The filling technology of bulk gender using polymer self-leveling compositions allows you to form a perfectly even and durable finish coating. The material is used and when the draft floor is applied. The fluidity of the mixtures of this type reduces the complexity of the preparation of the basic base for further finishing of the surface.

The device of polymer bulk floors.

Choosing a liquid mixture and tool preparation

Bulk mixtures differ in the type of main component. Polyurethane, epoxy, acrylic, epoxy-urethane compositions are used for the liquidate device. Thanks to the distinctive operational properties, the first two types are most common.

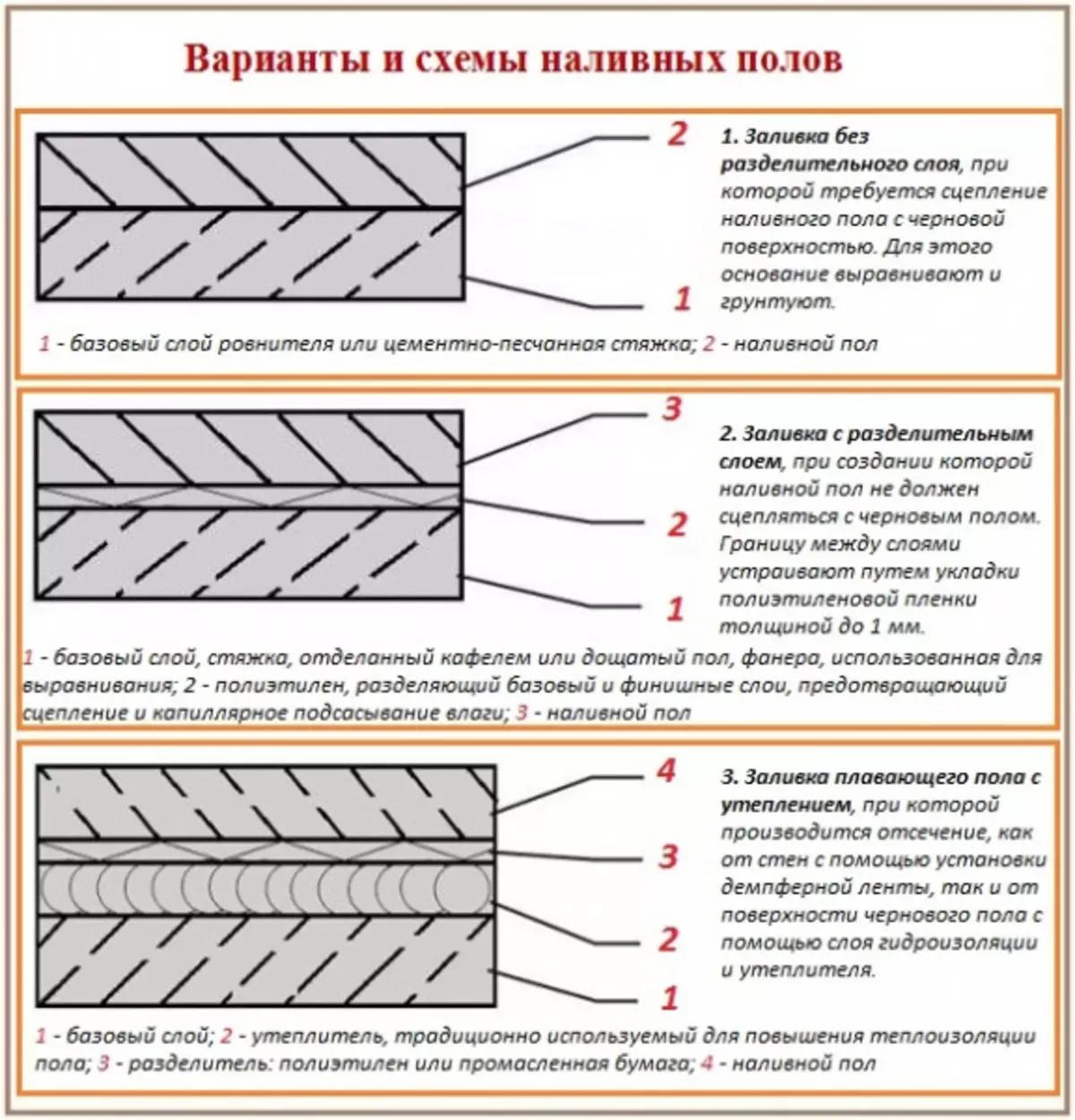

Options and schemes of bulk floors.

To ensure the sound operation of a liquid coating during the period-guaranteed period manufacturers (up to 40 years), it is necessary to choose a material corresponding to the properties of the base and other conditions of the room.

Epoxy liquid coatings have resistance to mechanical effects and aggressiveness of chemicals. Therefore, they are more often used for floors of floors in public halls and industrial premises.

Polyurethane base floors have the same distinctive characteristics as epoxy, but more elastic and cheaper at cost. Methyl methacrylate coating type is resistant to temperature fluctuations and most environmentally friendly.

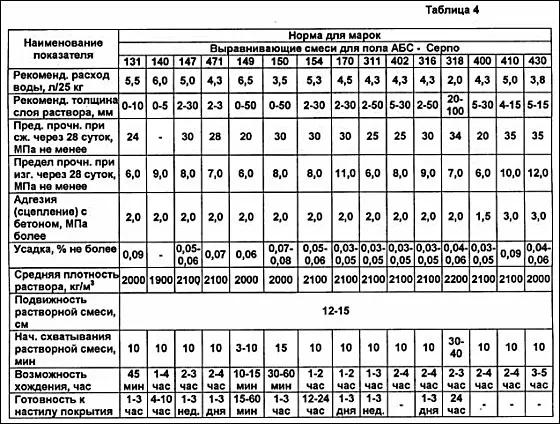

Some mixtures are intended for bases from a certain brand concrete. Self-leveling solutions with antistatic properties are manufactured. Paul covered floors do not attract dust.

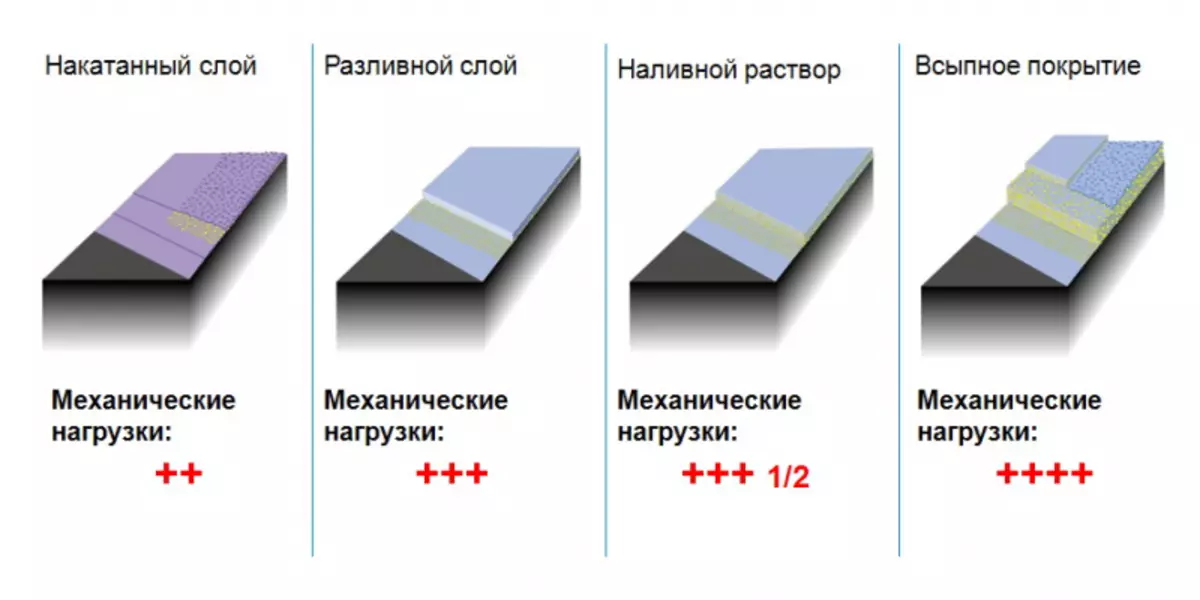

The choice of polymer mixture with certain properties depends on the following factors:

- The degree of preparedness of the foundation.

- Estimated operational loads.

- Temperature conditions of operation.

- Specific features of the room.

Technical characteristics of floors.

Leveling mixes for

The finish fill of the floor can be applied to various, pre-prepared grounds. On the package, be sure to read the manufacturer's recommendations regarding the compatibility of the bulk sex with the base surface.

Article on the topic: We consider all the properties of GF 021 and other similar mixtures

To accurately complied with the technology of the floor device, a special tool will be required for:

- Grinding machine, vacuum cleaner;

- Capacity for breeding the mixture;

- low-unique drill with a nozzle as a mixer;

- Raochel for moving the layer plugged, wide spatula;

- needle roller, roller and brush for priming;

- Spikes paint.

Preparation of concrete base for filling the mixture

Preparation of the base for the filling unit.

The differences of the non-prepared concrete surface should not exceed 4 mm when controlling a 2-meter rail. Especially significant this moment at a thin layer of finishing coating. On a fairly even concrete basis, the surface grinding is performed for its preparation, the removal of the sludge and dust, seelings of cracks and chips. To enhance adhesion, the black floor is primed.

With significant changes in the level of the draft floor, a preliminary alignment of concrete screed or leveling, similar to the composition with a bulk finish floor. Plastic levels differ from self-leveling mixtures by a larger fraction of components and less fluidity. To fill them, you will need to install beacons. You can use the profiles for drywall. To level the base base in terms of level, they are installed on a cement solution.

The concrete screed must be carefully sucked and dusty.

High-quality fill can be performed only with the full filling of the reasons that subsequently will allow to avoid the appearance of bubbles in the structure of the bulk sex.

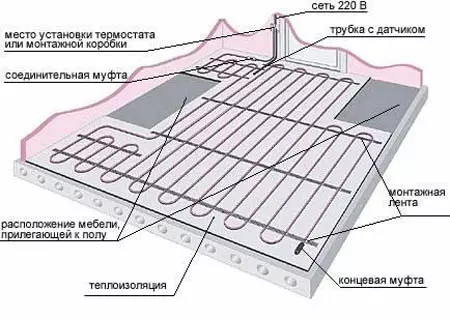

Floor circuit with electric heating.

Strengthened impregnations are applied to the surface, for example, "Aquastone" or "Epoxol".

It is extremely undesirable and content in the material of the base floor of moisture. In the process of applying a liquid composition, it is blocking in the base structure. To check how much the draft floor is succeeded, you can apply the composition in a small area and evaluate the quality of the coating after hardening.

The concrete base located on the ground should have waterproofing from below. The capillary penetration of moisture will result in the detachment of the polymer during further operation.

Article on the topic: The primer of deep penetration facade for various materials under glue, paint, putty

Black bases for bulk floors

Technical characteristics of leveling mixtures for floors.

Ceramic floor tiles can be filling if all tiles are firmly glued. Unstable elements are removed, the recesses are covered with putty, then the entire area is degreased by an organic solvent. Priming can be carried out by polyurethane composition of PS-soil. If the intercutric seams are insufficient enough, the primer is applied again after drying the first layer.

The fill of the filling floor on the wooden surface is possible, but conjugate with some difficulties in preparation. Wood is susceptible to temperature deformations, which may affect the structure of the bulk coating.

From the surface, it is necessary to remove the paint and close the slots between the boards using a mixture of small sawdust and PVA glue. You can apply acrylic wood putty. The surface is grinning and carefully removed dust. A reinforcing mesh is stacked to prevent the filling floor cracking before the fill. Along the walls should be punctured by damper tape.

Wooden floors can serve as a base for bulk sex, if they are sufficiently stable and the moisture content of the wood does not exceed 8%. Printing Prepared Tree surface does not require. If the wooden base does not inspire confidence, replace it with a concrete screed.

On the old bulk coating, the composition is applied with pre-grinding. It is necessary to specify the compatibility of the updated layer and the new mixture. When laying the system, the warm floor under the bulk coating the polymer levelover is flooded in layers. Pipes with pouring filled with water.

About the process of filling the bulk floors

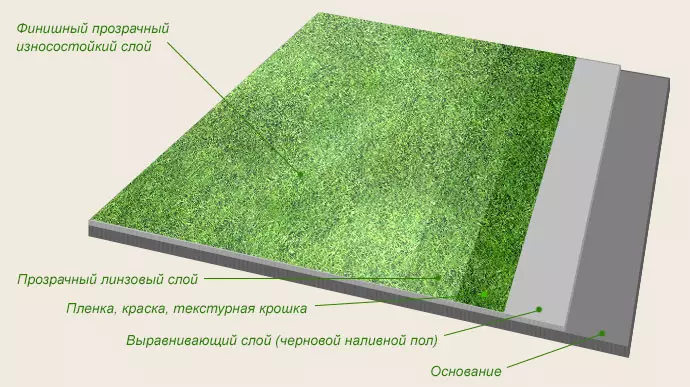

The diagram of the filling floor device with a three-dimensional effect.

The liquid components of the finishing coating for the liquid floor device are delivered by the manufacturer in the kit. The ratio of the components of the mixture is set when packaging. Carefully read the instructions on the package before mixing the components.

Pouring the polymer mixture is better to produce with an assistant. Premises with an area of 15-20 m2 must be pouring within an hour. One of the employees stirres the mixture, the second pours the mixture to the surface of the floor and smoothes with a rochel with the adjustable working part height. The process of filling the floor starts from the far from the input of the angle. Another portion is poured at a distance from the previous one, allowing them to flow. In places in the walls, the layer is leveled with a toothed spatula.

Article on the topic: Soundproofing of inter-storey wooden floors - the choice of material and method of device

After uniform spreading of the solution, the layer is rolled with a needle roller. The length of the needle tool should be slightly more of the thickness of the coating layer. Bubbles of air from the structure of the filling floor are removed by rumbles and its surface is aligned.

The layer thickness should not be less than 50 mm. For its control, special metal beacons are used (tripods), installed at an equal distance. For moving on the coating, paint is used - a device on long spikes, fastened to shoes.

Aeration can be performed within 30 minutes after spreading the layer. The layer is frozen depending on the type of polymer coating, air humidity in the room and the thickness of the layer after 1-2 day, but the complete hardening occurs only in 5-7 days.

In the period of setting the polymer mixture in the room there should be no drafts and direct rays of the Sun. Ventilation should not be intense. For a protective and decorative effect, the floor after final drying is covered with polyurethane varnish.

The filling technology of the bulk sex is not difficult, it is important only to understand its specifics. These knowledge will be useful not only for the device of the bulk sex with their own hands, but also when handing the manufacture of coating by the hired workers.