Floor insulation with foam is greatly popular with the effectiveness of the work performed and the result achieved through their conduct.

Polyfoam for floor insulation or polystyrene foam is used for many years as a material that helps keep the temperature and heat in the room, when placed on walls and ceilings, outside and inside buildings.

The floor is a surface, on the quality of the insulation of which the temperature largely depends on the entire room, so the floor requires high-quality insulation using modern materials.

What foam plastic happens

Polyfoam has a high thermal insulation capacity

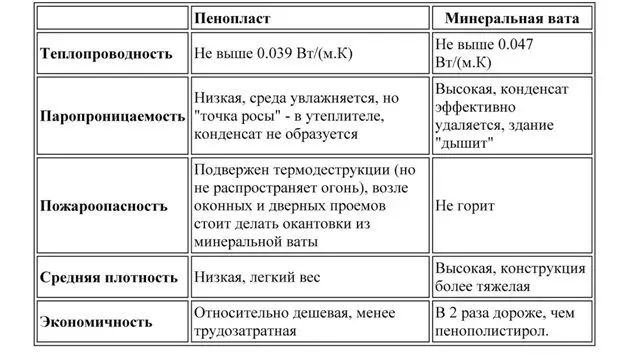

Thinking over how to insulate the floor of the polyfoam, it is worth carefully examining its features and advantages of this raw material. It refers to the number of high-quality thermal insulation materials.

Polystyrene foam is often used to arrange warm floors. The insulation of the floor by foam under the screed can be performed with their own hands without attracting qualified masters. This operation is distinguished by slight installation, availability of material and ease of implementation.

Foam leaf can be adjusted under any size

Polystyrene foam is white slabs that can be easily damaged mechanically. The insulation of the floor by foam under the screed is popular because it:

- features a high degree of elasticity;

- has a higher thermal insulation capacity;

- very easy;

- just cuts.

With the help of a conventional knife, the sheet gives any desired shape and size. Polystyoltilol quickly comes in disrepair under the influence of ultraviolet rays and therefore the insulation of flooding floods is particularly popular.

Before purchasing the required amount of thermal insulation material, it is necessary to clarify its technical characteristics and first of all make sure that the desired foam brand is selected, characterized by characteristic properties and qualities.

The insulation is placed on a layer of waterproofing

The main difference between the plates is the density from which the polystyrene brand depends. The density level must be taken into account with the performance of such works as a screed of foam.

Article on the topic: Cookpover repair: Main types of breakdowns

Floor screed with foam can be concrete or cement-sand. It is capable of becoming a reliable protection for the insulation, which is easy to damage, and which will have to withstand quite high loads during the operation of the floor covering.

A variety of insulation foamflast

The insulation of flooding floors is performed on various bases. It can be:

- concrete;

- wood;

- Clean soil.

Polyfoam for the floor under the tie is high-quality thermal insulation, and if the work is carried out on the ground, it is necessary to lay the plates of the highest density.

Under the tie laid plates with a density of at least 15

The foam for a warm floor is a plate, the density of which is achieved 50. The minimum value of the density characteristic is 15. The foam plates are laid with a density of at least 35.

Laying foam plastic under the tie of the floor is carried out in accordance with a certain technology, which has some distinctive features, depending on which the base is constructed.

The screed on the ground is constructed in private houses located outside the city. In this case, qualitative preparation of the foundation will be required. The surface should be dry and absolutely smooth. About how to make a screed on expanded polystyrene, look in this video:

The polystyrene foam is placed on the basis consisting of several layers:

- The first layer is rubble;

- Second - sand, carefully tumped;

- Then the waterproofing, which uses a polyethylene film, laid by the brass, or rubberoid, which is lined with the same way.

Shoots between plates close up by mounting foam

By choosing your own waterproofing option, you can start it with its construction, and then to laying the plates of foam.

The slots between the sheets are filled with the mounting foam, then linked the second layer of waterproofing material and proceed to creating a screed that creates a firming layer.

For this, the rolled waterproofing is performed by reinforcement, laying the grid, the rod thickness is 5 mm.

Lighthouses are put on the grid, which use wooden bars. The first layer of screed with a thickness of no more than 2.5 cm is poured, checking its penetration under the grid and continue to fill the solution.

Wooden floor insulation is distinguished by the fact that before starting work, it is necessary to check the base itself for damage, fungus or mold.

Article on the topic: How to connect the fan in the toilet to the light bulb?

The insulation in the form of polystyrene is laid or directly on the wooden flooring or on a layer of rubberoid used as a rolled waterproofing.

Surplus of the mounting foam are cut after frozen

The overlap has many slots especially in places of contact with walls, therefore, high-quality hydro and thermal insulation is required. Now you can:

- lay the plates of expanded polystyrene;

- fill the seams and gap by mounting foam, cut off its surplus after frozen;

- To stipulate the entire surface with a plastic film with an overlap on the walls and suture the seams by building moisture-resistant tape;

- perform a reinforcing screed;

- put the grid;

- Fill the main screed.

Before proceeding with the pouring, it is worth the most firmly firmly fasten the sheets of foam with a dowel of nails. On top of the polystyrene, the second layer of waterproofing is lined, to which the metal design is placed and poured the screed.