If you plan to use a parquet board, linoleum or carpet, then for these materials, you need to equip a reliable and even draft base, the plywood is able to help it, which can be put on the surface of the concrete floor. If you stick to the screed to the screed, then this will allow the budget version of the floor alignment in a short time. Plywood will hide any irregularities of the concrete base surface. This plus, characteristic of the material, is not the only thing, plywood has also excellent thermal insulation characteristics, so it will insulate the concrete floor with low thermal insulation characteristics.

The floor of plywood is popular due to the simplicity of installation and the small cost of the necessary materials.

Preparation of the surface before starting work

Laying of plywood cloth should be made on an even base. This requires advance control of the floor horizontal before starting work. If the height differences exceeding 2 mm were seen, then the screed must be filled additionally or and is reused at all. The laying must be made after complete drying of the solution, which can go about 45 days. The screed must have a certain level of humidity, to check this characteristic to the surface of the floor, a polyethylene film should be formed, the minimum size of which is 1x1 m, along the edges, the material you need to press the hard objects. After 3 days, the film can be checked for evaporation on its inner surface. If the condensate was not formed, then you can start the disconnection of plywood and subsequent laying.

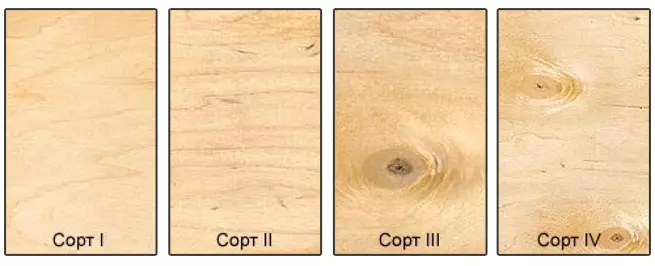

Grade plywood.

Plywood canvas are characterized by a disadvantage, which is called internal voltage. This can cause the material of the material is not always smooth. This feature should be considered before the start of laying - the material is to be cut into small blanks of minor sizes, which will allow you to equip a flat floor. It is preferable to cover the material with squares with the following dimensions: 0.75 or 0.6 m. The presence of seams between the canvas will be compensated for by changing the linear dimensions of sheets.

Laying plywood should be preceded by analyzing the condition of the material after cutting.

The canvas should not have damage in the form of chips and bundles. After cutting, the sheets can be put on the base surface. Now you can mark the sheets that should be corrected and adjusted under certain areas of the room, among which: niches, corners and protrusions. The rough styling of the material will create the drawing, which will be made the final stuffing material.

Article on the topic: Sliding doors to the balcony: Selection and installation

Existing plywood sizes.

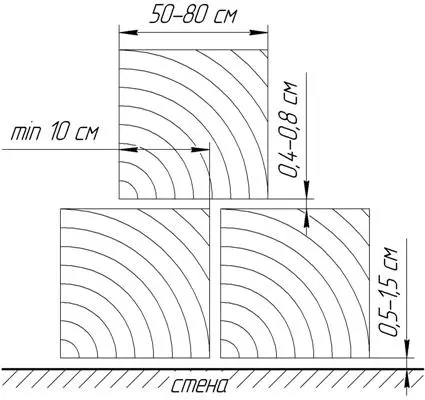

The laying process should be made with the provision of seams, different types of which should be given a certain width. Thus, there should be widths from 0.1 to 1 cm between the next positions of the seams, whereas between the coating and the seam wall, it is necessary to give a width from 1.5 to 2 cm. Sheets before final stacking should be numbered, which will allow Correct them correctly in the process of sticking.

Floor treatment primer

If you think about the question of how to stick to Phaneru, you should know that it should be used for this special composition, which should be applied in a tandem with a dowel-nail. Laying plywood can be produced on a water-based composition. As an alternative solution, mixtures on the basis of solvents or on the basis of two components will perform. The most secure person is a water-based composition. In the process of use, it does not spread the smell, and its preparation involves the use of pure water. This mixture is used in the role of primer. However, it is necessary to take into account that the use of such a composition implies rather long drying. If you decide to stick to the Fanoire, which is based on a solvent, then to produce additional impregnation of the screed of the primer. In addition, work will be accompanied by a steady unpleasant odor. But it will dry up the maximum maximum for 5 days.

Plywood laying diagram on the screed.

If laying of plywood should be carried out in a short time, it is recommended to use two-component glue. And after 24 hours, you can proceed to grinding the surface of the base. In some cases, this composition in a tandem with epoxy primer is permissible to use on a concrete basis, which did not have time to dry.

Two-component glue, in contrast to water-based compositions or solvents, does not imply additional use of a dowel-nail.

The laying process is preferable to produce using adhesive compositions of arthelite and Uzin brands.

Tools and materials necessary for work:

- toothed spatula;

- Heavy roller;

- glue;

- Dowel-nails;

- plywood;

- Olife

A toothed spatula is used to apply glue.

Some masters are fixed to Phaneur to the screed, pre-not priming the base. However, it is not necessary to relate skeptically to carry out this process, since the primer is able to eliminate even the most minor dust particles, to make the basis the most durable, increase the adhesive characteristics of the materials, lower the amount of glue used. In addition, the priming can prevent excessive humidity.

Article on the topic: Beams on the ceiling do it yourself: Wooden, polyurethane, drywall

Laying plywood should be made immediately after the completion of the process of priming a concrete base.

Laying plywood sheets

The distance between the plywood sheets should not exceed 0.4 mm.

Before sticking to the fane to the floor surface, it is necessary to initially mark the location of the holes at the base corresponding to the markup, which is to be done on the blanks of plywood. Next, in the concrete screed, you need to equip holes on the markup. Now you can proceed to applying glue on a concrete base, for which it is necessary to use a toothed spatula. On the layer of the composition you need to put a plywood sheet, and after riding a sheet with a heavy roller. The canvas should be additionally strengthened by means of screws and dowels. The same technology should be applied to laying all subsequent plywood sheets.

Phaneur should be stacked on a layer of composition, the thickness of which should vary in the range from 2 to 3 mm.

The material must be drilled for fasteners, retreating from the edge of the canvas for 2 cm, while the step between the fastener should be equal to the distance of 15-20 cm. In the phaneer you need to scroll holes, the diameter of which will be so that the fasteners could be drown in the body of the workpiece Hat.

Final Processing Bar

Faneru after laying must be pasted, for this you should use a special grinding machine that has a rough emery coating. After this process, the plywood should be perfectly smooth and smooth. The floor should be deprived of the errors, which in some cases may appear in the vehicle. Laying plywood does not always allow to get the surface without drops of heights between sheets, these problems also allow to solve the grinding.The evenness of the laying of plywood can be checked with the help of a rail, the length of which is 2 m. After laying the rule on the floor surface, it will be possible to determine whether there are height and slot drops. If between the floor and the lower surface of the tool were seen, the width of which exceeds 2 mm, the work was performed poorly. And if the gaps within the norm, then you can start laying the finish coating on the draft base.

Recommendations on concrete loan plywood

An waterproof plywood can be laid on the tie, which is indicated by the Abbreviation FC. In its composition, wood veneer, which gluits the composition on the basis of the resin, there should be no phenol in them. Such plywood is quite widely used in the space of residential premises. Laying plywood of unwanted type (NSH) provides for the need for grinding after the installation is completed. The material can be laid on the screed, which is polished only on the one hand. It is recommended to fasten the plywood, the thickness of which is in the range of 1.2-1.5 cm.

Article on the topic: Circular shower - to increase the immunity and beauty of the skin!

Sheets on the screed must be laid with some displacement, avoiding the docking of four seams in one place. The screed before laying a draft coating should be cleaned from the formed construction waste, which appears after the implementation of putty, painting and other works. Repair dust from the base is more efficiently possible by an industrial vacuum cleaner.

Primer or primer composition on the screed should be applied with a wide brush or roller. To the tie, you need to strengthen the Phaneur Samors, the length of which is longer than the thickness of the base 3 times. Place fasteners when fixing plywood to the screed need not only around the perimeter of the canvas, but also diagonally.

A layer of waterproofing can be laid on the screed, which can perform dense polyethylene, pergamine or analogues of these materials. It is permissible to put a thin polyethylene substrate under the laminate on the screed. Its cost is not so high and varies ranging from 15 rubles per 1 m2, and the thermal insulation this material provides excellent.

Before laying plywood on the tie of the canvas, it is necessary to cover the oil into several approaches, the minimum is 2 layers. At the same time, special attention should be paid to the ends. Thus processed sheets will not be deformed.

After Plywood has been strengthened to the screed, it is worth leaving it for drying, after it can be seized and protected by a substrate, it is desirable, it must be made of waterproofing material. On such a cake perfectly lay out the piston coating.

Not in all cases, the rigid fastening of plywood to the screed is appropriate. It is not necessary to cut a solid canvas on excessively small sheets, which is especially concerned with the premises of urban apartments, the area is not so great. This will only increase the scope of work.

If after laying the cloths on them it is planned to be stuck thin linoleum, the seams are recommended to fill with a sealant. Its plasticity will not be a hindrance for thermal expansion, and the seams will not be suggested.

Plywood can be an excellent solution if necessary, in a short time to level the concrete floor surface for further laying of the finishing coating. Such works are not only unemployed, but also will not cause large financial investments. And even the master who has no experience in this area will be able to align the technology described above.