Features of the plumbing product

Today, the plumbing market is filled with a variety of products. Some of the demanded goods are sinks of stainless steel. With their acquisition, each hostess gets a kitchen accessory with increased practicality, hygienicness and ease of use.

Without a sink, no house is required. When the washing is selected, you can proceed to its installation, which is not so difficult to perform with your own hands.

In addition, stainless steel washers are characterized by:

- attractive appearance;

- corrosion resistant and mechanical damage;

- unique harmony with a kitchen decorated in any style;

- acceptable cost;

- Simplicity of installation and care.

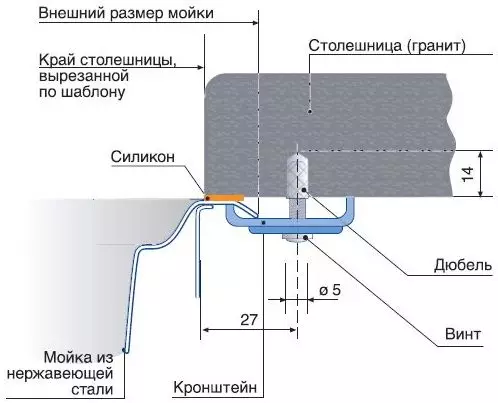

Sink installation scheme: 1 - gasket; 2 - clamp.

High-quality washing fasteners are impossible without using such materials and tools as:

- electric jigsaw;

- degreasing liquid;

- file;

- sandpaper;

- roulette;

- level;

- pliers;

- rags;

- foam sponge;

- brush;

- sealant;

- drill;

- screwdriver;

- screwdriver;

- pencil;

- self-tapping screws with a press washer;

- dowels;

- bolts;

- welding machine;

- formwork boards;

- wire;

- concrete solution with a container for kneading;

- Master OK;

- bucket;

- Metal bars;

- a set of keys.

Installation of a separate plumbing product

Sink fasteners can be carried out in several ways.

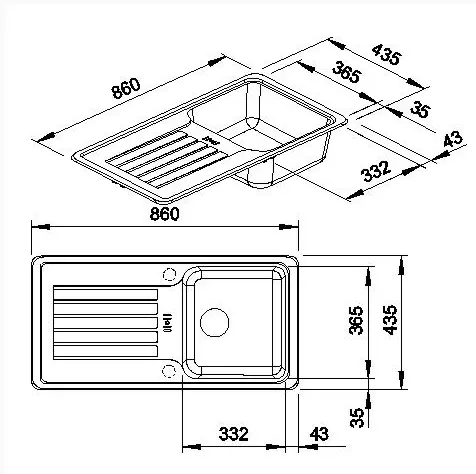

Dimensions of kitchen sink.

This process depends on:

- type of surface where the washing is embedded;

- Its shapes and size.

For a separate washing without a platform, wooden bases (or similar to them) are commonly used. For such bases, mechanical fasteners are selected. The base is placed on the landing form of the sink. A hole is cut out: it should perfectly repeat the sink circuit. If necessary, you need to handle the edge with a file or emery paper.

Installation washing is carried out at the prepared place. It is checked by the density of the adjustment of the stainless steel to the hole made. If there are shortcomings, the hole is refined.

Article on the topic: How to make a circular table for an electric bike with your own hands?

Removes the litter remaining after the jigsaw. The surface is clean, rubs and processed by degreasing fluid. No need to use household chemicals: Fairy, Domaset, etc. For this purpose, only verified means are necessary: gasoline, acetone or alcohol. With the help of a foam sponge, the liquid is applied to the outer and the inner edge of the base. It must completely evaporate.

The sealant is applied to the sealer seal. Its quantity is difficult to calculate. The main thing is that with a complete shrinkage of the shell in its place, the sealant covered the entire circle or perimeter of the inserted design. The surplus of the sealing composition is removed a slightly moistened rag.

For a larger effect, you can use moisture-resistant universal glue, which is mixed with sealant. The mounting brackets located at the bottom of the washing are straightening and with the help of self-tapping screws are attached to the base. Then the mixer and the sewage plum elements are mounted.

Construction fastening with high hollow borders

Installing a dual sink.Installation of miles that have high hollow borders, is carried out in the base with a thickness of at least 75 mm. The sink is attached to the intended installation site and will be burned with a pencil. By its contour, a fitting seat is cut down. The jigsik is reconfigured into a non-separated cutting mode and the groove is selected under the outer side of the boral.

The degreasing procedure is carried out using a foam rubber or brush. The degreasing solution is applied to the entire area of sinking and base. The design should dry to the complete disappearance of the sharp smell of the fluid. Stainless steel is put in place.

The outer rim is neatly and without excessive rush connects with a groove prepared for it. The junction is processed by a sealant. Excess material is removed with a rag or sponge. Installation of the mixer and the connection of washing to water supply and drainage systems is carried out.

Creation of frame and built-in in the kitchen design

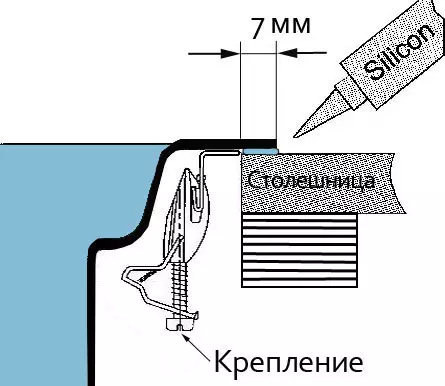

Sink installation circuit.

For the first option, a metal bar is required with a diameter of at least 16 mm. It is bent according to the exterior form of the stainless steel. Fasteners of the finished frame are carried out using conventional welding or bolted joint. The frame is evoked by the level and fixes. The car wash is superimposed on it and its final installation occurs.

Article on the topic: Installing the closer on the door with your own hands: Schemes (video instructions)

Elements are used for attachment in the form of precipitated handles on both sides. The only requirement of using such a construction is thorough and advanced preparation of the base (priming and staining).

When installing the design embedded in the kitchen, glue and sealant are used. The tabletop is drinking the seat hole, and the edges are cleaned. If there are tabletops made of stone, cut is processed with a file. So it turns out a rough surface.

A layer of glue is applied to the inside of the cutout. Motion is made. Some time we give the glue to grab, after which the sealant is applied to the place of contact of the sink with a worktop. The elements of utility networks are attached.

Stubborn installation design

Scheme fastening "mortise" washing.

When the car wash will be used without any lockers and bedside tables, it is based on the score indicator. To do this, it is necessary to make 4 points of support, which should be at the corners of the mounted design.

The washing is attached to the wall and there is a horizontal level of its location and the place of the mounting holes. Holes under the dowel 5 mm are drilled and the mounting elements are inserted. Holding the sink, screws twist up to the stop.

There is another way of fastening stainless steel products. It is used when a design of two symmetrical parts is created. Planck is attached:

- To washing on a self-tapping screw with a press washer;

- To the wall on the dowel.

This type of installation makes sense when observing the slope between the washing line and the fastening plate in the amount of at least 45 degrees. Moreover, the mounting plate can be at the bottom. The magnitude of the slopes remains unchanged, but the material used must have a reserve of the fortress.

Installation of kitchen accessories in a concrete "shirt"

Perhaps this method of installation is the most aesthetic. Although the most time-consuming process. First, formwork is manufactured with boards. It must mostly repeat the contours of the inserted sink. In some cases, overall dimensions can be underestimated by natural stone processing. In the middle part of the formwork is inserted by a sewer tube under the drainage. It is located below the level of the lowest sink.

Article on the topic: Plywood laser cutting features

The pouring of the concrete solution occurs in two stages. The first is the overall fill of the lower and middle part of the future pedestal. Through the corners are welded or glued with thick pieces of wire. They provide a reliable installation of stainless steel on the already grabbed solution.

The second stage provides for the complete coverage of the walls of the washing with a pliable solution. It is impossible to make a concrete on the inner walls. If this happened, it is necessary to immediately remove the surplus with a damp cloth or a piece of foam rubber.

Stainless steel is a very thin product. Therefore, it is mandatory to eliminate mechanical impact on it. In order to do not blur in the process, it is necessary to leave it with old newspapers with painting scotch.