The development of modern technologies allows the use of polymeric substances to create any finish materials and interior elements. Especially good such a polymer as polyurethane. It is easy and durable, due to which it became very common in a variety of finishing and construction work.

Polyurethane products are completely safe for ecology, and for human health, which allows you to freely use them in any premises, including residential. One of the most popular types of products produced from polyurethane is a base plinth.

Polyurethane plinth possess many advantages over traditional types of plastic, wooden and polystyrene foam.

Advantages of polyurethane

- Long service life.

According to the manufacturers, polyurethane plinths are capable of serving for at least three decades, without losing the aesthetics of the appearance, nor performance characteristics.

Polyurethane plinth does not absorb the smells of ambient air, resistant to humidity, which allows it to apply it even in bathrooms without additional sealing, and is also not affected by microorganisms - fungus and bacteria - which often ruins wooden models.

- Resistance to critical temperature values.

Polyurethane plinth can be glued in rooms without heating, where it is not deformed even in frost. Also, impeccably plinth will serve in places subjected to high temperature - for example, on the floor under the radiator.

- Simplicity and convenience of installation.

Polyurethane plinths have high flexibility and elasticity indicators, which makes it easy to glue them to the floor at uneven walls, ride columns, protrusions and niches in the walls.

The floor plinth of the polymer will successfully hide all flaws at the joints of the decorative floor covering with the walls. It is quite problematic to damage the material during work.

- Easy processing.

Article on the topic: Well-water well

Works on the installation of parts from polyurethane do not require the use of a special tool and high costs for materials. Cut the polyurethane stripes on the segments of the required sizes can be a simple knife.

The fastener is very simple - you can glue outdoor plinth with any adhesive composition, and it will safely restarts with the surface. Finishing can be made using any type of paint - acrylic, water-level paint, sprayers, etc.

- Easy to care.

Thanks to the structure of polyurethane, the rails from this material do not absorb dirt and do not hold the dust, which allows them to be purified by a simple damp cloth. If the floor washing is carried out using household chemicals or disinfectants, the preservation of edging floors can not be worried - polyurethane is absolutely resistant to chemical compounds of any kind.

- Diverse aesthetically attractive design.

Manufacturers offer a wide selection of colors, shapes and textures of polyurethane plinths. There is an opportunity to choose an option that fits in the interior of any style, even the most extraordinary.

- Functionality.

Many models play the role not only to decorate and protect the floor joints with walls. They are arranged special channels, allowing to hide electrical cables inside the plinths.

Features of outdoor plinths

Outdoor polyurethane plinth is used to perform three functions: underline the indoor contour, hiding the lack of flooring in the places of its joint with the wall and errors made during its installation, as well as the reliable fixation of the edges of the flooring of the floor, especially the floating parquet and laminate.

Polyurethane plinth fully performs all these functions, having an incomparable aesthetic appeal. In terms of its practicality, polyurethane surpasses wooden, metal and plastic options, much less demanding of ways and care of care. In addition, the price of polyurethane is significantly lower than more traditional materials.

Article on the topic: How to apply in the interior bronze wallpaper

Polyurethane products are presented in today's finishing materials market in two types: flexible and solid. The solid variant is reliable and durable and perfect for finishing direct sections of the perimeter of the room.

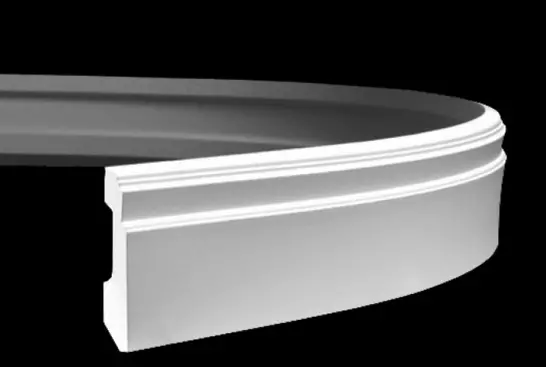

The second same species is very convenient if the premises are not a standard box with four walls, but has any architectural grace - columns, bends of walls, the podiums of the curved shape, niches in the walls. All of these non-standard design elements require the use of plastic flexible polyurethane plinth.

Polyurethane plasticity allows you to glue outdoor plinth from this material on the surface with almost any degree of curvature. However, it will be better to press it to the floor on uneven areas before drying the glue to ensure the best grip and impeccable appearance. Plinth is recommended after painting.

For coloring, coloring substances are suitable on any basis, the main thing - the paint should have a water resistance so that these interior elements do not lose freshness of the appearance too quickly. Moreover, nothing interferes from time to time to paint polyurethane planks.

Installation technique

Plinth glue to the floor is needed in several stages:

- Choosing a suitable model and the calculation of the required amount of material.

Typically supplied material with strips of two meters long. It is easy to calculate the desired number - it is enough to divide the perimeter of the floor for two, to deduct about ten centimeters on each corner and add joints in architectural elements - columns, niche and everything else.

- Preparation of walls and floor surfaces.

Cleaning the plinth can only after the finish finish is fully completed. Surfaces should be carefully cleaned, dry and take care of their evenness. Align the walls and the floor can be cemented on decorative material, all the same plinth will hide it all.

- Marking.

Plinths are applied to the sections of the future installation with a dense pressed to the surface of the floor and walls. It is necessary to schedule the joints of the joints and installing the fool, to measure and outline the circumcision on the workpiece.

- Slicing.

Article on the topic: Flooring knot for a warm floor with your own hands

Despite its strength, polyurethane plinth is easily cutting with a simple stationery knife, so it is not necessary to cut with a jig or saw, as in the case of wooden or metal plinths. In addition, there will be no completely no construction trash.

However, to ensure maximum levels of sections, the angles can be cut off with a joinery stouch. Of course, the joints of the walls are rarely perfectly even, so such accuracy may not need - in this case, the corners can be customized directly before gluing. After cutting, it is necessary to try again all the details to make sure that the cut is regular.

- Gluing.

This process should be started from any corner of the room. There are special grooves on the products, in which the glue should be applied. After that, polyurethane rails are tightly pressed against the wall and recorded with scotch until the glue dryness. On this process goes about a day.