Materials such as laminate and linoleum are most often used as floor coverings. They are distinguished by excellent appearance, durability, resistance to many types of impacts. In addition, the cost of such coatings is available for any budget. But they do not always cover the entire floor in an apartment or house by any one material. For example, linoleum is used for corridors or kitchens, and for residential rooms - laminate.

The transition between different types of flooring can be not only a functional reception, but also the design highlight of the interior.

So that the coating is attractive and seemed to be uniform, it is necessary to correctly process all the joints. Options for performing such works are several. You can apply special connecting planks or do without them. The selection of one or another variant depends on the decorative requirements, installation conditions of coatings.

Single-level and multi-level joints

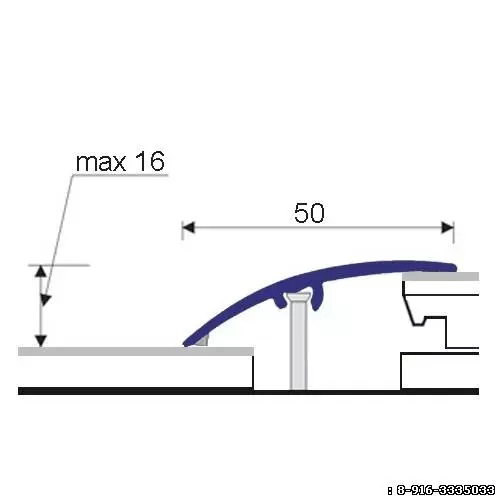

Fastening diagram of multi-level lighting

A single-level joint is the most attractive, the floor looks uniform, and the joint itself is not noticeable if not to use for this plank. To perform a similar mounting option, it is necessary to align the floor specifically for the data of the coatings, as the laminate usually has a higher surface than linoleum.

The joints can be both multi-level when coatings differ in height. But in this case there is nothing complicated, you can use special thresholds that allow you to connect two floor coatings with a height difference in one and a half centimeters.

The planks completely overlap the joint, the special design makes it almost imperceptible and very neat.

Planks and jacks for junctions between linoleum and laminate

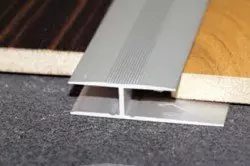

The most common material for the production of connecting planks is aluminum. This option allows you to imitate the surface of the parts for bronze, gold, either a tree, which significantly expands the possibility of decorating the floor covering. Most often on sale you can find 2 options:

A simple variant of aluminum clamp provides a reliable transition, but loses in design.

Anodized strips, which are resistant to external coating, are used for corridors, kitchens, hols.

- Conventional laminated planks can be used for other premises where they are not subjected to such strong loads.

In some cases, simple plastic strips are used, which are much cheaper. The surface of their laminated, strength and stability resistance is lower than aluminum. It is usually not recommended to be allowed to stick laminate and linoleum using such elements, especially indoors where elevated loads are observed. But they are indispensable when it is required to perform curved joints, a radius connection. Brass thresholds are considered the highest quality and durable among all, but also the cost above. The brass is not processed, it retains its natural color, but over time fades. This problem is easily solved, the bar is simply rubbed felt for the return of shine and color.

Connecting Plank Fastening Methods

All strips that can be used to design joints are different from the fastening method. You can choose any convenient option that is suitable for a specific situation. When delivered, manufacturers offer full kits for performing such fixtures. For example, for through-cut special self-tapping screws together with the planks.

The following types of fastening are applicable today:

The hidden fastening is carried out using a hidden groove, which is rolled out on the screwed screws.

Through. With this variant, the plank is superimposed on top of the connection of two floor materials, after which it is attached to the floor with the help of self-samples. Such an option is reliable, it allows you to fix the coatings as closely as possible, hide the clip.

- Secret mounting planks. On the back of such thresholds there is a special secret groove. The front part of the fastening strip is smooth, it has no holes. The installation process will be understood even a newcomer. A secret plank by self-drawing is attached to the surface of the floor, the outdoor material is reliably pressed. Pre-in the floor along the docking line drill holes in which the toxes are clogged. A secret plank should literally be attached to them until it stops, no gaps between it and gender can not be. It is required, since with shunters with a hammer during the fixation of the plank may simply break away either strongly deform. The top of the decorative top is installed on top. The linoleum and laminate shake should turn out to be united.

- Gluing. This option is not so often used, as it cannot provide the necessary strength. Most often used for floors with tiles, but it is still quite possible for linoleum. The attachment method is that the floor materials are connected in the required place, after which the decorative plank is simply glued with liquid nails to the floor. Instead of liquid nails, it is possible to use transparent silicone-based adhesive. This option applies mainly when the base of the floor is sufficiently loose, weak.

Laying without planks

The junctions between linoleum and laminate can be decorated and without special planks. This option is more expensive for the reason that the waste during the climb will be greater. When laying the material, it is necessary to ensure that the direction of the pattern and the boards coincides. In this case, the laying will turn out not only even, but also very attractive. Thinking through the direction must be in advance. For example, when laying in corridors or holles, it is necessary to provide for laminate boards to go along, not across.

Laminate without thresholds is simple, but the linoleum is almost impossible, as it is necessary to ensure the maximum mounting of the edges. For example, when docking near door openings will have to not only make a thorough and very smooth closure, but also provide fixation to the floor. Usually, silicone transparent glue is used for this. After the linoleum on the junction with laminate is glued to the surface, the slot is necessary between them to additionally pour these adhesive composition, but to ensure that it does not get on the outer parts. For this, the painting tape is used, which is first pasted on the joint area. After it is processed, cutting the knife on the junction. Care here does not prevent, the coating should not be damaged. The entire joint is filled with silicone glue, the tape is neatly removed.

For the connection of laminate and linoleum, various methods are used. Their choice depends on which material will be used for flooring to the floor, under what conditions it is carried out. For example, the most popular is the connection with the help of planks that are simply attached to the junction. There are options when the joint is simply attached to silicone transparent glue. The last method is more costly, but it allows you to make a connection almost uniform.

Article on the topic: How to pour a warm floor with concrete - step by step instructions