When construction, repair and maintenance of a private house or cottage has some work to do at height. With the help of anxal staircase, not everything can be done, and not very comfortable. Much more convenient to use scaffolding.

From the palm ladder is not so comfortable to work

Homemade scaffolding of wood

Metal scaffolding, of course, reliable and durable, but most often they are made of wood. Everything can work with wood, and everything you need - saw, nails / self-tapping screws, hammer / screwdriver / screwdriver. A set of tools is a simple, which is found from any owner, and if there is no something that is not required to purchase a lot of money. Metal in this regard is more difficult. It requires at least some kind of reference skill, the presence of a welding machine and at least some idea how to correct the seams. That is why scaffolding with their own hands in most cases are made of wood.What to do

Everyone is clear that the scaffolding or scaffolding is needed for a short time. But it is necessary to use the construction wood of good quality for their manufacture, with a minimum of bitch. Some masters advise forest forests exclusively from ate. Unlike pine, the swirls are located single and the strength of the board almost does not affect.

But spruce boards rarely have in stock, but pine is usually enough. From pine boards, construction forests can also be done, but each of them must be checked (in any case, which goes on the racks and flooring). For this, there are two columns (three or four bricks one on another, a couple of building blocks, two boulders, etc.). When checking the three-meter boards, the distance between them - 2.2-2.5 m. On the columns are put on the board, it is jumping up on the middle a couple of times. If there are weak points, the board will break or crawl. Withstand - you can use.

Board for forests used good, without bitch

About the thickness of the board should be said specifically, tied to the construction of scaffolding, distances between the racks and the planned load. The only thing that can be said is that the racks and the flooring are most often used the board with a thickness of 40 mm or 50 mm, for shusin - 25-30 mm. Such a board can be used in the detailed construction work, if it is possible to disassemble it without damaging it.

Nails or selflessness

The dispute about that, nails or self-tapping screws is always going, but in this case it is aggravated by the fact that the work is carried out at the height, and increased reliability from the design. From this point of view, it is better nails. They are made of soft metal and in the presence of a load, they bend, but do not break. Self-tapping screws are made of hardened steel, and it is fragile and in the presence of shock or variable loads break. For scaffolding it is critical - there were cases when they were collapsed. But this is a question of "black" self-drawing. If still anodized - yellowish green - they are not so fragile and can well withstand all loads. If you are seriously worried about the reliability of forests, it is better to use nails. They do not like them due to the fact that disassemble the connection quickly and without loss will not work - most often the wood is damaged.

Even anodized selflessness breaks

With independent manufacture of scaffolding, you can do this: initially collect all on the anodized screws. If the design is convenient and correct, to progress, driven by two or three nails into each connection. In order for the disassembly to damage the wood, under the nails you can put trimming of thin boards, and whole boards, but small thickness can be used on the extended span. When disassembly from you can split, and sticking nails are easy to remove.

Article on the topic: Hosterans note: how to hang curtains on a curtain ribbon

Constructions and their features

For different types of work, various construction materials and scaffolding are used. For work with lightweight materials, too large carrier ability is not needed. In such cases, the pre-abilities or the abilities are made.

Convertible envelope. Despite the seeming unreliability, it is convenient to work with them

For works on the front or with an outer finish of a low single-storey building, building goats use, on whose crossbars are laid down.

If you can do nothing on the walls, building goats are suitable with laid on the crossbar

For masonry walls of bricks, any building blocks, for trimming facade with brick or stone - for all these works, already full-fledged scaffolding.

Scaffolding from wood to increase stiffness reinforce and disconse

As a rule, all these structures are not attached to the walls of the building, but are fixed by the stops that support the racks. Next, let's talk about each of these structures.

Attachments

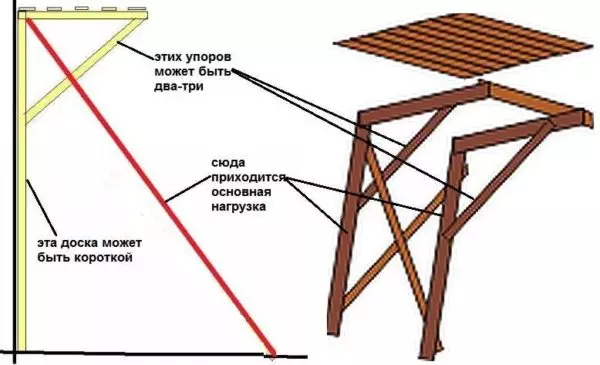

Called so because of what is usually not attached to the wall, but simply lean. They are held at the expense of the stop. The larger the scaffolding of the scaffolding, the stronger they cost. There are two designs, both of them are made in the form of the letter "g", only deployed in different directions.

Drawings of dotted building scaffolds (two types)

In the picture on the right, a simple and reliable design of the scope. The only drawback is not regulated in height. Convenient, if necessary, for example, to strip out of the roof, mounted or clean the drain, all those work that have a small variation of the height. Some even adapt similar scaffolding for the construction of a house of logs (timber). Through the fins of the stops conveniently roll or raise logs.

They are reliable - withstand 11 meter logs and three people

Construction Scaffolding - Simple Design

In the picture on the left of the monastery, the envelope or Armenian scaffolding. The design is simple and reliable, although it does not seem so. But it has been tested for many thousands of houses under construction. Attractive in that it requires a minimum of building materials, to collect / disassemble / move them in minutes. The main thing is to make triangles, and the installation at a given time takes away a bit: lift the triangle, resting the inclined beam, which is fixed in the ground.

Triangular stops for Armenian forests

The manufacture of triangles is a bottle with a thickness of 40-50 mm, 100-150 mm wide. The vertical part may be long - it is convenient to raise the scaffolding for a given height. The upper crossbind is made by dina 80-100 cm, the floorboards are stacked on it. By the way, they are also 50 mm thick, and the width is the more, the better, ideally 150 mm.

In the manufacture of corners, the junction must be positioned so that the horizontal board is from above. To increase the reliability of this node, you can use metal lining in the form of a corner. But if the corner will be fixed with the help of three windows, nailed on both sides, there is no need.

The triangles of Armenian scaffolds each meter is established.

These triangles are installed approximately through each meter. If the facade allows them, they are nourished if not - only gravity is cost. The main load in this design accounts for a stubborn board - the one that puts at an angle and one end rests on the ground, another - in the top of the triangle. These stops are made from the bar, the boards with a thickness of at least 50 mm, the pipes of the solid diameter (at least 76 mm) or section (for a profiled pipe at least 50 * 40 mm). When installing the stop, it is put exactly into the angle, clogged into the ground, additionally fix, driven wedges.

Stops put exactly in the angle

Drives are driven into the ground, additionally recorded wedges

Article on the topic: How to collect Karnis Magellan: measurements and installation

To eliminate the possibilities of the side shift, the established stops are fixed by several bodies connecting them into a rigid design. Here for these types you can use the unedged board, if it is, but sufficient thickness and widths.

Installed stops are knocked down by

If there is a need to be resistant to grow (if they need more than 6 meters long), for such a board there are additional emphasis. It rests on about the middle of the main, removing part of the load.

How to make Armenian scaffolding on the outer corner

Now a little about the flooring of these filter scaffolding. It is made from a wide board with a thickness of 40-50 mm. In this case, they should be fixed to the triangles at least on the self-tapping screw. This design does not provide for the presence of a railing, and the slightest movements under your feet will cause increased discomfort. Therefore, fixation is extremely desirable.

Wooden scaffolding: drawings and photos

The options described above are good if the work does not assume the presence of heavy materials. It is also not always possible to drink the forest on the wall - any ventfassad or a multi-layered wall - and you can not have a similar design. In this case, there are full-fledged forests. Their design is also not complicated, but a decent amount of lumber is required.

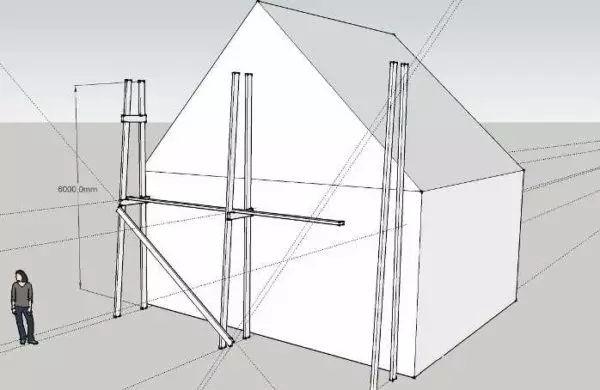

Scheme of scaffolding from boards

For their device, the boards of a significant thickness are used - 40-50 mm. First collected racks. These are two vertical timber or thick boards bonded by crossings. The size of the crossbar is 80-100 cm. They must be done on the basis of the fact that the minimum more or less convenient width of the flooring is 60 cm. But it will be much more confident that you will feel if you have at least 80 cm. To give the design of greater lateral stability Racks can be made with tights up.

So that the forests are not covered with the wall of the house, the crossbars can be made with the release of 20-30 cm. They will not give the designs to fall towards the house

Racks put at a distance of 1.5-2.5 meters. The span from the thickness of the boards, which will use for the flooring - it is necessary that they do not begged. The racks installed at the required distance are bonded by shakes. They will not give the designs to work out. The larger the crossing and streamin, the more reliable the scaffolding is obtained.

So that the scaffolding do not fall, they are supported by boards / bar, one end of which is nailed to the racks (nails), the second - Zapyan to the Earth

Transverse beams do not make it possible to work out, but still the possibility that loose forests can fall forward. So that it does not happen, the beams are supported by bodies. If the height of the forests is 2.5-3 meters, this can not be done, but if you need to carry out work at the level of the second or third floor, such fixation is necessary.

Wooden scaffolding do it yourself in a couple of days

If the work will be carried out at high altitude, it is advisable to make a railing. They can be made of not very thick blackboard, but bumps should not be, like cracks. The handrails will help you feel at the top more confident to those who are afraid of height.

The construction of scaffolding is modular, easily increasing to the necessary height and shape

To the level of overlapping the second floor there is enough standard hand - 6 meters

Inconvenient such forests in that they have to fully disassemble, if there is a need to move to another wall

You can collect small scaffolding from old, but strong boards. Sometimes for the sidelines and stops use poles or pipes - what is in the farm

Building goats

There is still a way to make light mobile scaffolding - to build the same building goats, stinging with a certain step of the crossbar, which will be simultaneously both the staircase, and the layer for the flooring board.

On the crossbars are laid down the flooring boards

Such a variant of the scaffolding is good, for example, when climbing at home siding. The sheathing goes from the bottom, the height has to change all the time, leaving or fixed to the wall there is no possibility. Therefore, this option for such a case is the best.

Article on the topic: Wallpapers

Building goats - options

Sometimes one rack on one side make vertical, without inclination. It allows you to install them closer to the wall, the flooring is then located closer to the wall. In some cases it is convenient - for example, with pantry, painting, preventive processing.

Types and assemblies of metal metal

When building a house of stone, building blocks, metallic forests are more suitable. They are able to endure any load. They are less popular for the reason that in many regions wood is still the cheapest view of building materials. The second moment, which is often decisive, is the breaking of wooden scaffolding, boards can be used to be used in the future construction. And parts of the metal must be dust in the barn.

But the metal construction forests have pluses. In disassembled state, they do not occupy a lot of space. The owners of wooden houses still occur periodically to use them: the log house requires care, so once every two or three years needed. Practical in this case are metal, not wooden. They are easier to assemble, durable and stronger.

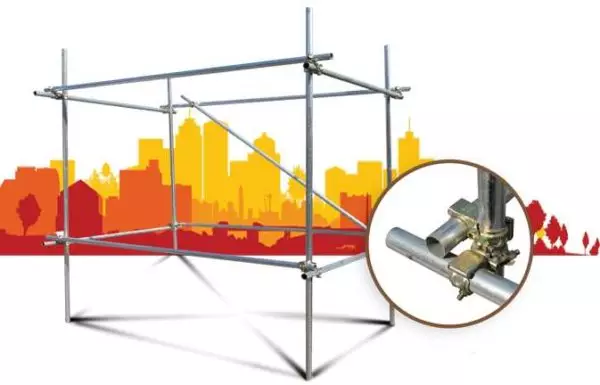

All metal scaffolding has the same form - vertical racks connected by crossbars and hide. Only the method of fastening parts between themselves is different:

- Pitry forests. Called so due to the fact that crossbars with racks are connected using pins. The cuts of the pipe or discs with perforation are welded on the racks, and on the crossbars - reinforced pins. As soon as such a system is very simple, withstands heavy loads. Very simply implemented pin construction forests for buildings of simple shape, bypassing erkers and protrusions - much more difficult.

Principle of connecting pin forests

- Clamps. For the racks and crossbars, the pipes of the circular cross section are used, which are bonded with each other with the help of a special design clamp. The system is very mobile and movable, you can easily bypass any curvilinear facades. Minus - limited lifting capacity and height (according to GOST - no higher than 40 meters).

Clamps - quick installation / disassembly

- Frame. Frames of the same size are welded from a round or rectangular pipe. They are connected between the transverse pipes and bodies. They have a modular structure, easily increasing both in height and in length. They have a certain step in length - 1.5 / 2 / 2.5 / 3 meters, in height, one section is usually 2 meters, the standard depth is 1 m. In some frames, wheels are provided for easier movement over a flat surface. The connection of the flag-type elements - the pins with a slot in the frame are welded into which the checkbox is inserted. Openers are made in crossbars and hills. Elements are put on the pin, fixed using the checkbox. The section is increasing using connecting pipes of smaller diameter, welded to frame racks on one side. With this method, ideally selected pipe sizes are important so that there is no backlash.

Frame forests - the principle of fastening of the cross and Ukusin

- Wedge. With the overall similarity of the design differ in the compound form. On the jokes with a certain step (usually 2 meters) welded discs with perforation. On the jumpers from both ends, special locks like "Wolf Pave" are welded. The locks are fixed on the disk using the wedge of a special form. Such forests are connected and separated quickly, have high mobility, can be used on the facades of complex forms.

Wedge forests racks and crossbreaks connect with wedges and special lock locks

With independent manufacture of metal scaffolding most often make pins. They are being implemented the easiest way, however, they are only good on rectangular facades, to bypass more complex forms, you have to do additional tubes.