Using the NPP panels for walls is one of the most sought-after ways to finish the vertical surface. Genuine wood perfectly retains heat, has the properties of sound insulation. In the cold season, the product does not allow the walls and maintains the optimal level of humidity.

Warm panels are the best material for the trim. For vertical vertical surfaces, the flat panels are usually used.

Advantages and disadvantages of fiberboard

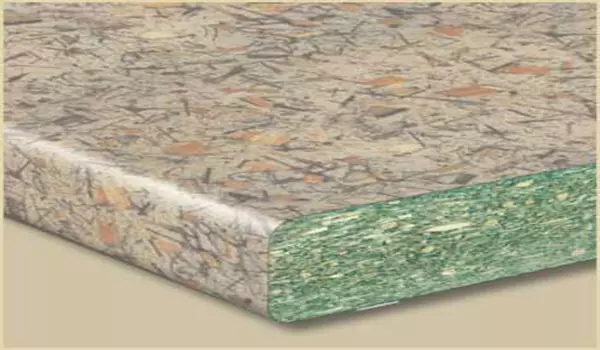

The advantages and disadvantages of fibreboard depend on its hardness. The hardness is determined by the purpose of exploitation of the material. Today manufacturers offer soft, semi-solid, solid and superhard plates. The latter are used in the process of construction and making carrier furniture structures.

Benefits:

- Fiberboard (organite) is manufactured by pressing wood fibers under the influence of high temperatures. It is durable, protected from swelling, resistant to ignition material.

- Fiberboard is a flat product. It is made by drying, pressing, using the binder substance. On top of the Fiberboard, the wood layer is usually spruce or pine. In order to underline the natural wood pattern and imparting the decorative surface, it is performed by its varnishing or covered with an artificial patina. Sometimes the processing of the veneer or tinting agent is performed. Decor panels with thread and modeling. All these technologies allow you to make panels more presentable.

- Plates come in different shapes and sizes. There are a large number of shades: from gently beige to red, purple. Products collected through unconventional methods are very effectively looking, for example, using mirrors.

- Warflake plates have excellent moisture resistance. Due to which this material is often used to finish bathrooms.

- The surface is easily cleaned with a wet rag. It is not desirable to wet strongly, and even more so wash the panel with powder.

- Another advantage of the wall cladding with wooden panels is that the walls do not necessarily leveal. The basic condition - the surface should be dry. This will reduce the time of cladding.

Article on the topic: Installing the entrance door in a wooden house

- Low price Fiberboard makes this material one of the most popular on the construction market.

- Proper operation of the product ensures its strength, durability.

- The material is easy to handle without changing its structure.

- The laminated product is used in the manufacture of furniture.

The only disadvantage of DVP is a small thickness of the sheet, which limits the scope of application of this material.

However, the scope of its use is not limited to construction, but applies to the production of furniture, automotive, car building, carpentry production.

Proper preparation - the key to success

Each job must be pre-planned to avoid excess spending time, strength and cash.

- Think up how much money you can spend on the purchase of materials. This first point and will be decisive in the choice of a variant of the decorative wall decoration.

- Perform the drawing of the room or make a photocopy of a floor plan. This will help calculate the required amount of material. At the same time, it is not necessary to move all the ceilings, floors and walls.

- Analyze the market of manufacturing companies and prices for their products. This will help make the right choice. You can find various interesting options. For example, certain models or discount on the balance of quality goods.

- Calculate the number of required material. In order to calculate the area of the facing product, you must multiply the length of the length, take the area of windows, doors and add 10% to fit.

- Purchase wholesale is usually cheaper than retail. In this case, additional savings on the transportation of goods will be released. Often building firms - manufacturers offer free shipping for the purchase wholesale.

- Prepare all the necessary tools. To save money, they can be rented.

- If the walls are separated by wooden panels to order, the plates are manufactured strictly by the parameters of the room. This allows the use of all purchased products without waste.

Installation of panels

Distribution panels can be attached to clamps, nails or mastic. Work does not require special knowledge and skills, so it can be done with your own hands. Before starting it, it is necessary to unpack the material and leave it at room temperature for a day. It must adapt to the humidity in the room. If the walls are very uneven, then you need to bore them and align.

- One of the popular methods of installation is the use of special lock fixators. During production, the panel is equipped with fixing details on end and lateral planes. This method allows you to quickly perform an assembly due to fixing the bottom of the holes and pins. From above, the plate is fastened with lock locks with cams and cutouts. These parts allow you to maximize the position of the Fiberboard of the panel. They also do not require corrosion protection.

- The frame for the Fiberboard can be attached to nails. The first board is mounted from the angle with the front side. To frame a wooden panel is mounted with nails. All subsequent tightly bonded together and must be docked in the groove. Then the surface finishing with decorative elements is performed.

Article on the topic: How to cut a loop in the interroom yourself?

- Most often in repair, the fastening of wooden panels is found using mastic (adhesive composition). But provided that the walls are perfectly smooth. The adhesive substance should be thick and plastic. It must be evenly applied to the wall with a toothed spatula with a thickness of several millimeters. Then tightly press each panel. Which of the installation methods to choose is to solve you, and it is better to consult with a specialist. The walls of the walls of the Fiber Plays is easily. You only need to make a little effort.

Useful advice

- Regardless of the place of the attachment, process the timber for the crate with high-quality soil. This will increase the operational period of the entire design.

- Cover the panels in the lock system, which will create a beautiful decorative look.

- Close the joints with decorative inserts.

- Wall panels combine with wallpaper or decorative stucco. This will bring novelty and varieties to any interior. Thus, the appearance of the room can be changed if desired. At the same time, financial investments will be minimal. It is enough just to replace the wallpaper or repaint the wall.

- The fastening of the parobacker under the crate will help to avoid the occurrence of condensate on the walls.

- The parobararier is a film that protects against the formation of condensate.

- A certain batch of goods must be purchased at the same time from one manufacturer. Because different manufacturers apply their own technology. As a result, the properties and the composition of the material with the same name in different firms may differ.

- It is convenient to use an electrolovka for cutting the arches and other elements.

Video "Installation of MDF panels on the wall"

Look at the video on the installation of the panels under the tree, its installation is similar, with the installation of the chipboard, only with small differences.