It is no secret that uneven floors can cause damage to any interior. Laminate or parquet is pretty difficult to put on such floors. In order to avoid this, you will need a floor screed.

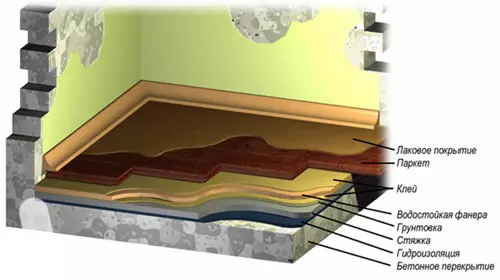

Scheme of semi-drying floor tie.

The choice of a screed depends on what time it is necessary to meet what costs are implied.

Everything can be done with your own hands.

Characteristics of semi-dry tie

It is such an alignment of floors, which implies the use of a rigid semi-dry solution, which is based on cement and sand. This method of film screed is notable in that it is characterized by increased strength (this strength is provided by a metal grid). It should be noted that such a screed has a number of advantages, it uses materials at an affordable price, but high quality. When the sand-cement solution is applied, it should be aligned with the rule and chop out. After that, no additional processing is required: it is not necessary to reveal it, not once again grind.

When the installation of a semi-dry screed is carried out, it is possible not to worry about the fact that the solution will be selected from the solution, which is clearly not referring to the inhabitants of the lower floor. You can make a semi-dry screed with fiberoloche, which is distinguished by durability and resistance to mechanical exposure. It is necessary to note the excellent heat and sound insulation characteristics of this screed. You can implement such installation using mechanized tools.

When does a semi-dry band screed apply?

- When there is no time for long-term repair work.

- When the overlaps do not differ in the thickness and there is a possibility that the lower floors will be flooded.

This type of screed is applied to such bases:

- In the houses of the old sample, these are wooden overlaps.

- In modern high-rise buildings, these are concrete floors.

Article on the topic: Shed for chickens for the winter: Build and warm the chicken coop

Device semi-dry floor tie.

For a semi-dry tie, the floor must be acquired by such materials:

- Sand (it should be carefully sacing).

- Fibrovolok.

- Cement.

- Water.

- Isolon or polyisol.

How to make a solution for alignment?

Technology of such a screed involves the use of high quality solution. From how qualitatively it is made, largely depends on how high-quality and reliable will be a screed.

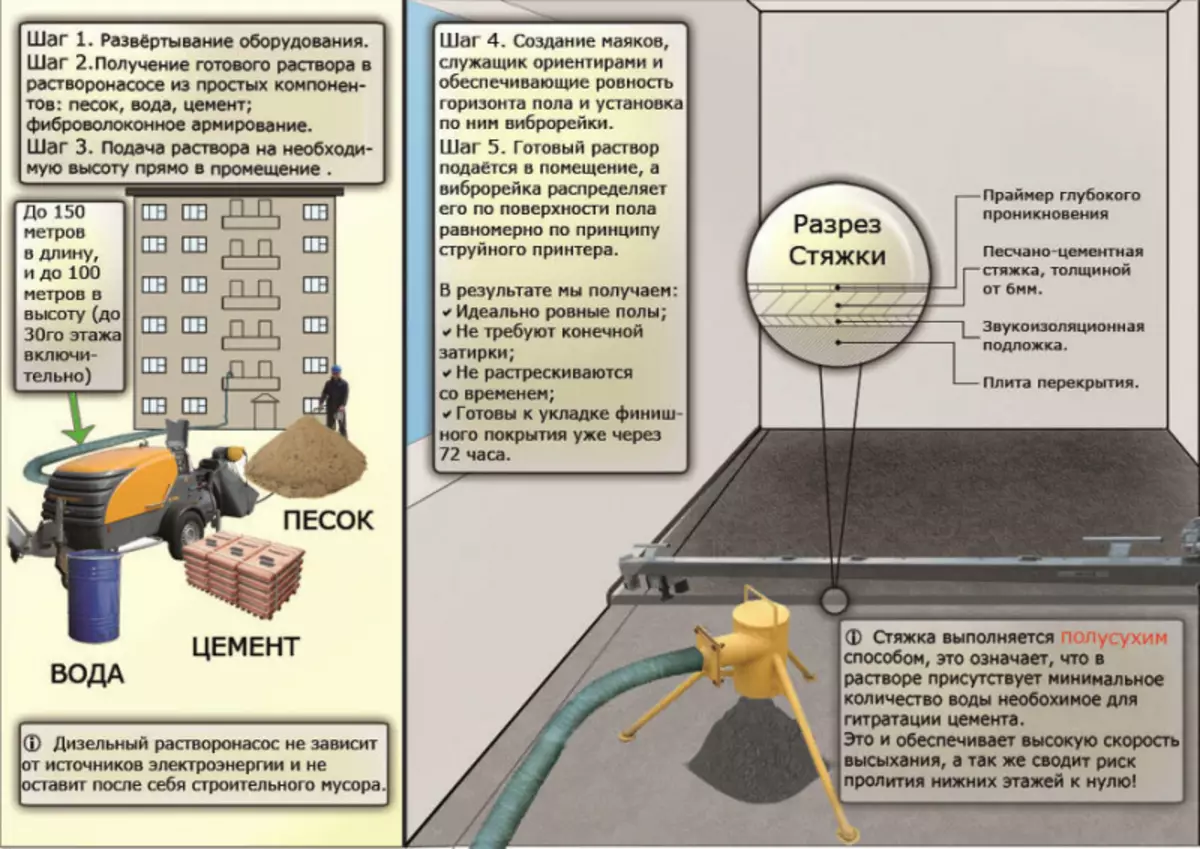

Scheme of production technology and laying semi-dry tie.

If a solution is used with the use of fiber fiber, then a 120 liter of sand, 50 kg of cement, 150 g of high-quality fibrovolok need to be filled into the pneumatic pump. If the room has an area of 20 sq. M, then 0.54 kg fibra will be needed. All components need to be mixed thoroughly (this is done at least 3 minutes). After that, water is added, the solution must be mixed again, with the help of the hose it is supplied to where it is planned to make a screed.

It should be borne in mind that for semi-drying gear, it will be necessary to purchase such tools:

- Pneumatic stepper.

- Grinding machine.

- Concrete mixer.

- Building level.

- Lights.

- Master OK.

- Thermalism.

- Putty knife.

- Tree from wood (you can use a grater of polyurethane).

Features of the technology semi-drying floor screed: first option

There are several options for this process, each of them deserves special attention.

Laying screed.

- First you need to carefully prepare the room, the remains of the former floors are removed, you need to sleep all the garbage.

- Now you need to proceed to the primer of the base. If there are deep pits, they need to be covered with primer (you can use special glue for this). The flaws can remain, but they must be smoothed in the maximum way. The primer is needed even in order to prevent the absorption of moisture by the base of the floor.

- There was a queue of laying the damper tape, which is especially important when the installation of warm floors is carried out. It should be borne in mind that the quality of the floor has an influence and temperature. The tape can be used ready, and you can cut a large roll that is made of foamed polyethylene. Thus, sound insulation and the screed is saved much longer.

- After the solution is cooked, you need to start it. First, the first layer is stacked, the thickness of which is 20 mm. It should be well tumped, and then you need to start laying the reinforcement grid. Slices of grid should be tied with wire, you can also cook. From above, you need to pour 3-4 cm of a semi-dry solution, then it's still thoroughly thoroughly. It should be borne in mind that if there is a fibrovolok in solution, then the reinforcement of the grid is no longer necessary.

- In order for the surface to be perfectly smooth, it is necessary to carry out work on the leveling of the flooded solution. The foundations are determined using a laser level. For high-quality performance, you must use beacons. In this role, it is possible to use profiles for drywall, they are placed in the solution, and then the surface is aligned (for this is used rule). To set the beacons from profiles, you need to spread the entire surface with lines. It is very important that the distance of such lines has no longer rules. Along the lines you should pour a pile of solution, it is for them that the profile should be put. Then the rule must be put on the profile (it should be a rebier). The extra material should be removed, the recesses are frozen, the solution is added again.

Article on the topic: Right wallpapers for small cuisine: 6 basic recommendations

Now the solution must be lost, the grater is used for this. After the solution slightly freezes, you need to remove the profiles, the remaining traces need to quickly pour into the solution, then everything is polished. Here you need to use a grinding machine.

Technology screed implies courting for her. When it is laid, you need to impose a film. This is done so that the screed does not dry faster than necessary. So that the cement stone is ripe, a humidity mode is needed, which should be provided during the day. The thickness of the screed should be about 5 cm. If everything is done properly, then after 4 days later, you can apply a floor covering, as a rule, decorative.

Second version (using reinforcement)

Such a screed technology is made using a solution and mesh made of metal, they fit on the layer of materials that have insulating properties.

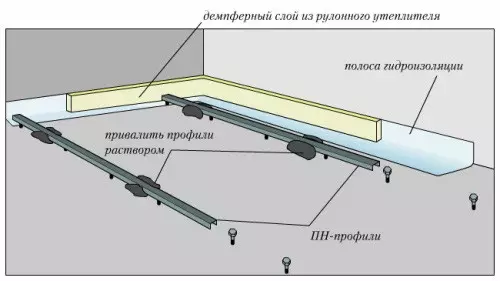

Installation scheme of lighthouses for a screed.

- It is necessary to carefully prepare the room, the remains of the old floor are not allowed.

- If there are irregularities on the floor, then they need to get rid of them. Sharp transitions, bulges and deepening are completely unacceptable. The bulges should be knocked down or believed, everything is wetted with water, then a solution or glue is applied.

- Sound insulation is very important. In the room you need to lay the ribbon (in its production it uses foamed polyethylene). The edge ribbon is fastened with liquid nails. Advanced is cut off, and the resulting edge provides sound insulation.

- In order not to be the receipt of moisture, it is necessary to hermetically sneaking all the seams, after which there comes a turn of the catch. It is necessary to heat the rolls, to be founded and walls (on their lower edges), then the stripes must be glued.

- One of the last stages are grouting and grinding. It is thanks to them that you can get a perfectly smooth coating. After the screed hardens, you need to bring down the bumps, for this is used a metal screed. Then the surface must be pulled out with a special grinding machine.

Article on the topic: Choose an electric cultivator for giving: species and reviews

Semi-dry chatting of floors is very popular in many ways because it is durable and very strong. This contributes to the use of fibrovolock or reinforcing grid. Very robust design, short workflow time - all this features a semi-dry tie of the floor from other ways.