Installing additional or basic heating through a warm floor becomes popular. This type of heating allows you to maintain comfortable temperatures and save on power saving. The warm floor is divided into electric and water type. The second has more flexible characteristics: a democratic price, absolute security and energy consumption saving during operation. It is this type of heating of the floors that prefer to install in homes and apartments.

Increasingly, the water type of heating becomes the main, since heat distribution is much more efficient than that of heating with radiators. This is due to laying coolants throughout the useful area of the room. The pipes warm the concrete tie, which perfectly holds heat and gives it into space.

Installation of water heating floor does not differ from the installation of a common classical heating system. It is preferable to connect a system to an autonomous source of hot heat carrier - boiler. Thus, it will be possible to adjust the temperature of the water and the efficiency of the system.

The warm floors imply, first of all, the installation of the boiler, the distribution manifold and the circulation pump. Without these elements, the floor will not work. So laying pipes under the screed is only the beginning of the main work on the installation of water floors. Of course, the boiler itself will become the main element of the heating system. But without a collector, the challenge of the boiler disappears. In this regard, it should be carefully taken to the installation and selection of the distribution unit.

Why do you need a distribution unit?

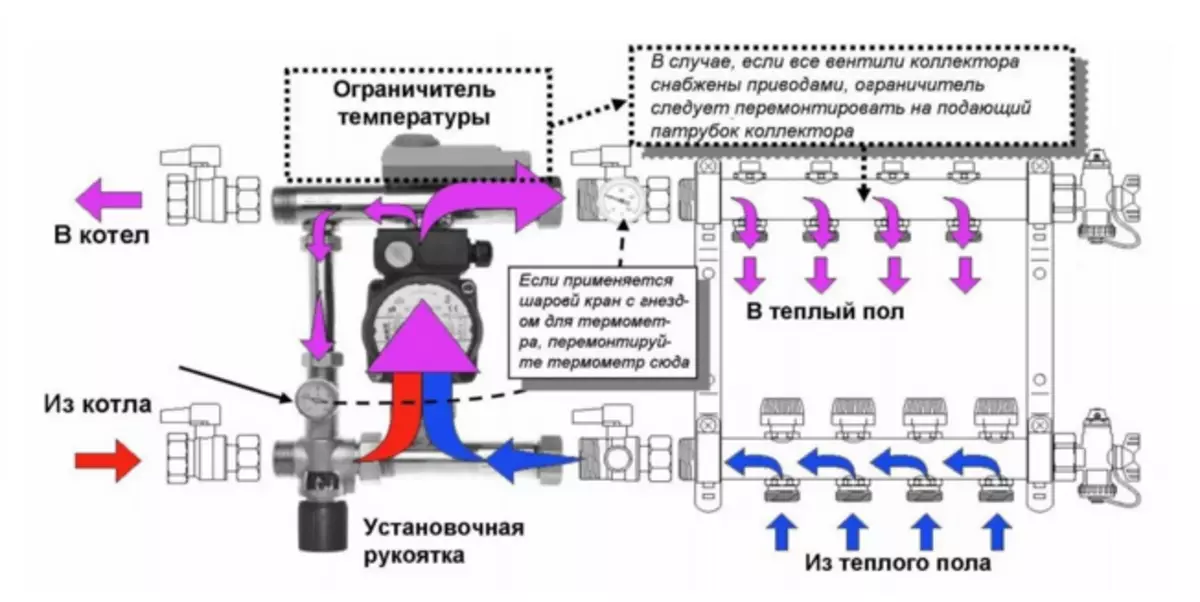

The distribution unit is necessary for mixing hot and cooled water - it is very simple, but, in fact, the correct definition of the task of the device. This equipment will allow regulating the temperature of the coolant, respectively, to evenly distribute heat indoors. The collector contributes to more efficient consumption of energy resources, due to which the owner's funds are saved.

Article on the topic: What varnish can cover the wallpaper of various species

The distribution unit, the collector, is often accompanied not only by installing the comb, but also an air vent, drainage crane. These additional elements will prevent air accumulation, which is important in the heating system. Installing the collector and its components will allow to turn off heat carriers in certain areas when necessary. In other words, the distribution unit is the heart of a warm water floor.

Components of the distribution unit

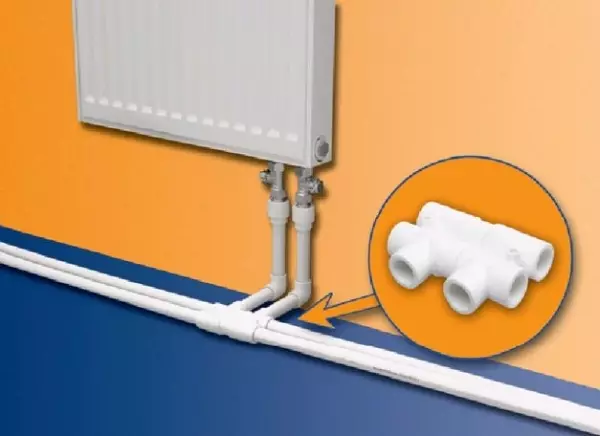

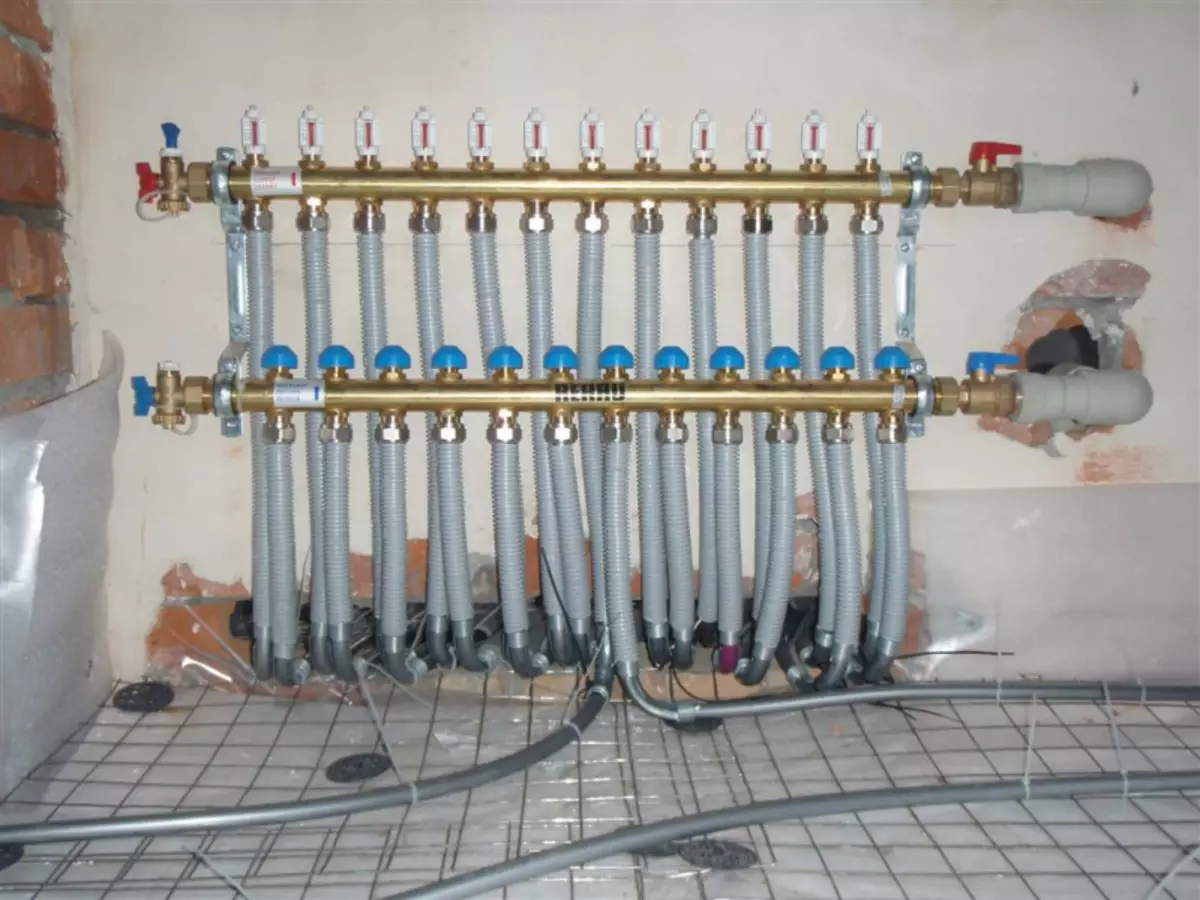

Collector equipment is the collection of parts required for the functioning system. First of all, you need to take a special place for the collector cabinet. It is usually in the middle of all contours, that is, you need to install the box so that all heaters are equal to removal from it. A wardrobe is installed, a metal box, and feed pipes and return pipes are mounted.

Feed is hot water coming from the boiler. The return is the cooled water coming from the pipes of the warm floor. Special shut-off valve is installed on these elements - valve. This is done with the help of fasteners called fitting. The shut-off device is necessary so that water can be overlap if necessary.

Next, the collector itself is connected, consisting of two combs, aircraft, drain crane, thermal sensor and valves. This classic diagram of the component of the collector node can be complemented by automatic and other electronic sensors.

Mounting collector

You can assemble the distribution unit yourself. First of all, you should decide on the location of the collector cabinet, as already mentioned above. The design itself is usually hiding in the recesses - niches. They can close or stay open to whom is more convenient.

As soon as the stage of establishing the supply and reversal pipes is finished, they are fixed to the collector component. This is a metal element with branches and output from the opposite side. Typically, this output is closed with a plug, and the air vent is installed at the top. Next, the pipes of water floor contours and are attached to the manifold system fittings.

Article on the topic: Heated by the pool with their own hands

It is important to understand that the length of the coolants should be more or less the same, otherwise the efficiency of the system will suffer. If one contour is much superior to another one, you will have to install a separate thermal sensor and pumping equipment on their outputs.

The assembly of the node implies the installation of three-way valves responsible for mixing coolants. In order for temperature adjustment to occur automatically, set special sensors. The principle of their work is quite simple. When the threshold is reached, the set temperature, the valves are installed close the coolant. In this way, adjustment is carried out.

Collector Connection Scheme with Automation Elements

Of course, the possibility of installing a certain temperature and, accordingly, the efficient operation of the system involves collecting a very complex manifold. It will include groups of automation and electronics, which complicates the installation process and beats the pocket.

However, the result from automated equipment will delight the possibility of further savings on heating. If you want to pull only one room, you can buy the easiest and easy-to-install collector node. The disadvantage of such a device is its inability to adjust the temperature. Otherwise, collect a collector for a warm floor with your own hands possible.

Types of distribution node

Of great importance is the form of a collector system. It depends on the number of contours, construction design and budget. It is customary to share complex mechanisms and simple. The latter are installed for one, the maximum of two contours. They are easy to install and consist of the necessary elements responsible for mixing coolants.

Complex mechanisms are equipped with automation and electronics. They are designed to maintain several contours and imply the temperature control of the working fluid.

It is also important of the material from which the collector is manufactured. The most popular and distributed are the following materials:

- Brass installations are in great demand, despite their considerable cost. This is explained by the fact that brass has such characteristics as durability, reliability and ability to withstand high pressure. Such a mechanism is suitable for all types of pipes.

- Copper equipment is known for its ability to withstand the highest temperatures and pressure. If the brass holds pressure up to 14 atmospheres, then copper is up to 30 bar. This characteristic allows the use of a copper collector for coolants, where not water is not as a working fluid, but oil.

- Collective stainless steel assemblies are most often applied, as they have a democratic pricing policy and positive characteristics. The collector for the warm floor of the stainless steel is the best and right solution.

Article on the topic: Waterproofs from sewer pipes with their own hands: how to make water

The installation of the distribution node depends on the number of contours, the type of room and, of course, the owner's budget. The assembly of the collector does not represent anything complicated. The main thing is to correctly calculate the temperature of the floor and establish all the necessary and important elements of the mechanism.