Table of contents: [Hide]

- How is the drawing bed made with their own hands?

- Dimensions of manufactured design

- Tools and materials that need to make a bed do it yourself

- Approximate calculation of the necessary materials

- Bed manufacturing process

How is the drawing bed made with their own hands?

Today, people often are often trying to save on acquisition of various furniture. Beginner masters are trying to make interior elements on their own. One of these elements is a bunk bed. Make a similar design with their own hands at all. To do this, you will need to have only initial skills and know what a retractable bed should be as a result.

Bunk bed is a replaceable thing in the family, where two and more children. Such a bed also helps to save space in a small room.

To date, bunk retractable beds are considered popular and fashionable. Almost every child wishes to see such a design in her room. This is due to the fact that such a bed not only saves space (the retractable elements allow you to put in them, for example, clothing), but also makes the children's room more comfortable and cozy.

Children sleep on such beds with pleasure, besides in addition, they become friendly. All because they need to negotiate who will sleep on the lower tier, and who are on the top.

Back to the category

Dimensions of manufactured design

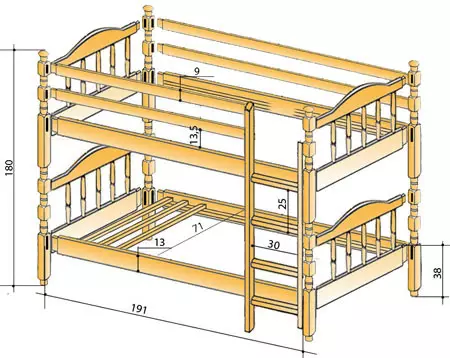

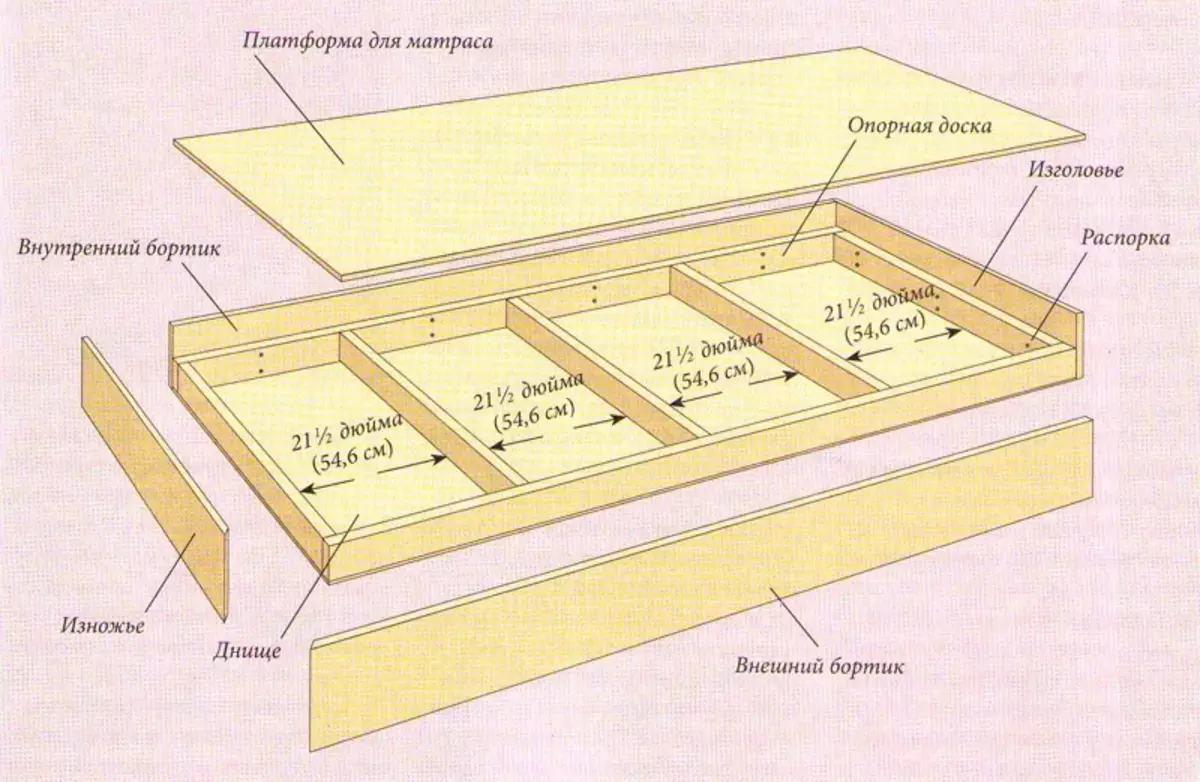

Bed frame circuit.

Before you start doing a bed with your own hands, you need to think about something. First you need to decide on the future location of the manufactured design. Next, you need to think about where the staircase will be in the design. After that, it will be possible to understand what sizes will need to make a bed with your own hands.

It is worth taking care of the size of the beds of the first and second tier. In length, the size of the bed must exceed 80 mm, and in width - by 100 mm. From the side where the staircase will be located, it will be necessary to add 45 mm to the sizes. Regarding the bedroom should be said that the sizes of the mattress are approximately 1800x800 mm. Its thickness is 200 mm.

It is necessary to think over the height of the bed, which is planned to be made. In this case, it will be necessary to proceed from the height of the ceiling in the room, which is planned to have a design. It is necessary to consider the fact: the higher the child will be, the harder it will breathe. In addition, the children love to jump on the top tier, in connection with which there is no need to make a bed very high.

It should be remembered that the distance between the sleeper 1 of the tier and the frame 2 of the tier should not be too small. In order to determine the optimal distance, it is necessary to plant an adult for the first tier - it should not be drunk his head into the frame of the second tier.

Under the lower tier will be located retractable lockers, therefore should leave a sufficient place.

Back to the category

Tools and materials that need to make a bed do it yourself

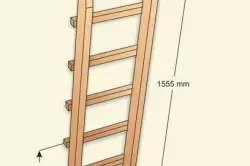

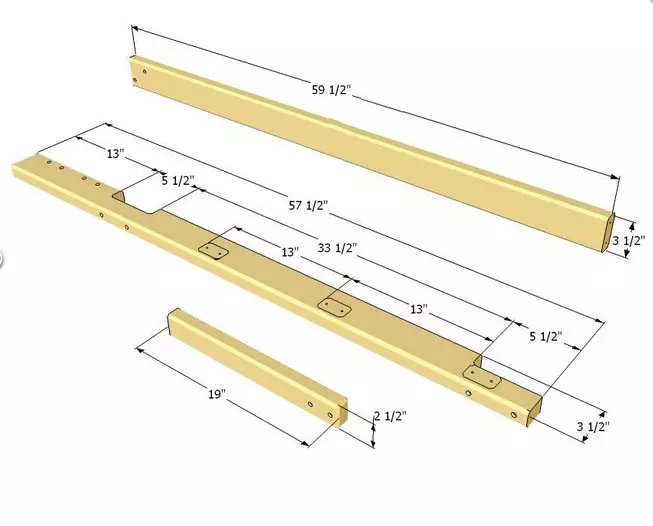

Scheme of the size of the stairs.

You need to know that the bed can be made from wood or from chipboard. In the latter case, the design will have 2-3 times greater weight, but can do it much cheaper. In order to simply find building materials for the manufacture of such a design with their own hands, you will need to have the planks of the following dimensions: 18x140 mm, 40x140 mm, 40x80 mm and 30x30 mm. It is not recommended to be attached to a certain length. It will take to paint, what parts and in what quantity it will be necessary to have to make them from the boards in the future.

Drawing of a bunk bed.

It should be noted that it will also be needed by a person who has a certain experience in this case. From wood, it is difficult to make products enough, and not everyone is under force. However, if we replace wood, for example, on a laminated chipboard, everything will become much easier. This will almost completely eliminate the novice wizard from complex operations with their replacement for incoming.

Furniture that is made from a laminated chipboard, in appearance and strength practically not inferior to structures that are made from wood.

The foundation that will lie under the mattress (2 sheets of plywood 1000x1900x10 mm), component parts (3 steel pipes with PVC coating), various fasteners (decorative washers-plugs, screws 3.5x40 mm), glue.

Before performing a bed, boards, of which it will be manufactured, it is necessary to withstand in the room for 1 week. It will be needed in order for humidity and temperature to be the same as in the room where the design is planned. Thus, the bars and boards will not fight.

Wooden board is based on. All items will need to handle with alignment, grinding and coloring. For these purposes, workshop and high-quality equipment may be needed.

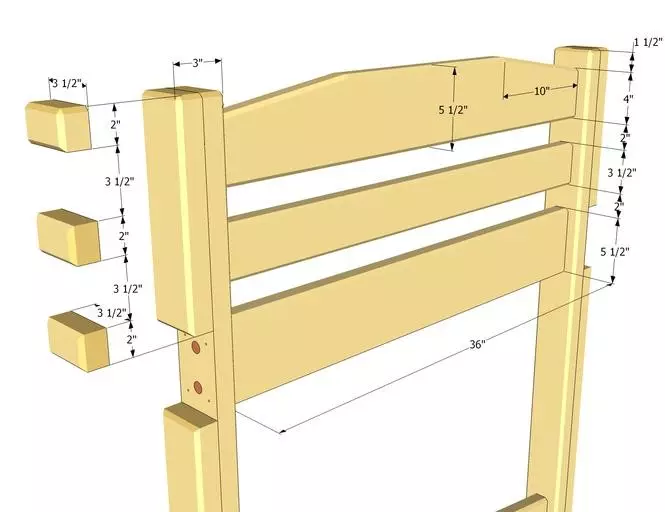

Bed back sizes.

Tools that need to make a bed do it yourself:

- milling machine;

- screwdriver;

- drill;

- building level;

- roulette;

- Ordinary hacksaw either drank;

- Magnet or metal detector.

Back to the category

Approximate calculation of the necessary materials

In order to make the sun bed on which the mattress will be located, the board of 18x140 mm will be needed. On each tier is placed approximately 10 boards.

This quantity will be enough to jump the maximum possible number of children on the mattress.

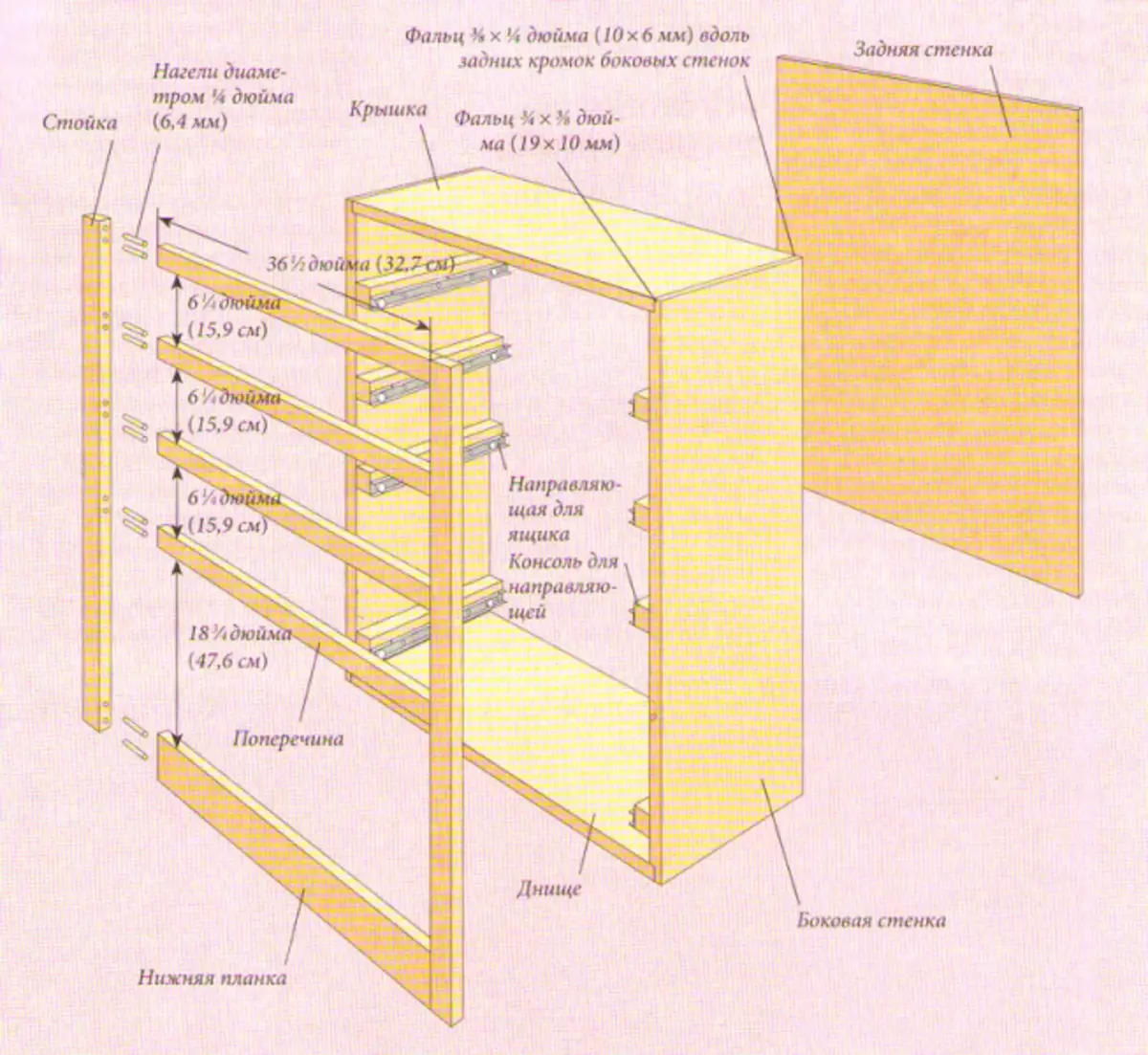

Bunk wall diagram.

The width of the bed location is 800 mm. It will take a little from it, so that it does not have a sledgehammer to hammer and increase the number of boards by 2.

The bar on which sun beds will be located, has a size of 40x40 mm. For the manufacture of side and ladder, you need a board of approximately 40x90 mm. In this case, the number of parts depends on the location of the ladder and the presence of a side on the lower tier.

In order to give construction strength, you will need to have a 40x140 mm board. It should be placed for tightening the bed throughout the perimeter.

In order to accomplish the approximate calculation of the required amount of materials, values were given.

Back to the category

Bed manufacturing process

Bed pallet diagram.

Material for the manufacture of bunk retractable beds is recommended to choose ash. A tree that has a beautiful texture does not have to be painted. You can simply cover it with a hot oil. The texture can be opened with the use of furniture varnish, but it is not recommended to do this, because there may be a more natural matte color.

In order to make the side panels of the cabinet, front panels of drawers and the cabinet door, plastic should be used, which is fixed with casein glue on plywood. If there is no possibility to purchase plastic, it makes sense to try to crack the faeer with a cloth.

All cabinet connections and a frame frame are assembled in a spike on casein glue. Cabinet and racks have longitudinal grooves in which rear and side panels are inserted during the assembly. The grooves for 2 arrival are selected by a disk saw. Steel corners with shelves, which have a width of 40 mm are attached to the longitudinal brushes of the power frame with screws. They will rely on the lower and upper magazine panels, which are made of plywood with a thickness of 10 mm.

Scheme side of bed.

So that the top panel does not be bombed under the weight of a person, it should have rigidity ribs from the rails, which are glued on the underside of the plane and fasten with screws for reliability. The lower panel rests on the bars of drawers, in connection with which it does not have additional ribs.

The mattresses will suit standard, purchased. Under these makes sense to lay a layer from the Falone Sheet, so that the bed is softer.

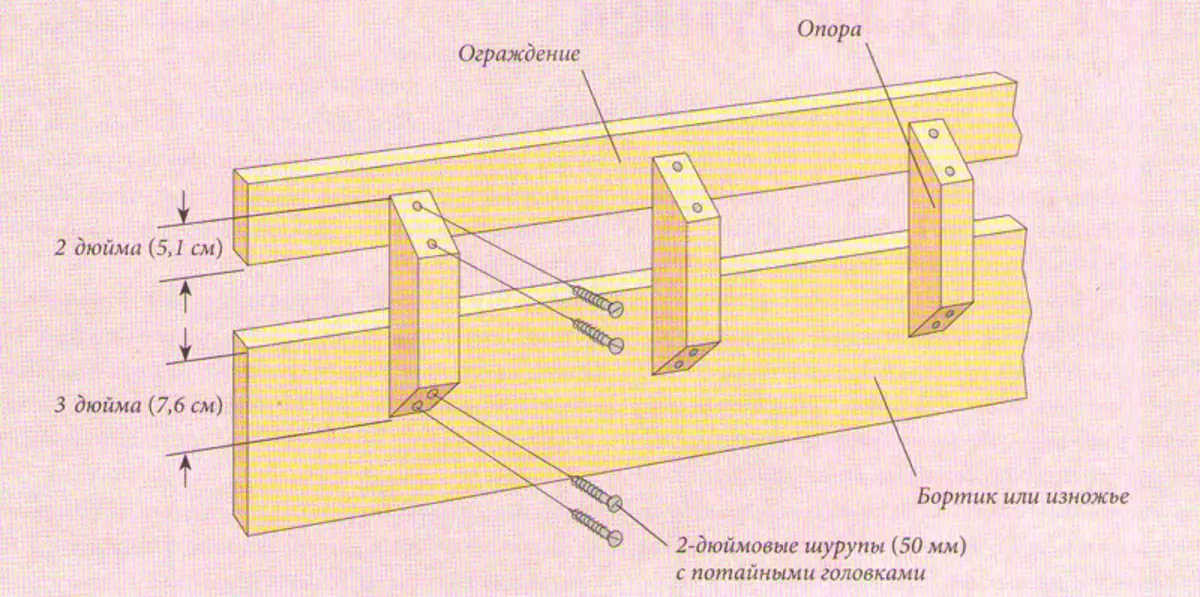

The bed is recommended to be installed close to the wall. In this regard, on the one hand, it is not necessary to make fences. From the outside of the bar, the fencing of the upper tier is mandatory. They are fixed in one end to the stacks of the locker in the spike, and the other end is screws to the ladder.

The staircase is made of 2 racks that have a cross section 70x30 mm, as well as 3 steps having a diameter of 30 mm and made on the lathe. The staircase joins the bed under a slight slope. In its lower part, it is fixed to the floor using steel corners.

In the closet you can provide a shelf for lingerie, and on the brass tube there is an opportunity to hang her shoulders for outerwear. On the back of the locker, on one of the rigidity rigs, you can position the furniture hooks. From the front side, the locker door is covered with plastic and fixes to the cabinet on 2 homemade bends of steel sheet, which has a thickness of 3 mm. Sheds are painted with black nitroemal.

Planks for a bunk bed ladder.

The door flush enters the opening of the cabinet frame. It is going as follows. A frame of a small thickness is made of a frame that has a size of 2 mm more than the opening under the door. For the inside, the plywood sheet is recommended to take a thin, with a beautiful and smooth surface. The substrate under the plastic (sheet of plywood) is better to use thoroughly, and the billet from plastic should be cut out several large sizes.

All this must be missed with casein glue and assemble in the package. In order for the construction during the assembly, it is possible to grab the wooden parts with small nails. On top of the plastic should be in several layers, paper was laid, after which the rails. Further, the entire package is clamped with clamps and is withstanding under the press during the day. Door ends after gluing need to be treated with a planer to the required dimensions.

A cornice with hooks for curtains screwed into the corner of the steel of the longitudinal external bar in the lower part of the upper tier. From the outside of the sidebar of the locker (at the head of the head), an electric ceiling globar plane is installed. The wiring is output from it into the closet, after which from the locker to the wall and to the nearest outlet.

Lowering drawers are collected from 4 boards each. Between themselves they are connected in a spike type of a swallow tail. The bottom of the plywood, which has a thickness of 3 mm, when assembling should be inserted into the grooves of the walls of the boxes. Facial panels made of 10 mm plywood with plastic glued on it are made separately. The panels are attached to shurus boxes, which are screwed from the inside of the box. At the same time it will be necessary to choose the length of the screw in such a way that he can keep the panel well, but did not come through and did not damn the panel cladding.

On the sidewalls of the boxes, steel rods are installed, which are bent from the steel strip having a thickness of 1 mm. Boxes will go to the corners on the metal plates. In order to the extended position, the box did not flip down its front part, the restrictive cheeks are installed at the ends of the poloz, which exclude such an opportunity. It is quite difficult to bend a 600 mm length of 600 mm, therefore it is possible to use finished corners.

Article on the topic: Wooden eaves for curtains: species and features