You can increase the comfort of living in the cold season with floor heating. One of the options is an electric warm floor. It is mounted faster and easier than water, you can cope with your own hands without the involvement of specialists. Well, independently laying the electric floor under the tile, linoleum and laminate and will be discussed.

Electric floor heating device

If we talk generally, the electric heated floor consists of the following parts:

- heating element;

- floor temperature sensor;

- Temperature controller (thermostat).

It should be known that the heating element will work without a sensor and thermostat, but the work will be ineffective and short. Ineffective, because you will have to turn it on / off manually, and this leads to the overflow of electricity. And a brief, because with manual control, overheating often occurs, which negatively affects the lines of the heating element.

Electric heating floor components

Types of heating elements

In the market you can offer several different heaters:

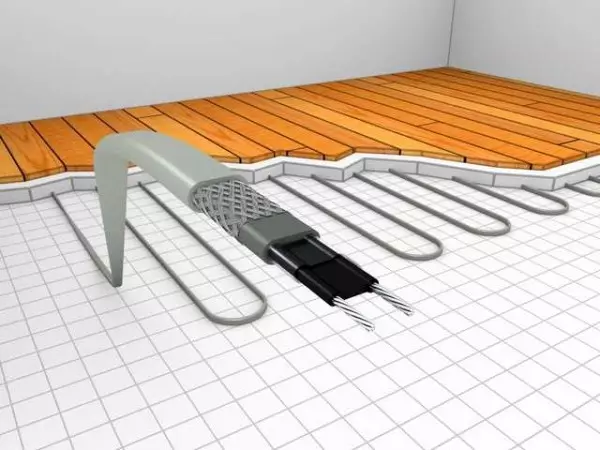

- Heating resistive cables. They have the lowest price, are single-core and bile, due to which the diagram of their connection changes. Their main disadvantage is the possibility of local overheating and fail (on a working resistive cable warm floor should not be installed for a long one). Therefore, when installing cables, do not lay down at seats, where furniture and household appliances will be. Another minus is a long laying process when installing.

Resistive heating cables

- Heating self-regulating cable. It has a higher price, but can adjust its own temperature on a single section in automatic mode, which avoids local overheating and extends its service life.

Self-regulating heating cable

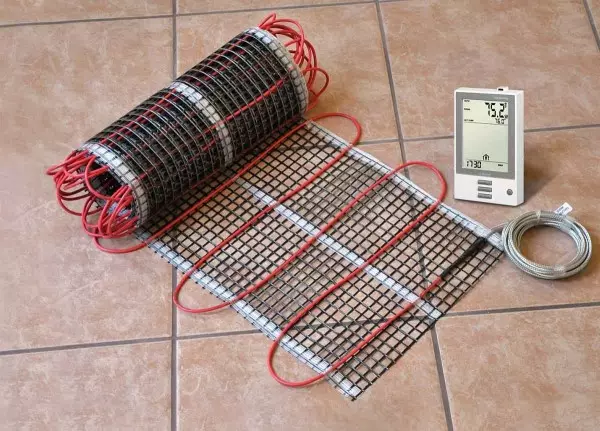

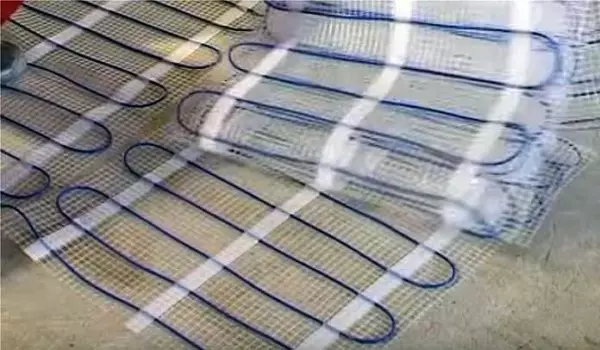

- Electric cable mats for a warm floor. These are the same cables, only enshrined in the form of a snake on the polymer grid. They can also be made from a resistive or self-regulating cable. Laying of such electric floor requires several times.

Electric cable mat

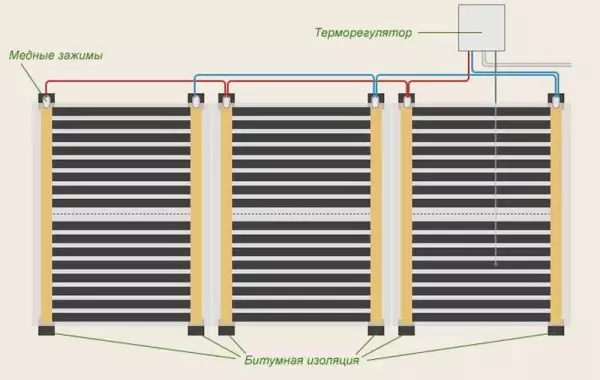

- Infrared carboxylic films. Between the two layers of the polymer, the carboxyment paste is posted, which, when passing through it, the electric current highlights heat in the infrared range. It is attractive to the release of infrared heat, with proper quality durable - if they are damaged by some part, only they are excluded from work, the others work. The plus is also quick installation, but the electrical connection is more complicated than at cables. Not very pleased with the price and this is the main drawback.

Carboral film - infrared floor heating

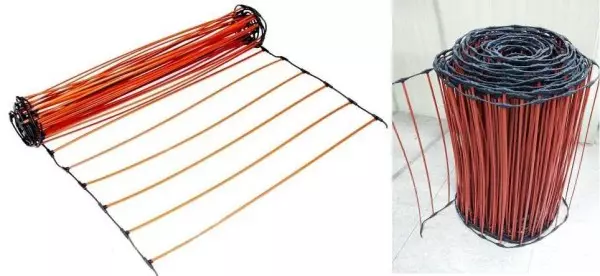

- Carbon infrared mats. These are rods with carbon inside, interconnected by electrical wires. The most expensive type of heating elements for electric heating floor, but, according to reviews, the most unreliable. They appeared not very long ago and the production technology was worn poorly, because the main problem is the failure due to the contact disturbance in the place of the junction of the carbon rod and the conductor.

Carbon mats for infrared floor heating

Which of these types of electric floor is better, it is impossible to say unambiguously. Everyone has pros and cons, installation features. Based on these, they choose the best option for a particular flooring - under the tile is better laying cables or mats, and under laminate or linoleum - film heater.

Types of thermostat

Temperature regulators for electric heating floor there are three types:- Mechanical. In appearance and the principle of work resemble the thermoregulator on the iron. There is a scale for which you exhibit the desired temperature. As soon as it drops at 1 ° C below the predetermined, heating turns on, becomes the degree above - turns off.

- Electro-mechanical. The functionality does not differ in anything, only eats a small liquid crystal screen and up / down buttons. The screen shows the current floor temperature, and the buttons it is adjusted to the desired side.

- Electronic programmable. The most expensive, but also the most functional. You can set the mode of operation (temperature) by the hour, and in some models and weeks of the week. For example, if everything went away in the morning, it is possible to set a low temperature - about 5-7 ° C, and in an hour and a half before arriving, program it up to standard. There are some models with the ability to control the Internet.

In some thermostat models for underfloor, there are built-in air temperature sensors and the ability to enable / disable heating in these indicators, and not depending on the floor temperature. So the choice is really there.

Electric warm floor under the tile - cable and cable mat

Cable mats are best suited for tile. In this case, such an electric warm floor should be made the easiest way, especially if it is already insulated and leveled. Insulation It is necessary that the heating costs are not too large, and even base - to ensure uniform heating and avoid the appearance of emptiness under the cable. If the cable is air, it will overheat and brave. Therefore, first make insulation and rough alignment of the floor, and then already putting a warming cable or mat.

It is harder to work with heating cables - they must be laid out for a long time, tie to the grid or fix in the locks. But otherwise - also a good option.

Electric warm floor under the tile

Cable Mata Mounting

We assume that the floor is insulated and aligned. There are too different situations and definitely say what should be the cake of the screed can only be in relation to each case.

When installing electrical heating of the floor of any type, mounting from the installation of the thermostat. It is located on the wall at a comfortable height, but not lower than 30 cm from the floor. It is installed in a standard mounting box (as a socket). Under the box in the wall drilled hole. To do this, use a drill with an appropriate nozzle - crown.

Drill hole for mounting box

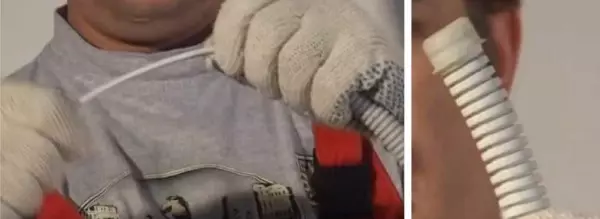

Two shoes are paved from the box down. In one, electrical cables will be laid from heating elements, to another - the sensor in the corrugation. The groove, intended for laying the floor temperature sensor, continues on the floor. From the wall, it should defend at least 50 cm.

Stroke under the temperature sensor should enter the floor at least 50 cm

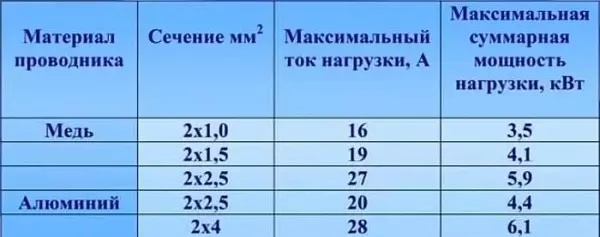

To ensure a warm floor with electricity to the thermostat, you must take 220 V. The wire section is chosen depending on the current consumed. Data is shown in the table.

Selecting the secting of wires to connect the power to the electric heating floor thermostat

After the shoes are made, you can start laying the electric warm floor with your own hands. To do this, the entire garbage is removed from the floor surface (carefully notice).

The surface of the floor must be absolutely clean

To improve the clutch of the screed and tile glue, it is ground.

Primer for better adhesion with glue

After drying the primer in the prepared groove, you can set the temperature sensor. He is lowered to the corrugated board (often comes with). The sensor itself is on the tip of the long wire. It is raised to the edge of the pipe, closed by a plug. The plug is necessary that glue or the solution spoil the sensor. After the tester check, did not damage the sensor during operation. If everything is fine, you can install it.

Sensor we bring to the corrugated

The corrugation is placed in the cooked stroke prepared in advance, we will bring the wire in the mounting box prepared for the thermostat.

We put the sensor in the groove

Wires we get into the mounting box of the thermostat.

We bring the cable from the sensor to the mounting box

The groove with the sensor is closed with tiled glue, follow the drops.

The groove is closed with tiled glue

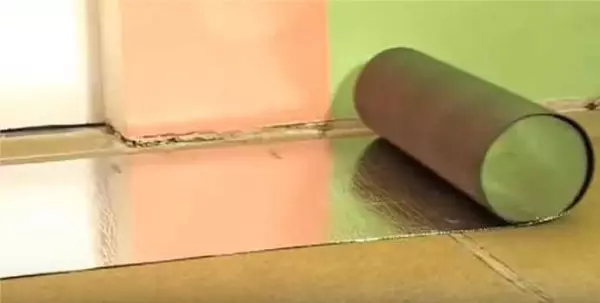

Next, to reduce heating costs, it is possible to unwell a thin layer of insulation with a laminated surface.

To minimize heat loss, it is possible to spread the layer of laminated thermal insulation

The heat insulation cannons are fitted close to each other, sinking the joints of the scotch.

Clear scotch joints

With this layer - metallized thermal insulation - not everything is so simple. If it is forked, the screed or tile is floating, as it will not have a connection with the base. Some manufacturers are recommended to provide communication to cut into the "windows" substrate, through which concrete and glue (or screed) will be associated with each other. Such a connection does not seem reliable.

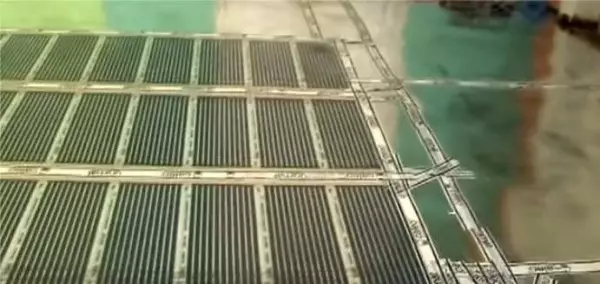

Next, place the zone that will be heated. We exclude places where furniture and large household appliances will stand. Also retreat from walls and other heating devices (risers, radiators, etc.) by 10 cm. The remaining zone should be covered with cable mats. They are dismissed on the required space. In a place where the mat must be deployed, cutting the grid, not hurt heating cable.

The grid is cut, the cable does not touch

Mat unfold (the cable serves as a link) and laid in the opposite direction (or at 90 ° if necessary).

Mat unfold

Please note that the panels of mats should not overlap each other, and heating cables should not touch. Between the two wires there should be a distance of at least 3 cm. Also laying out the electric warm floor, calculate so that the heap sensor is between two canvases.

Paul temperature sensor must be between cable turns.

Electrical cables from heating mats also start in the junction box. After installation, they need to call, checking the resistance. From the passport (there is in the instructions for each set) it should differ by no more than 15%.

Checking resistance

After that, you can connect the thermostat. Connection diagram is on the back wall (graphically designated what and where to connect).

Connect to the appropriate terminals

For better contact, the wire is better to raid (warm the soldering iron in rosifoli or soldering flux). Installation of conductors is simple: they are inserted into the socket, after which the pressure screw is tightened with a screwdriver.

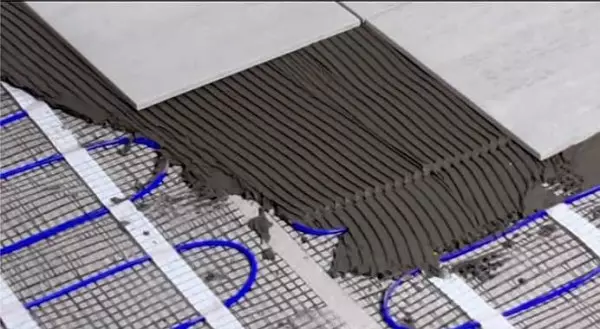

Next, briefly apply the voltage - about 1-2 minutes. Check whether mats warm and whether all sections became warmer. If yes, you can move further. We shut down the tile glue (special for a warm floor) and in small areas we apply to the cable mat. The thickness of the layer is 8-10 mm.

Apply glue in small areas

When applied, the glue is well pressed. There should be no emptiness or air bubbles. The lined layer pass the toothed spatula, forming grooves.

We form a groove

Now we put the tile.

On glue put the tile

It is necessary to work carefully, otherwise you can damage the cable. It is also necessary to ensure that the legs do not move mats from the place or do not break the cable. Electric cable warm floor is ready to use after complete drying (indicated on the package).

This method is not the best. It is easy to damage the heating elements during the work. In order to be guaranteed to avoid this, you can pour the cable mats with a thin layer of the level - the composition for coarse floor alignment. It has increased fluidity, thereby definitely not bubbles and voids. On the dried level, you can easily lay the tile without any problems.

Features of laying electric floor from heating cables

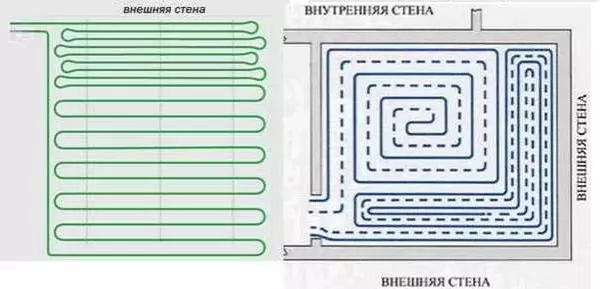

The main differences when laying electric warm flooring from the heating cable in the fact that the cable itself must be folded according to one of the schemes (snake or snail and their modifications) as well as the fact that this is necessarily poured with a screed thickness of at least 3 cm. Only after a set of concrete Design strength (after 28 days at a temperature of + 20 ° C) can be laid tile. So this version of the warm floor under the tile requires much more time, but it is suitable for any other kinds of flooring - under parquet, laminate, parquet board, linoleum and even carpet.

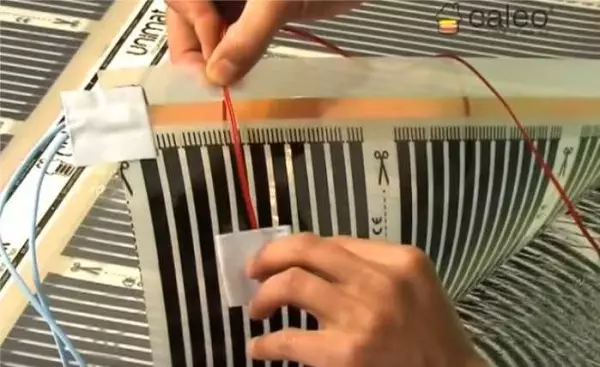

Now the process itself. Installation ribbons or metal mesh are fixed on the finished black screed over the insulation. As well as when laying mats, it is possible to lay a layer of laminated thermal insulation (with a shiny surface), but you can do without it.

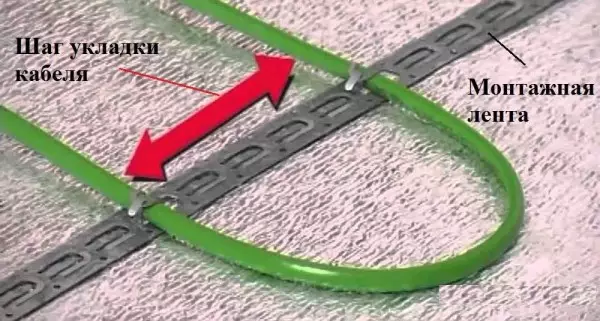

The mounting tape for the warm floor is unfolded along one of the walls in 50-100 cm increments. It is attached to the base on a dowel or self-tapping screw. The tape has tangible tongues that are fixed by the cable turns.

The principle of fixing the cable to the mounting ribbon

The second method of fastening is to the reinforcing grid cells. This option is good when the cake of the warm floor is made with insulation. The grid then still reinforces the screed and evenly redistributes the load on the insulation.

Laying the grid for mounting the heating cable

The grid should be made of wire at least 2 mm thick, cell size - 50 * 50 mm. This is the most convenient option when laying option - you can lay the cable with the desired step. The grid sections are binding to a wire or plastic clamps, in the same way they are fixed to the cells and the cable turns.

The cable will be pulled by plastic clamp

Why still choose a cable, not a cable mat under the tile? The cable can be laid with different step, given the features of the room. For example, put it more often along the outer walls, and the indoors take a step less often. With mats there is another output - use in cold zones fragments with greater power.

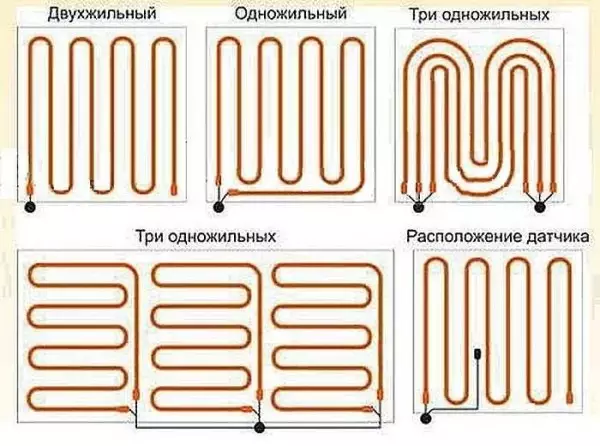

Standard cable layout diagrams

Layout patterns with enhanced heated cold zones

After laying the heating cable, the feed wires are reached in the thermostat mounting box, their resistance is also measured, then the thermostat itself is connected and the system is tested. If all the cable fragments are basked normally, you can pour the electric warm floor with a concrete solution. After complete drying, any floor covering can be stacked, including tiles.

Electric warm floor with their own hands under laminate and linoleum

For this type of coating, the use of film warm floor will be optimal. With an even base (a prerequisite for normal operation, if the floor of the curve is required, a preliminary leveling screed is required) the installation takes a little time, does not require screed or other wet works.Installation process in photo

Installation also begins with the markup of the heated area (not to launch under the furniture, equipment and low-hanging items) and the installation of the thermostat and the floor temperature sensor. Next, the heat-insulating foil substrate is rolled. Since there are no screeds, it can be used without any fears.

Roll over the heat-reflecting foil substrate

Material strips are rapped close to each other. Fixed on the floor can with the help of bilateral tape or top to shoot with brackets from the construction stapler.

Faster fixing the stapler

The stakes of the strips are sickling. Moreover, it is also desirable to take foil - to minimize heat loss.

We sink the joints of scotchball

Next, roll off the heating film. It cuts the lines applied on it into pieces of the desired length.

On the film there are special cuts of the cut

Film stripes are stacked close to each other or with a small gap, but not brand. Copper tire overlapping can not be allowed in any way.

Stripes roll alone near the other

One to another is recorded with a tape.

The jokes are sicking scotch

Next, you can proceed to the electrical connection. Connection diagram is presented in the photo.

Electrical circuit for connecting a film warm floor

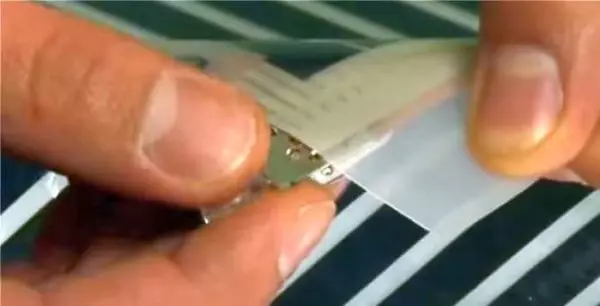

First, bituminous insulation (comes in the kit or purchased separately) closes the tires in places of cuts. Take a piece of insulation, remove the protective coating on one side, apply so that the entire surface of the tire is completely closed, including contacts. Half bend on the other side and carefully pressed.

Insulating a slice of tires

From the side, contacting clips are installed close to the thermostat (it is included, but you can buy a wire separately or solder to the copper bus). Contact consists of two plates. One roll on the tire, second under the film.

Installing contact plates

The installed plate is crimped with passups. Check the strength of the installation, slightly pulling the contact.

Cut the contact with Pasaltipa

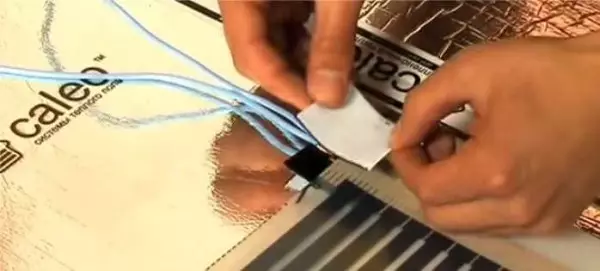

We take the electrical wires with copper veins, according to the circuit above insert one or two conductor in the clip at the contact plate and also crimp the passatages. If there is soldering skills, it is better to drink compound.

Crush inserted wires

The next step of installing the electric film floor is insulation of the connecting places of the conductors. For each connection there are 2 plates of bitumen insulation. One is placed from below, the second one. Also follow the tires and contacts completely closed.

Insulation places connecting strips

Also the installation of a heating floor temperature sensor is also different. It is simply glued to the black (carbon) strip of a piece of scotch.

Attach the floor sensor to the carbon strip

So that the sensor is not shaking, the window is cut in the substrate.

Cut the window under it in the substrate

The same windows are cut under the injured contact plates and wires. It is necessary that laminate or linoleum lay exactly, without bugs.

Cut the windows under contact plates and wires

Locked the wires, we stick with scotch.

We put the wires, we put in from above scotch

Located wires

Conductors connect to the installed thermostat (the installation is no different from the above), we test the system, exhibiting the heating no more than 30 ° C. Checking whether all bands are heated, there is no reason or the characteristic smell of melting isolation, warm under the turn off.

Next, the procedure depends on the type of flooring used. If it is a laminate, you can immediately spread the substrate and start it at its laying. Only the substrate must be a special, intended for a warm floor, like the laminate itself.

If there is a linoleum to fit, a dense polyethylene film rolls onto the film electric warm floor.

Film fit

From above laid a rigid base - Phaneur, gypsumless sheets. They are attached to the self-tapping screws to the floor, only at the same time it is necessary to follow in order not to get into the tires. And from above, you can already put carpet or linoleum.

Video lessons on laying

Article on the topic: Sewing lambrequin for curtains - the fastest way!