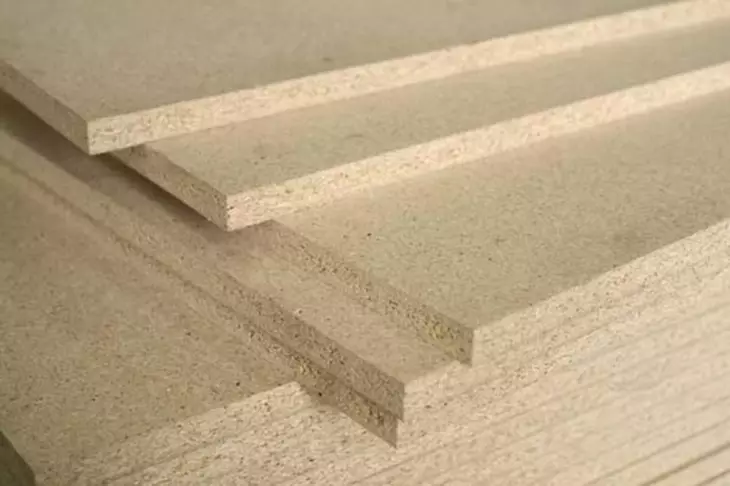

Wood-chip plates are made of chips with pressing with a binder composition of synthetic resins. The loose medium layer is obtained from larger fragments. External dense and grinding treated. Through density and hardness distinguish three main types. They are presented in the table.

| Group | Stove | Specific weight, kg / m3 | Application area |

| one | Insulating | 250-400. | For wall decoration, heat and noise insulation |

| 2. | Middle density | 400-800 | wall covering, insulation insult and facade |

| 3. | High hardness | 300-1200. | Creating internal partitions, stairs, shelves, niches, platbands |

After grinding on the part of the product, a decorative finish of the surface of the chipboard is made. Used:

- lamination;

- Cashing.

The first method is covered with paper with wax and resins, high pressure. The decorative surface becomes part of the plate.

Cashing does not require special equipment. You can glue the film to the surface with your own hands. The disadvantage in a weak clutch in the corners and edges.

Article on the topic: Alerts Embroidery Cross Schemes: for home Prayer, seven for the whole family, name for free, download for men

For interior decoration, a wood-stove with marking E-1 containing the smallest amount of formaldehyde is suitable. This type of chipboard is allowed to create children's furniture. The craftsmen can make it with their own hands and use sheets for residential premises, make and install platbands for interior doors.

A large selection of chipboard finishes imitates veneer of various tree breeds. This allows you to give panels and walls of the inside of the house the type of sheathing with natural boards or clapboard. Make a combination - glue the film, you can finish installing wood-chipboard or after cutting to finishing with your own hands. The platbands are constantly being friction and shocks, so they are better to buy laminated ready.

Internal architectural elements from chipboard

Chipboard for walls

During the construction of the house with their own hands, solid chipboard can replace natural wood when creating many elements of interior architecture:

- steps of stairs;

- partitions,

- base under floor covering;

- ceiling liner;

- Alignment of walls;

- platbands;

- Arch design;

- Niche and built-in wardrobes, hiding pipes and counters.

For wall decoration, especially at dachas and in wooden houses, chipboard one of their best budget options. The multidirectional arrangement of the chips eliminates the warming when the water and temperature drops are injected. In buildings with seasonal accommodation, you can use moisture-resistant options for interior decoration. They have a greenish shade from impregnating antipyrin.

Manufacturers began to produce tipped chipboard, including moisture resistant. The decorative film on them can be easily glued with your own hands after finishing completion. When building a house, they are used as a formwork, walls of walls and floors.

Facade decor from Fiberboard and chipboard

Wall decoration chipboard

Lamination makes the surface of the chipboard stable to enter the surface of moisture walls. When working with such panels, it is important not to forget carefully, isolate ends and places of saws by self-adhesive film or primer. When finishing the facade, moisture-resistant sheets with subsequent putty and painting are used.

Article on the topic: How to paint the window with a wooden frame?

The solid material is poorly fine processing. Creating carved platbands on the windows, you have to use special cutters. Then the surface is grinning and after deep impregnation, the primer is painted.

Ready-made platforms of simple configuration are sold in stores with laminated moisture-resistant coating under various wood species.

High hardness chipboard is used to create cottages with lacquer. Materials from sawdust are perfectly suitable for the insulation of wooden houses. At the same time, decorative elements of the facades are created and mounted on the walls with glue and self-tapping screws. Be sure to be a facing that protects against direct water ingress, UV rays. You can make a wet facade and ventilated.

Fiber and chip stoves are widely used in the furniture industry.

Installation of wood chipboard with your own hands

In the furniture industry is widely used by chipboard. Laminated sheets go to the front and sides. The manufacture of the rear wall is used non-lined materials from fine chips or sawdust. It is much cheaper than products from natural solid wood.

Making cabinet furniture with their own hands, it must be remembered that the base should be from wooden bars or metal profile. Under the screws holes are drilled. Elements additionally plant for special glue. To attach accessories under the self-tapping screw, it is desirable to use adhesive putty. It will keep the material from destruction and the screw will stay for a long time.