Before construction or in the process of capital repairs, the heat insulation of overlaps is inevitably arise. Painting plates for floor are modern thermal insulation material.

The structure of the sheets is such that it is possible to carry out work on any type of overlap and even right on the ground. Consider the properties of the fastener, how to insulate the floor by polystyrene, methods of laying sheets and situations in which this material will serve as perfect protection against freezing.

Types and texture of sheets

The plates of this thermal insulation material are made by a standard width of 0.6 m and a length of 1.2 m and 2.4 m. The plate thickness varies from 0.02 to 0.1 m, therefore, depending on the needs and possibilities for increasing the height of the sexual cake, you can find a suitable insulation.

In the production of plates, manufacturers withstand clear sheet dimensions, which makes it easy to mount the material. Determining how to insulate the floor by penplex, it is necessary to familiarize themselves with the technical and operational characteristics of various material stamps.

Any brand of foam insulation has a thermal conductivity of 0.3 and is allowed to use in temperature from -500c to + 750c.

Specifications Property

| Characteristics | Penoplex 31. | Penoplex 31s | Penoplex 35. | Penoplex 45. | Penoplex 45S. |

|---|---|---|---|---|---|

| Density (kg / m3) | 28-30.5 | 25-30.5 | 28-37 | 35-40 | 38.1-45 |

| Compressive strength (MPa) | 0.20 | 0.20 | 0.21 | 0.41 | 0.5. |

| Better tensile tensile (MPa) | 0.25. | 0.25. | 0.4. | 0.4. | 0.4-0.7 |

| Water absorption per day (%) | 0.4. | 0.4. | 0.4. | 0.4. | 0,2 |

| Fire resistance category | G4 | G1. | G1. | G4 | G4 |

Polystyrene foam is well insulates warm and pushes moisture

Floor polystyrene for floors - modern technological building material that combined the properties of foam and plastic. Due to its specific cellular structure, the Penoplex perfectly retains heat and actually does not absorb moisture.

From similar sheet heat insulators, its distinguishes high density and strength on the break. The strict structure of the plate allows you to create frameless insulation of the floor by polystyrene foam.

Article on the topic: Country toilet do it yourself step by step

Advantages of insulation Painoplex

Life of this type of insulation at least 50 years

With proper laying, this material will not only put the plant penetration barrier inside the room, but also will increase the sound insulation level. Also, the advantages of the insulation of sex by penplex can be attributed:

- Practically zero water absorption. This property allows the use of material in rooms with high levels of humidity. In addition, serves as an additional layer of waterproofing.

- The different thickness of the insulation makes it possible to use the material both at the construction stage and for work in the operating rooms: an additional layer of thermal insulation is not "eating" the height of the ceilings.

- In the manufacture of material, components are used, sustainable chemical and physical influences. The service life of the leaf insulation is more than half a century.

- The stiffness of the material is provided with a shallow cellular structure and allows you to create prefabricated plates with high mechanical strength, while the material is quite simple in processing.

- The insulation of the floor by extruded expanded polystyrene can be made directly on the ground, without pouring the concrete slab.

- Ecology and harmlessness.

The negative properties of this material include high cost and some exposure to high temperatures. Depending on the additives, the Penoplex may challenge from high temperatures, for example, from sparks during welding.

The temperature for the occurrence of combustion should be higher than 2000s. This indicator is necessarily written in a certificate of conformity issued to each batch of goods.

Installation of thermal insulation material polystyrene foam on the floor is possible for any type of foundation, including:

- Concrete or cement-sand screed, slabs of overlaps;

- the rammed ground without a screed device;

- wooden floors;

- When pouring the system, a warm floor.

Each methods have some specifics, but at the same time work under the power to produce any person with primary construction skills.

Laying on concrete

Before laying the insulation layer, align the surface, remove the bumps

The insulation of concrete floor is polystyrene begins with checking surface levels.

Article on the topic: Separation measurement

Plates or screed should not have cornpieces and noticeable cracks.

Apparent defects are better corrected, the bay leveling layer.

If the surface of the overlapping is in good condition, it is enough to clean it from garbage, dust and impregnate deep penetration with primer.

When carrying out work on the basement, above the basement or nation between the base and plates of the fastener, it is better to add waterproofing film. There is no need for this layer on high floors.

Plates can be put on glue

Further, the plates are placed on glue, while it is necessary to check the surface horizontality. Neighboring rows of plates are mounted with a displacement of ½ sheet. The surface of the polystyrene foam is closed with a film, the reinforcing mesh is stacked and the screed is poured under the finish coating.

A similar sequence when system is a warm floor. The heating system is placed on the reinforcing grid, and then the screed is poured.

At the same time, the waterproofing film is covered with the allen on the walls and is sampled by a damper ribbon. It will not give a collapse of the decorative layer when heating floors.

Wood-based installation

Floor insulation Penoplex in a wooden house can be carried out on an old base if it is in good condition. To do this, open a couple of boards and appreciate the status of the lag. The surface of the wooden base must be smooth and treated with primer. Since the tree is easy absorbing material, then it is necessary to progress the surface at least than two layers.

The heated base is stacked polystyrene foam for floor insulation. For fixing plates, glue is used, the seams are proper.

The entire layer is closed with a film, on top of the wooden sheet material, for further use as the basis for the finishing finish.

At the same time, it is important that the plates of all layers and materials fit with displacement relative to each other.

If you had to replace lags, then use the Penoplex as the insulation between the soil and the floor is not economically appropriate. In this case, it is better to choose a cheaper material, since the main quality of the fastener: stiffness and waterproofability in such a device will not be involved. For details on how to insulate the floors from wood, see this video:

Article on the topic: One-room apartment design for a family with a child

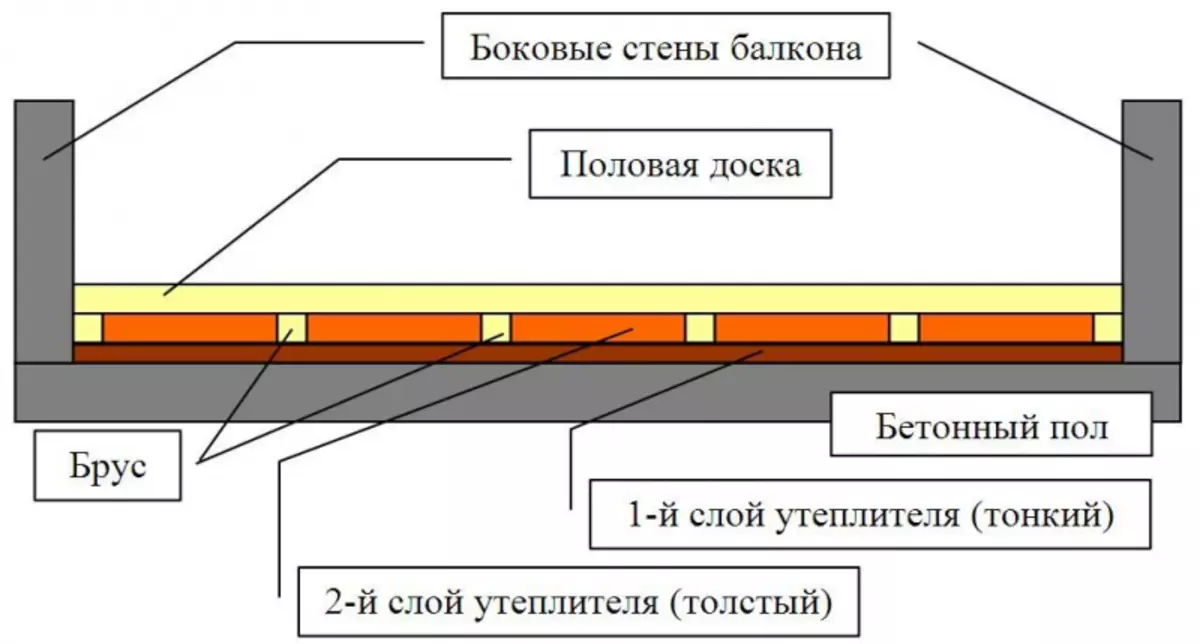

The device of a warmed floor

The exception is the device of floors on the lags in the house on the pile foundation. In this case, the insulation of the wooden floor by penplex is as follows:

- Installation of rough overlap;

- Laying the waterproofing film;

- Placement of sheets of polyplex with shift shift;

- fixing by self-drawing of the insulation layer;

- planking gaps between foam sheets;

- installation of vaporizolation;

- Laying of pine floors on lags.

Open ground

This thermal insulation material is remarkable by the fact that if necessary, it can be stacked directly to the soil. To do this, its surface should be dry and well tumped. About Tom, CC correctly do and insulate the floors on the soil, see this video:

When designing such a floor, it is worth considering that the thickness of the cake of the coating will be about 0.6 m.

Phased work is carried out in the following order:

- On the rammed soil pillow the pillow of a crushed stone with a thickness of about 0.3 m and tamper.

- The layer of fine-grained sand is dumbling and compacted to 0.1 m.

- On top of the sand, plates of the maximum possible thickness are stacked. There are no possibility to purchase thick sheets, then thin plates are stacked in two layers perpendicular directions. The sheets of the top layer can be glued together.

- Docking seams suture with metallized scotch, Penoplex cover the waterproofing film.

- Over the waterproofing, launch the fiberglass mesh for additional reinforcement.

- Fill the screed with a thickness of at least 0.05 m.

The composition and characteristics of the screed depends on the finishing coating. In any case, pour starts from the opposite corner from the door. When laying fasteners on sand, it is better to use slabs with docking grooves on ribs.