The scope of reinforced concrete rings is quite extensive. If there is a need to save, they can be made with their own hands. But this requires forms for concrete rings. Buying such equipment - expensive pleasure, for private use, it will not justify itself. But the forms can also be made independently.

What are concrete rings

Most often, concrete rings are needed for the well device, but they are also used in the device of autonomous sewage - they make septic tanks or filtration wells. Another area of application - viewing wells in the device of a storm and drainage system. Make even cellar from concrete rings. And there are different options - vertical, horizontal. In general, the scope of application wide.

Concrete rings are used to build various structures

There are rings of different sizes for different needs, they also have different wall thickness, can be reinforced or without. Despite such an abundance of choice, many are thinking about making reinforced concrete rings with their own hands. The thing is that during the arrangement of the site may need not one ring, and not even ten. Some only on the well goes more than a dozen. The cost of manufacturing reinforced concrete products is much lower than their retail price. Even taking into account the fact that we will have to make forms for concrete rings. And if you still consider the cost of delivery, then the savings are obtained very solid.

Varieties and sizes of concrete rings for wells

Industrially made concrete and reinforced concrete rings must be responsible for the standards prescribed in GOST 8020-90. Their sizes can be taken from the table, as well as approximate weight and price (indicated, taking into account the delivery in Moscow).

| Name | Height | Wall thickness | Inner diameter | Weight | Price without lock / with lock |

|---|---|---|---|---|---|

| KS-6. | 7 cm | 12 cm | 58 cm | 60 kg | 390 rubles |

| KS-7-1 | 10 cm | 8 cm | 70 cm | 46 kg | 339 rubles |

| KS-7-1.5 | 15 cm | 8 cm | 70 cm | 68 kg | 349 rubles |

| KS-7-3. | 35 cm | 8 cm | 70 cm | 140 kg | 589 rubles |

| KS-7-5 | 50 cm | 8 cm | 70 cm | 230 kg | 800 rubles |

| KS-7-6. | 60 cm | 10 cm | 70 cm | 250 kg | 830 rubles |

| KS-7-9 | 90 cm | 8 cm | 70 cm | 410 kg | 1230 rubles |

| KS-7-10. | 100 cm | 8 cm | 70 cm | 457 kg | 1280 rubles |

| KS-10-5 | 50 cm | 8 cm | 100 cm | 320 kg | 1110 rub |

| KS-10-6 | 60 cm | 8 cm | 100 cm | 340 kg | 1130 rub |

| KS-10-9 | 90 cm | 8 cm | 100 cm | 640 kg | 1530 rub / 1700 rubles |

| KS-12-10. | 100 cm | 8 cm | 120 cm | 1050 kg | 2120 rubles |

| KS-15-6 | 60 cm | 9 cm | 150 cm | 900 kg | 2060 rub |

| KS-15-9 | 90 cm | 9 cm | 150 cm | 1350 kg | 2670 rub |

| KS-20-6. | 60 cm | 10 cm | 200 cm | 1550 kg | 3350 rubles |

| KS-20-9 | 90 cm | 10 cm | 200 cm | 2300 kg | 4010 rubles |

| KS-25-9 | 90 cm | 12 cm | 250 cm | 2200 kg | 16100 rubles |

Article on the topic: Registration of the headboard in the bedroom cloth, wallpaper and other hand (photo)

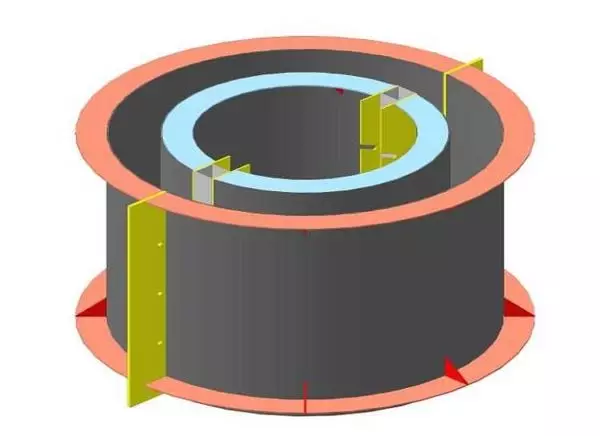

For the manufacture of products of each type, two parts of the formwork should be external and internal. The distance between them is registered in Guest depends on the size of the ring. For reinforced rings for a well with a diameter of 70 cm or 100 cm it is 7 cm and 8 cm, respectively, when making a rings without laying fittings, the wall thickness is much larger - 12 cm and 14 cm.

For the manufacture of w rings require special forms

In addition to different sizes there is another different profile of the end of the rings - even and with the lock. The castle is a protrusion protrusion protrusion. Call such rings with puzzle or castle. They put on each other. They are well connected, it is difficult to move to lateral loads, which is very important when the wells device of any destination. The minus of this option is more complex forms for concrete rings - it is necessary to form the corresponding steps in the ends.

Technology of manufacturing concrete and reinforced concrete well rings

For the manufacture of concrete rings in production, a hard solution with a small amount of water is used, after the fill it is necessarily subjected to vibration. Without this process, it is impossible to achieve homogeneity and high strength. At the production, the vibrators are embedded in the walls of the forms, with private manufacture, you can use the submersible vibrators for concrete. These are relatively small devices whose housing is held in their hands, and the vibrobulva is lowered into the concrete. The length of this nozzle should be sufficient to get almost to the bottom of the ring.

So looks like a submersible vibrator for concrete in work

What concrete use

Concrete for well rings for tensile strength is not lower than B15 (class M200). The composition of the hard concrete, which is used in production:

- Cement PC500D0 - 230 kg:

- Sand of medium grain (dimension module 1.5-2.3) - 900 kg;

- Crushed stone fraction 5-10 mm - 1100 kg;

- C-3 plasticizer - 1.6 kg;

- Water - 120 liters.

The output is a cubic meter of concrete. The amount of water is indicated for sand humidity 4%. If the sand is wet, the amount of water is significantly reduced.

How can a form for the production of concrete rings

What I must say that in the usual household concrete mixer type "pear" such a dry concrete you do not mix. For the knead it is necessary to use a mixer of forced type. If it is not, make a more fluent concrete. The lack of such a solution - it is necessary to withstand concrete in the formwork for some time (from 4 to 7 days depending on temperature). If there is one form for concrete rings, the manufacture of a dozen concrete rings can stretch for months. Exit - to make the solution so hard as possible and not one pair of formwork.

Reinforcement of concrete rings

You can link the reinforcing ring from the ribbed rod with a thickness of 8-10 mm - circle, interconnected by vertical sections of reinforcement. The number of armature rings depends on the height of the ring. The optimal distance between them is 20-30 cm. With a height of the well ring, 90-100 cm make three or four reinforcement belts. Vertical segments are installed in a step of 30-40 cm. They are tied with a special knitting wire.

You can bind a loop to the upper belief of the reinforcement, for which the concrete ring can be conntive with the help of lifting equipment.

An example of reinforced concrete ring

Article on the topic: What are the curtains from natural tissues

When installing the reinforcing belt, remember one item: the valve should be located in the thickness of the concrete. From metal to the edge of the product should be at least 3-4 cm. Therefore, in the figure above, it is shown that the reinforcement belts are not on the surface, but significantly lower. It is necessary to place the reinforcement.

The reinforcement can be welded, but better - to connect - the design is more durable

Homemade concrete rings are more often reinforced by a finished steel mesh - a rod thickness of at least 4 mm, step 20 cm. It is cut off with a tedious height and length, bend into the ring, the edges are linked to the wire. Such reinforcement is somewhat worse than the standard, but it is enough to give greater strength.

What gives vibration

The process of the vibration increases concrete strength into several classes (without changing the formulation). When processing concrete, it in front of the "sit" from it exits air bubbles, the aggregate and cement is more evenly distributed. It will not work without this procedure - the walls will be loose, will flow and quickly destroy.

Smooth and dense walls can only be obtained if concrete vibrate

However, it is impossible to overdo it - bundle may occur. Stop processing when the shrinkage of the solution is stopped, the surface will become smooth and cement milk will appear on top.

Manufacturing process

Outdoor (external) part of the formwork is installed on a flat or iron sheet of iron. If a puzzle ring is made, the groin shaper is stacked. A reinforcing grid is exhibited from the edge of the formwork at a distance of 3-4 cm. The inside of the formwork is set, it is fixed with the helns to the protruding parts of the external formwork (fingers).In the established shape of shovels or some device, concrete is thrown out. After the ring is filled, vibration is carried out (in finished forms it takes 1-2 minutes). If necessary (watching the shrinkage), the concrete is added. After the end of the vibration, the surface of the ring is loaded with a trowel. If necessary, install and pressed the ridge ring.

In industrial environments, the spell is immediately carried out - for this, the hard concrete is used so that you can immediately use the set for the manufacture of the next ring. To do this, remove your fingers, remove the formwork. Forming the lower groove of the hollow formator remains until concrete setting.

How and from what to make forms for concrete rings

Factory forms are made from sheet metal, enhanced rigidity ribs. Metal thickness - 3-8 mm depending on the size of the ring.

Forms for well rings most often make metal

From barrels with thick walls

At home, the leaf metal with the desired radius of curvature is not easy. It is much easier to find two thick-walled barrels with different diameters. The diameters should differ by 14-16 mm. In this case, the wall thickness will be 7-8 mm. For a well ring with reinforcement - what is required.

To easier it was with a form for reinforced concrete rings to work, you can twist two halves to the door loops

The barrels cut down the bottom, the inner part is made above about 10 cm - it is more convenient. To remove the formwork from the finished rings, the barrels are cut along into two parts. Halves need to be securely connected. You can do this in different ways:

- welding a corner with drilled holes, pull bolts;

- Make "ears" in which wedges score.

So that the inner part does not behave, each half the half must be accessed by several struts that will hold the walls from curvature.

Article on the topic: Embroidery by a cross for beginners by finished drawing: in terms of cells of the scheme, Matrenin Posad, applying for children

By inserting one part of the formwork to another, put them at the same distance alone relative to the other (measuring the gap in a circle). In several places, drill holes - under the studs that they will be fixed. Studs - the segments of the rod from both sides of which the thread is sliced. The holes are placed one opposite the other so that you can safely fix the part of the formwork.

Inside the drilled holes insert studs, tighten with nuts. With a very large thickness of the walls of the shape for concrete rings, most likely, you will have to put the large washers or carved plates with a hole under the nuts - so that when the concrete is pouring the form, the form has not begun.

From sheet metal

If you wish, you can make forms for concrete rings and from the sheet metal strip and wooden bars that will attach rigidity to formwork. Cut the strip of the desired length - along the length of the circle + 10 cm on the connection. The width of the strip is equal to the height of the ring + 10 cm. Below and at the top bend the sides of 5 cm, along the edge of the band you do the same side. In the side side drill holes for tightening bolts. Top side cut every 20-25 cm (less if the diameter of the ring is small). Now the strip can be bent - get a ring. But it is very unstable - "plays." Stiffness can be given using a wooden frame.

Molds for concrete rings can be made of sheet steel

From the bar cut the pieces of 20-25 cm long. Clepping them under the side drill the hole in the metal, screw the segments of bars on the screws. With a length of bars in 20-25 cm, the form will not be round, but multifaceted. If it is critical for you, you can make cuts more often, in short to drink bars. Strengthen also needed height. For this, also use bars. It is necessary to attach them more often - so that the walls do not begged.

If you know how to use welding, you can go to another way. In addition to sheet metal, a profiled pipe of a square section will be needed. Makes 15 * 15 mm or 20 * 20 mm. First, you need to bend four identical seven-step from the profile pipe. Four large - for outdoor formwork and four smaller - for the inner. To the arcs to welcome the carved metal stripes.

As the basis for using arcs from the profile pipe

From wooden boards or bars

If you work easier with a tree, you can collect forms for the GB rings from wood. They are collected from non-strokes, downstairs and at the top are fixed with the ring. The ring can be made of metal, for example, from a bent profiled tube. Its on the pipe bender can be reached with the desired radius of curvature.

Forms for the production of rings can be made of wood

If the coolest art is your horse, you can make arcs too from wood. The material is not so important. The strength and rigidity of the obtained form is important. Please note that the side is fastened from the outside of a larger formwork and from the inside the smaller.

Important! To remove the formwork easily, it is necessary to lubricate before the fill. If you plan to use concrete rings for a well with drinking water, you can use sunflower oil. If some technical structure is assumed, you can use the use of machinery mixed with machinery or with DT (or pure machine oil) as lubrication.