Content:

- The advantages of the material and the possibility of its painting

- Factory making painted galvanized sheet

- A small overview of the coloring substances

- Using galvanized subsystems

Galvanized steel is quite common for use with the material, but the coating zinc does not allow fully protecting the metal from corrosion manifestations. Of course, due to the thin layer of zinc, the material becomes durable and more protected from negative atmospheric influence, but zinc although at least, but also is also subject to the processes of the appearance of rust. I want to tell what caused the popularity of galvanized subsystems, as well as the colored galvanized sheet.

Galvanized leaf

The advantages of the material and the possibility of its painting

Galvanized painted sheet

In order not to move away from the topic, I immediately want to start with the advantages of using galvanized sheets, since only the facts are important for any master:

- The low cost of the galvanized metal makes it very popular for roofing works.

- Manufacturers assure that zinc coating allows you to extend the use of metal to 20-30 years

- Material is environmentally friendly

- Acceptable appearance of galvanized sheet

- Due to the properties of the reflection, the galvanized sheet is not so heated under the sunny rays

Despite such good advantages, the zinc coating is also subject to corrosion and, unlike all the usual rust, a white flare appears on such a material.

Important! Together with the above, it becomes clear that for the material it is necessary to apply additional protection and this exists. Galvanized sheet coloring is the most popular way that is used both at home and in production.

For painting sheet it is necessary to use only certain types of paints. For example, oil paint for such purposes is not suitable due to the lack of its elasticity and the necessary properties of adhesion. If you want to paint galvanized leaf at home, then choose from such materials as:

- Fire retardant composition

- Zinga zinc mixture

- Acrylic paint

Article on the topic: Tapestry Curtains: Luxury in the interior

Factory making painted galvanized sheet

Colored galvanized sheet

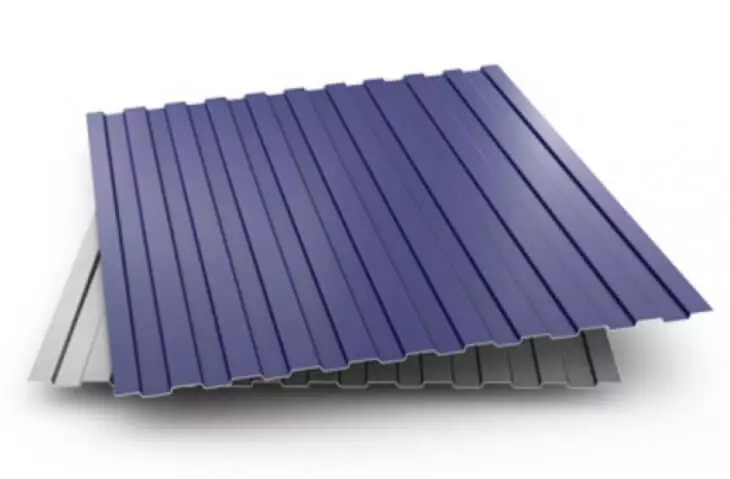

In some cases, painting work at home is not at all relevant. This is due to the possibility of acquiring inexpensively ready-made material. Sheet painted galvanized is beneficial from the side of financial resources, it is produced by manufacturers in rolls. Such enterprises also cut out sheets and some firms offer cuts by individual order. Standard sizes manufactured by manufacturers have parameters:

| Name | Value |

| Thickness | From 0.4 to 1.2 |

| Length | Up to 2.5 m (individual order allows manufacturing up to 12 m) |

| Width | 710-1800 mm |

Important! The material manufacturer packs its goods to polyethylene film. Before use, such a film is removed. Thus, when transporting painted sheets, their surface is not damaged.

Interestingly, these sheets can be stained on both sides, and for the process itself, mixtures with anti-corrosion additives are used. Thanks to this, we can note the following advantages:

- Moisture resistance

- Beautiful adhesion with staining surfaces

- Resistance to ultraviolet. Does not burn out

- Easy tolerance of sharp temperature drops

Painted materials are obtained by improved durability. Metal sheet is different:

- Much more durable than ordinary galvanized

- Attractive appearance, together with the possibility of choice

- Simple installation technology, while light weight allows you to perform work independently widespread by a friend

- Used not only for roofing works, but also to build partitions, as well as ventilation systems and facing facades

- Using this material, elements of eaves, drainage systems, exterior window sills are manufactured. Together with the ability to choose color, any buyer with ease will select the painted galvanized sheet into the tone of the roof

From the shortcomings, I allocated a couple of moments, which in many cases can be corrected:

- Lack of sound absorption - all blows of rain drops, as well as branches of trees will be heard residents of the house

- Low thermal insulation indicators - to use this material it is best to carry out overlabit insulation

Article on the topic: Interesting options how to decorate aquarium

A small overview of the coloring substances

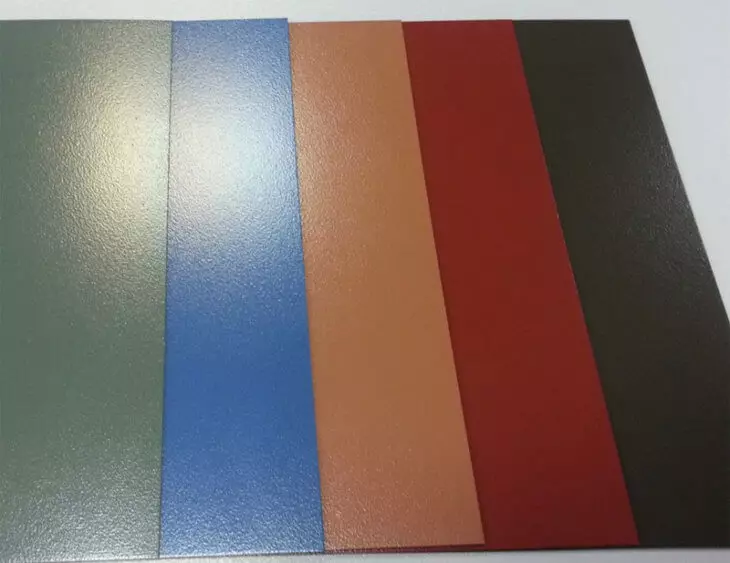

Galvanized sheets

Since we have already found out which paints are suitable for painting with their own hands, let's look at each of them:

- Acrylic compositions are well suited for galvanized surfaces. Thanks to good adhesion, they are firmly connected by the base of the decoration. Such paint can be painted as in one layer and two. At the same time, all technical standards will be fully respected. According to the method of application, everything is very simple: if you have the ability to use the collapse, it is wonderful, if not, then the use of a brush or roller will fit

- Zinga is a single-component composition on a zinc-based basis. In this case, the component of the zinc is large enough - approximately 96%. Such a mixture can be used to restore a galvanized sheet after damage to its coating. Before staining it is necessary to carry out mechanical stripping of the base, to create the necessary roughness

- Polystyl is a fire retardant paint that can be used indoors. The coating will have their own protective properties within an hour in the presence of open fire. Drying this composition occurs during the day, but not less

Using galvanized subsystems

Galvanized sheets and painted

Due to its availability, the galvanized subsystem is popular for use. In addition, it is quite durable and reliable, moreover, its properties make it possible to withstand significant cladding materials. As a material, you can use both artificial and natural stone or porcelain stoneware.

As already mentioned with all its reliability, the sheets are still subject to corrosion, so it will not be superfluous to carry out an additional coating of the material with polymers. Galvanized elements are designed to improve building processes, especially in the case of work with their own hands. One of them is a perforated galvanized corner, which is used under the plaster. It is used not only to protect corners from mechanical damage, but also for accurate elimination. With its help, many masters are separated by both internal and outer angles, while the surface of the surface becomes more attractive, and the process of removing 90 degrees is much simplified.

Article on the topic: Translucent designs

If you decide to use galvanized sheets as finishing at home, think in advance about the possibility of purchasing already ready-made painted materials. If this feature is not useful, and you want to protect the already existing root, then use special paint materials with the necessary requirements and properties.