In any house requires a stepladder. This enlarged stool (or stand) with long legs allows you to get things that are too high. It will be useful when replacing the light bulb and greatly facilitate the removal or hanging of the curtains on the eaves. The design in the country area will become an indispensable assistant when harvesting or forming crowns on trees. The staircase of the stepladder will make it possible to take into account all the nuances and the requirements of the owner and the master.

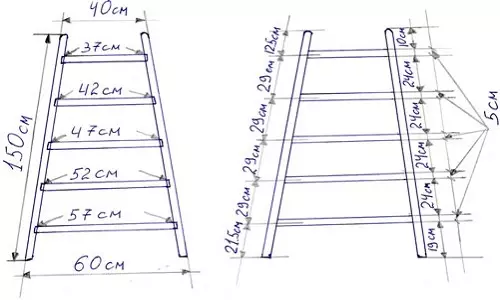

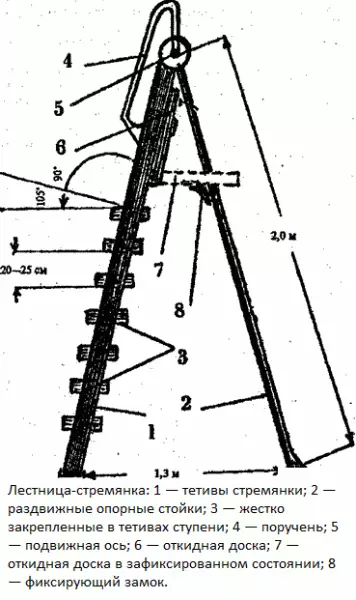

The drawing of the stairs for the manufacture of a stepladder.

Selection of models and materials

There are several varieties of such small ladies, among which it is quite possible to choose a suitable one. The most common stepladder, which is a stand with the legs screwed to it. These supports can be folded, while the place occupied is significantly reduced. The design of the ladder can be more complex. For example, it can be performed in the form of a stirrel stool. It develops and is converted to a chair that can be used for its intended purpose. Another example of an unusual device of a ladder can serve as a ladder, in which several tiers can take shape due to the presence of guide and special fixators.

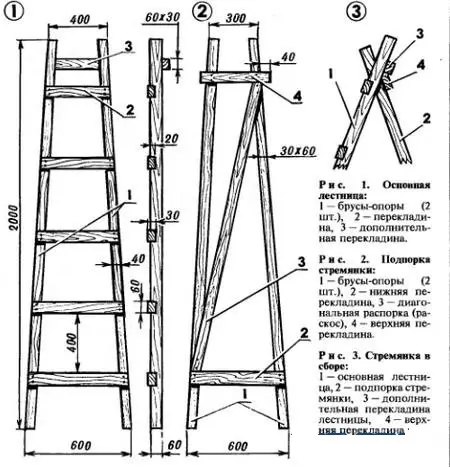

Drawing of stairs stirrer.

The stepladder can be made of metal in combination with a tree. But at the same time, if it is made entirely of wood, it is not at all inferior in the strength and reliability of metal analogues. It is the tree that is the material from which the stool is a stepping with their own hands will be the optimal option.

Wood, except for ease of treatment, has a number of advantages (environmental friendliness, natural beauty, the possibility of making from undergraded means), which allows it to choose it as the main material.

In order for the stool of a stepladder with their own hands is quite reliable and sustainable, some proportions must be observed. For example, the seat (or reference site) should be a size of 30x50 cm, the distance between the supporting leg and the adjoining - 60 cm. The number of steps will be determined independently and depends on the step of their location. For such dimensions, there are enough 2-3, which are located at a distance of 20-30 cm from each other.

Article on the topic: Homemade constipation for garage gate (drawing, photo)

What happens to work?

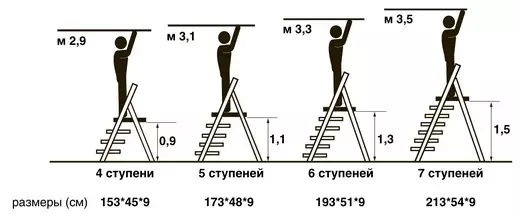

Scheme of the ratio of the height of the stepladder with the number of steps.

The staircase stratum begins with the fact that it is necessary to prepare all consumables and tools with which work will be performed:

- electrical or rechargeable drill with drills that are suitable for wood work;

- self-tapping screw;

- bolt, nut and washer;

- Electric jigsaw or saw with small teeth;

- roulette, pencil and square;

- sandpaper;

- Olife and varnish, brush for applying them;

- Wooden bars with a cross section in 40x70 mm for racks;

- Rake cross section in 20x70 cm for base.

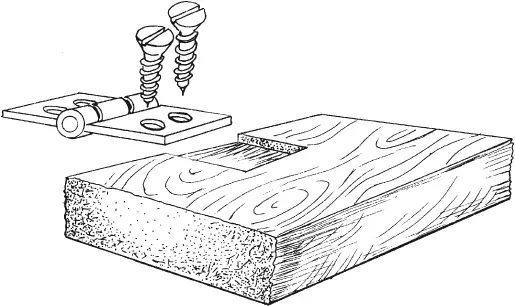

Mounting scheme loops for stepladder.

The design of the staircase provides for a sequential manufacturer and assembly of parts:

- seat or reference site;

- Racks for support;

- staircase with steps;

- Reiki, which grouped all the details together.

Start with the fact that the dieted segments are cut off with the help of jigsaw. They should be without bitch. After the spil is made, it is necessary to process the surface with sandpaper or grinding machine. This will make the surface smooth, but will save the color and texture of wood. Separate 7 parts: 5 - for seating and 2 - for jumpers.

In order to make a comfortable seat, as well as a convenient platform when climbing height, it is enough to bind 5 times with each other. They will serve as the basis that the transverse crossbar must be born. For this, 5 speeches are placed at the same distance perpendicularly. Cropped with each other details can be 2 ways:

- With the help of self-tapping screws, the caps that must be burst;

- After performing the grooves, equal to the width of the crossbar on the main rails, and gluing the elements of the seating.

If gluing is chosen as an attachment, then after the end of the work it is necessary to give glue to frost, and the seat is to gain rigidity and reliability.

Article on the topic: Features and properties of fliesline wallpaper

Parts of the support structure

The main type and size of a small lap.

Supporting elements are cut off from the bar. He just like the rails should be of good quality, without chipping, cracks and other damage that can disrupt the reliability of the ladder in the future. If you still avoid the use of the bitch part, it may not be possible, then maybe there is a need to revise the design of the ladder, which will allow you to more rationally use the source material. The final distance between the supporting details should be such that the previously made seat can accurately fix it.

The reference part is a combination of 5 segments of bars, 2 of which are the main, and 3 are connected. Two of the fastening parts are perpendicular to the main one. They form a rectangle, and one is attached diagonally. Such a compound provides the necessary stiffness of the structure.

They can be connected using a specially performed joint of the spike grooves or screws and a screwdriver. If the mount without the use of metal elements is used, then after performing the groove and spike, it is better to skim these parts before assembly. After that, it is desirable to arrange the entire assembled design between 2 boards, which will tightly hold it until the glue is completely frozen.

Installation of stairs: Recommendations

The elements of the staircase can be made from the bar, and its steps from the rail.

Device staircase ladder.

But it should be remembered that the guide stairs must be unlocked with the fact that in the future they will be at an angle to the horizontal surface. At the same time, the steps have strictly perpendicularly.

The angle on which the staircase will be fixed can be determined by selection. To do this, it is necessary to collect without fixing all the elements of the stepladder so that the distance between the support part of the stepladder and the staircase is about 60 cm. It is necessary that the seat (or top pad) is strictly vertically. After determining the corner, he was spiling.

Article on the topic: Installation of MDF panels with their own hands (photo)

On the side parts of the stairs make feeders, which are equal in the thickness of the height of the steps. The number of holes is equal to the number of steps. After that, the prepared elements are placed in the propuls and fixed with glue. Fastening can be made on the self-tapping screw. Additionally, under the steps you can fasten the planks that expand the platform for the support of the step.

The staircase, supporting construction and seats are connected to each other. So that there are no problems when folding, the upper parts curve. Then they will not engage at each other. The mount is performed on the bolts with nut and washer. This fastener allows you to fold the stirrer for storage.

The finished product is covered with primer and several layers of varnish. Moreover, on such details, like steps and seats, it is better to make their number of large. This is due to the fact that these items are most susceptible to wear.