Photovideo

A few years ago appeared and quickly deserved good fame a universal material - polycarbonate. It is very strong and flexible, translucent and diverse in color shades, very light weight and easy to install. These qualities allow it to apply it for the construction of greenhouses and greenhouses, use it in advertising and mechanical engineering.

The properties of the material allow to construct a light and durable roof for the veranda, houses, garage, greenhouses, arbors and other premises.

The polycarbonate is very strong and flexible, translucent and varied in color shades, very light weight and easy to install.

The roof of polycarbonate is erected with its own hands simple enough, allows the room as lighting the natural sunlight.

Characteristic

Cellular polycarbonate - polymeric material. Inside it has many small aircases, thanks to which good sound and thermal insulation is ensured. It is well cut, dried, bends, gluits. Such a roof does not give to accumulate on its surface in the snow and water.

Polycarbonate is available in different thickness - from 4 to 16 millimeters. Especially if you consider all its advantages, positive properties and affordable price.

Polycarbonate is produced in the form of sheets with a thickness of 4 to 32 mm. The standard width of such a sheet is 2100 mm, length is 6000 mm, sometimes 12,000 mm. Lists of 4-6 mm thick are designed for the manufacture of advertising shields, signs and inscriptions. For construction purposes, polycarbonate is used with a thickness of 8-16 mm. 20 mm thick sheets and more applied rarely. According to the quality of the material and the service life, it is divided into categories. The category "Premium" has a guaranteed service life for more than 20 years. The class "elite" is at least 12 years. The class "Optimal" is designed for use for up to 10 years. The cheapest "economical" is up to 8 years.

Article on the topic: Window Cake in the interior of the kitchen, living room, bedrooms: Schemes (photos and video)

Main advantages:

- Light permeability of more than 90%;

- lighter glass 15 times;

- Does not miss ultraviolet rays;

- High impact resistance;

- resistance to temperatures from -50 to + 20 ° C;

- It does not crack in the cold;

- Does not highlight toxins in the heat;

- The average service life is more than 12 years;

- Easy processing and assembly.

Methods of fastening

The main types of installation there are two: wet and dry.The wet method involves the use of a polymer smelting, which is applied throughout the perimeter of the frame. The sheet is stacked on a layer of putty and tightly pressed to the base. Mazzka can be replaced by elastic rubber gaskets. The sheet is attached at the corners or long sides. The joints are additionally close to silicone sealant and for decoration with wooden or plastic corner. This method is infrequently used. The dry method is used more often. It has greater purity and accuracy. All compounds in this method occur with the help of self-samples, bolts, screws, nuts.

Installation of roof

A number of requirements are presented to the roof design:

To connect polycarbonate panels, various types of profiles are used, which are selected depending on the design.

- The roof mounted from polycarbonate should provide a certain level of illumination;

- must protect the work areas of the room from direct sunlight;

- The roof must have ventilation;

- Snow from the roof should be removed in a timely manner and without much difficulty;

- The roof must have a solid design;

- Mandatory sound insulation, thermal insulation, vaporizolation and waterproofing.

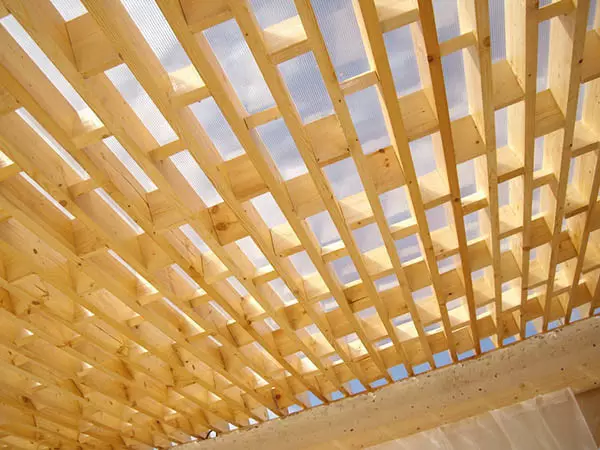

The roof is mounted on structures from special profiles. Profiles are made of steel and aluminum. Steel applied when building large spans, aluminum - for the spans of medium and small sizes. There are profiles for pitched roofs.

To secure sheets to the framework of profiles, special self-tapping screws are used with washers. They are raised after 30-40 cm. There are special polycarbonate fastening profiles and plugs for the end parts of the sheet. The plugs prevent dust and insects in the leaf air chambers.

Article on the topic: Use of wallpaper in the interior

Materials and tools

- sheets;

- profiles;

- Silicone sealant;

- Self-tapping screws with washers;

- drill;

- screwdriver;

- Knife, saw-knife or disk saw.

Main steps

How to make a roof of polycarbonate, you need to consider whether the sheets are produced with a width of 210 cm, and it is necessary to put the rafter beams so that the sheets of sheets are in the middle of the rafter.

The roof of polycarbonate, like any other types of roofing for the house, requires the preliminary erection of the rafter system. Slinged beams under the roof must be installed so that the sheets of sheets accounted for the middle of the rafter. Slingers can serve as brus of a tree with a cross section of at least 40x60 mm. The distance between the axes of the neighboring rafters should be 1.01 m. The rafters are mounted with a frame of steel, aluminum or polycarbonate. More easily for these purposes, wooden bars of 30x40 or 40x50 mm and a boards of about 60 mm wide and a thickness of 30 mm are used. Separate elements of the frame are brought to the rafyles by self-drawing. Polycarbonate is chosen in thickness from such a calculation:

- For large openings on industrial buildings, sheets 32 and 16 mm thick are used. Such a roof is suitable for roofs of gas stations, carports in parking lots, bus stations;

- 4 mm thickness is suitable for roofs of greenhouses and greenhouses;

- For the construction of the roof for the house it is quite suitable for a thickness of 8-12 mm;

- Color can be any. The lighter, the higher the light-permeability of the material.

All seams are sealed with silicone sealant, with a length of polycarbonate sheets, equal to the roof slope, there is no need to seal joints.

Polycarbonate sheets are stacked by a protective film with the inscription upwards. The frame is fastened with self-assembly with thermocomptation washers. The pitch of the screws is about 30 cm. Pre-in polycarbonate, a hole with a diameter of about 2 mm is drilled more than the diameter of the self-press. Self-tapping screws are not tightened until it stops. The sheet should be able to move with temperature drops. Fastening the collapsible profile begins with the attachment of its lower part. Then the edge of the sheet is inserted into it and only after that the upper part of the collapsible profile is attached. All seams are sealed with silicone sealant. With the length of sheets equal to the roof slope, there is no need to seal joints. The sealant is used only to handle joints between adjacent sheets. When using polycarbonate frame elements and this necessity disappears, as the joints are closed with special linings providing tightness. The protective film with the inscription is removed with the roof assembled from the polycarbonate last.

Article on the topic: The ceiling of plastic panels do it yourself - instructions (photo and video)

When erecting the roof of the arched construction, the installation of the crate is not required. It is enough only for greater strength to combine arched structures. Cut or drill a sheet better on a flat flat surface, without removing the protective film from it. Tools are the same as for wood processing and plastic.

So that the roof of the polycarbonate serve for a long time, you need to clean it from dust and dirt. This is done with a sponge impregnated with soap solution. The use of sharp objects, abrasive and caustic substances is unacceptable.

Of particular difficulties in the installation of the roof of polycarbonate. Good luck in job!

Load more