Computer tables made of wood are durable furniture that is easily manufactured at home. It will take advantage of the drawing of a table from a natural tree.

A computer table made of wood is characterized by high strength and high service life.

The scheme indicates the parameters of each element. Natural tree of the desired size can be ordered on the sawmill.

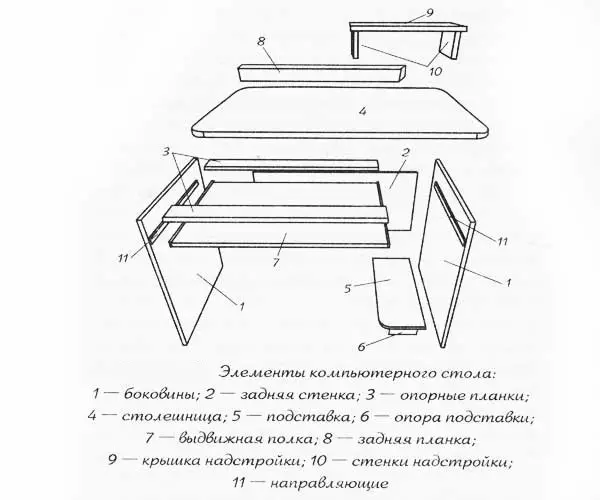

Components

Design and size scheme and size of a computer table.

A similar table made of wood is compact and multifunctional furniture, which is designed to accommodate a computer and its components. From a constructive point of view, such furniture from the wood array should have a table top, 2 shelves and a cabinet with drawers. In the manufactured model under the tabletop, a shelf is provided for installing a system unit, an open niche for storing various trifles and a retractable stand for the keyboard.

A computer table made of natural wood can be made from a mobile, appropriate or built-in table. It can be performed in several versions. It can be done with an open or closed niche, with drawers and suspended. The size of the couch and its species depend on the user's personal preferences. The length of the product fluctuates in the range of 350-430 mm, and the depth depends on the same parameter of the table itself. For the lower base of the couch, the height is 50-60 mm. The optimal option is considered to manufacture a handful of a tree with a 400 mm long and a height of the length of the drawers of 160 mm.

A computer table from an array can be made with an appropriate bed, which is an autonomous design. Such a model is attached to the framework of the main product. The height of the internal stand must be coincided with the same table indicator - 750 mm. The standard length of the couch with a compartment for the system unit is 700 mm.

Article on the topic: Electric flow water heater per shower: how to choose correctly

Computer desk can be equipped with a mobile table. This autonomous part is equipped with wheel supports, which allows it to freely move relative to the main structure. The product under consideration is equipped with drawers, shelves and other cells that are intended for storing stationery and other accessories. The length of the standard mobile cabinet reaches 400 mm, the depth is 500 mm, and the height is 575 mm. This product can be installed under the table or next to it.

Preparatory work

To make a computer table with your own hands, the following materials will be needed:

For assembly of a computer table, pine furniture shields will be needed.

- pine furniture shields;

- 6.2 m long board;

- plywood leaf (6x1525x1525 mm);

- sandpaper;

- varnish.

For the manufacture of a computer table, special accessories and fasteners will be required. Experts recommend buying 3 sets of balls or roller guides with a length of 500 mm. The last species is different from the ball analogue of a low price. From a technical point of view, roller guides are not extended. They are fragile and quickly fail. For the retractable stand you will need to buy 1 set of 400 mm long. Of the accessories and fasteners will be needed:

- Sucks;

- 50 self-tapping screws (5x60 mm);

- 3 handles for drawers.

The production process is carried out with the help of hacksaw, drill, drills, screwdriver, square, chisels, roulettes, grinding machine. Pre-mark markings and cut the main parts of the table: a worktop, 3 walls, bottom and lid of the couch. The walls need to cut into 2x2 cm fragments of the upper front corners in 2x2 cm. Each speaker is spilled using the sandpaper.

On the rear edge of the central wall make a sample with a 200 mm width and a depth of 18 mm, while the height of the floor level of 265 mm is observed. In this place the transverse panel made from the shield is installed. Its parameters are 18x200 mm. It is designed to connect 3 vertical sides. To the 2nd sides, the board is screwed in bulk with self-tapping screws.

Article on the topic: Niche in the bathroom: photo assembly Shelves from drywall

A computer table that is equipped with a transverse bar has significant rigidity. The next step involves driving the corresponding holes in the right places. The lower frame is collected using self-tapping screws.

Table manufacturing process

Assembling circuit of computer table elements.

To make a stationary shelf to install the system unit, you will need to cut the horizontal niche and the side small wall. To do this, it will take to cut the front upper corner of the sidewall, rounded with its sandpaper. Similarly, come with an rear bottom angle (for plinth). A small sidewall is screwed to the shelf and to the rear panel. Then the 1st part is fixed to the big sideway. The lower openings provided under the shelf and a bed are covered by panels. To fix them, uses without glue.

The next stage provides for the manufacture of superstructure. Pre-prepared pattern. Holes drill in its ends and applied to the computer table lid. To properly make a computer table, apply a square. It is designed to check the design geometry. Self-tapping screws are screwed into the lid. Previously holes in the table top are combined with sockets in the sides.

Then make markup, cut the shield in size in 400x2000 mm. The following details are obtained:

- upper shelf with a width of 315 mm;

- Cross-plank-boat.

The vertical average wall is cut from a shield of 200x2000 mm. It is screwed to the tabletop with screws. Pre-prepared the template and make holes.

The linearity of each compound is controlled by the coated.

The next stage is to install the rear layer-sided. The upper shelf is stacked on the end of the central wall, aligned and is screwed to the sidelines to the sidewols, and then to the line of the average plank. The left shelf is pumped out of a shield with a width of 200 mm.

The walls of the drawers are made from a 12x120 mm board. The bottom of the niches cut out of plywood. The obtained billets are twisted with self-drawers, the bottom is sewn. The guides are fixed from below, while the indent is 18 mm from the front edge of the sideways.

Article on the topic: how to glue the wallpaper on the wall and in the corners

Then manufactured from the array stand for the keyboard. The computer table disassembles, each part it is grouped and covered with varnish. Details are dried. Furniture is going. If necessary, the compound is enhanced with joinery glue. Then saw 3 facial planks. Make markup and drill holes in them (for handles). Accessories screws will simultaneously fasteners between the walls of the niche and the facing. To set the panels in the opening of the cabinet, the clins are used. Marking is carried out. Pens are tightened with long screws. Additionally, you can screw the screws. Computer table is ready to operate.