The construction of a log house provides for the use of various technologies. The log house can be erected from a chopped log (ostened manually) or from a cut, circulating on a special machine.

The log house can be built from a chopped log or from a cut, rounded on a special machine.

Wood selection rules

For the construction of a wooden house, various technologies apply with their own hands. Modern methods of construction allow you to process a log house to the desired form, cutting into the grooves in the logs for subsequent fixation in the crowns. Each size is adjusted up to 1 mm. The construction of the house (for this technique) is represented as a designer assembly. When conducting such work, you will need to make a drawing.

If the house is erected from the rounded log, then pre-removed the bark and the upper layers, including the swamp. The next stage provides wood processing with special impregnations. The diameter of each element should be more than 300 mm. The project, on the basis of which the construction of a log house is made, you can buy in the finished form or perform yourself.

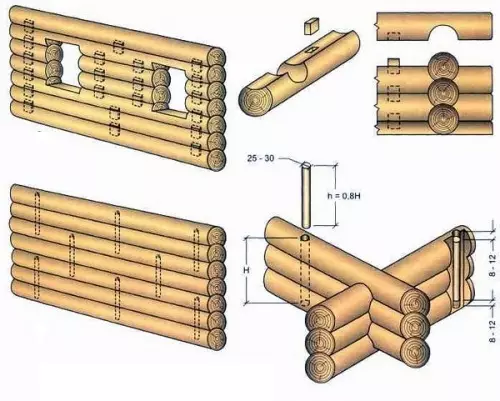

Circuit assembly scheme from a rounded log.

The price of such a building depends on the following criteria:

- Floors;

- material;

- The complexity of the design.

The walls of the object can be adjusted to each other at different angles. This is due to the fact that in the logs you can cut the bowl of the desired form. Builders allocate 2 methods of building at home:

- Breasting logs at the construction site;

- Building a building according to a drawing with the help of pre-prepared rollingwood.

For the 1st method, the use of natural moisture forest is characterized. When choosing a material, its density is taken into account. The logs must have a yellow or dark yellow surface. The slice should be smooth and dense, without resin pockets. A crack in the wood can have a depth of no more than 1/3 cut.

Article on the topic: How to install a Chinese metal door: features

Preparatory work

For independent construction of a log house, you will need to buy beams, rafters, lags, roofing material, roulette, level, buckets, boards, self-tapping screws, screwdriver. Then the plot is prepared for the future structure. Wood needs to be stored under a canopy. Since the builded building has a minor weight, it will take a small-breed foundation for him. For these purposes, experts advise to fill the pile and ribbon base, slab, pile or a bellged belt design.

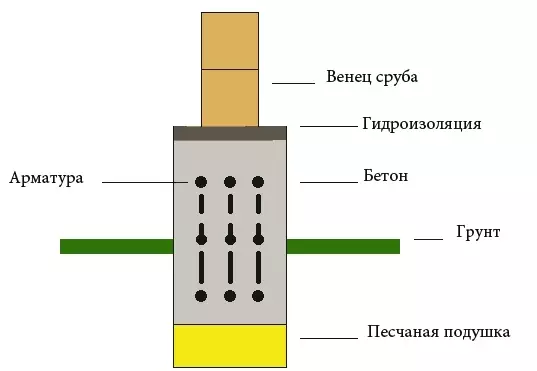

Foundation scheme under a log house.

To arrange a pile-belt foundation, you will need to place a plot. Then the upper layer of the Earth is removed. The width of the structure takes place with a depth of 30 cm. On the perimeter of the building, the wells are equipped, the diameter of which is 180 mm, and the depth is 150 cm. In each well, a layer of rubble and sand is poured into each well. From the reinforcement prepared the framework, which is lowered into the well. The next stage provides for pouring pit with concrete. A vibrator is used for the rambling.

For arrangement formwork use boards. The design is mounted above the ground level so that it performs 50-60 cm. For a tape base, a frame will be welded, which binds to the reinforcement sticking out of wells. The next stage provides for the fill of the base. If the foundation hardened, then its waterproofing is produced. To do this, it will be necessary to put on the surface of the rubberoid (3-4 layers), additionally, labeled the material by mastic.

Rules of construction of walls

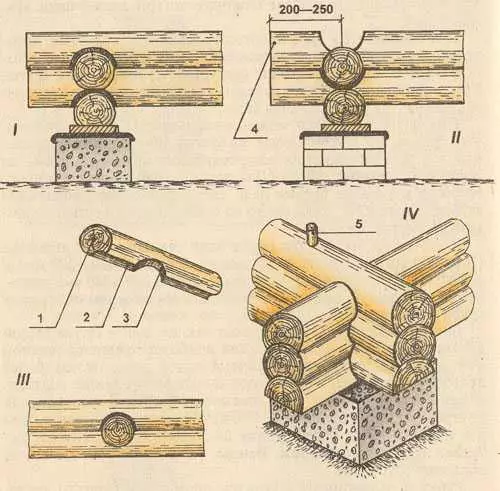

The mortgage (1st) crown can not be mounted on the base of the log house. Pre-for the foundation laid the board (from the linden). To do this, it is possible to use a timber, the thickness of which ranges from 50-100 mm, and the width is no more than 150 mm. The next stage provides for a grazing assembly.

Scheme of the construction of walls from logs: i - cutting a cup down; II - cutting up a cup; Iii - proper laying of logs with a cup; IV - cutting corner; 1 - processed log; 2 - groove; 3 - cup; 4 - residue; 5 - Agel (spike).

Article on the topic: Interiors of American apartments: Acquaintance with how they live in America (42 photos)

Initially logs (1-2 pieces) laid on opposite wall walls (parallel to each other). Each log is provided by the factory longitudinal and castle angular connection. The next stage provides for the styling of the forest to the remaining 2 sides. Top put insulation. The grooves and grooves are filled with moss, pacles, jute and other material for cacopa. The insulation is placed in such a way that it hangs from all sides by 5-6 cm. Building stapler is used to fix it. Since the jute tape completely covers the groove, and in the cup in the middle, in the last element, the material is installed with 2 segments. Reception is filled with insulation.

2 logs are mounted on the transverse sides of the foundation. They rely on the mortgage crown. Between the wood you need to observe an angle of 90 degrees. Builders advise regularly control their horizontality. The remaining crowns are installed in a similar scheme. Some modern technology for the construction of a log house provide for the use of brazing (for fixing the crowns).

The elements under consideration are presented in the form of wooden plates made of dense wood. In each log, you need to make a hole in which the bell is inserted. The remaining 2 crowns are not fixed (for shrinkage). In factory-cylindered logs, holes under the door and window openings are provided.

Installation of roof

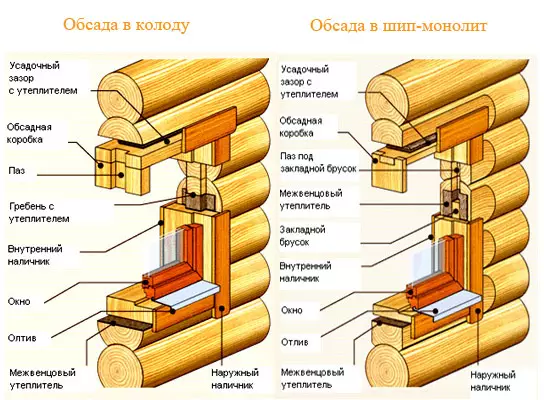

Installing windows in a log house.

The next stage provides for the installation of the roof. The beams and rafters are included. Recent elements are mounted on the logs of the upper crown. If desired, Maurylalat is pre-laid. If a veranda is provided in the project, then the shrinkage compensators are inserted into the support (vertical location). To prevent the breakdown of the structure, each vertical log is equipped with the latest elements.

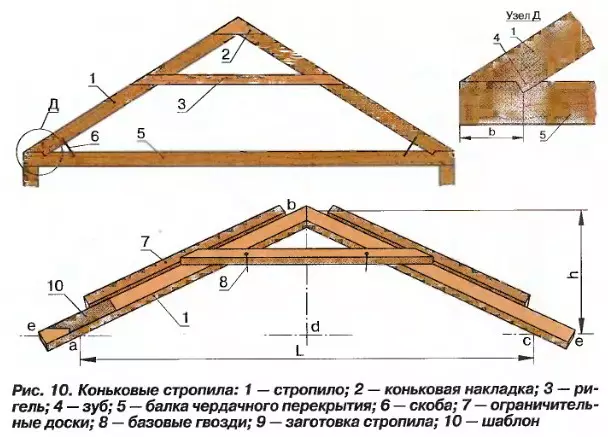

Metal studs are used for connecting skate analogs. The rafters are mounted in a step of 600 mm. This will require a bar with a cross section of 50x200 mm. For fixing the design to the last crown use sliding supports. The waterproofing material is laid on top. When installing the crates, a step is observed, which depends on the type of roofing used. The next step provides for the roof installation.

Article on the topic: Linoleum laying technology and the production of linoleum plinth

Upon completion of the installation of the roof, the insulation will be needed. This will require a special tool. The material wrap up 5-6 cm down, pushing in the gap between the crowns. In this state, the house is left for a year (for its shrinkage). After the specified time, the process of the cacopa is repeated. Educated gaps close up with jute or hemp.

Installation of the roof of a log house.

Some builders are recommended to carry out a root of the building after its annual operation. An important point in the construction of a log house is to install doors and windows. Partitions and openings are mounted a year after the construction of the building. Pre-put casing boxes with special fasteners. Windows and doors are inserted into the resulting design. Since wood should be expanding and pissing, the process in question occupies a long period of time.

The construction of the floor of the log house provides for the insertion of the lag into a mortgage or subsequent crown. Recent elements must be securely secured. The mortgage crown needs good ventilation. Specialists recommend mounting the floor covering on the lags of the upper crown. In this stage, the installation of various communications is carried out, including the heating system, plinths, plumbing.

If the construction of the house is made from the logs of insufficient length, then their docking is allowed.