There are many different insulation. Foil insulating material reflects up to 97% of infrared radiation towards its receipt.

It is manufactured on the basis of polystyrene foam, foamed polyethylene, mineral and basalt wool. The correct installation will depend on its effectiveness.

In this article, we consider which side to lay the insulation with the foil to the floor, the types and characteristics of the materials, the rules for their laying.

What is a foil insulation

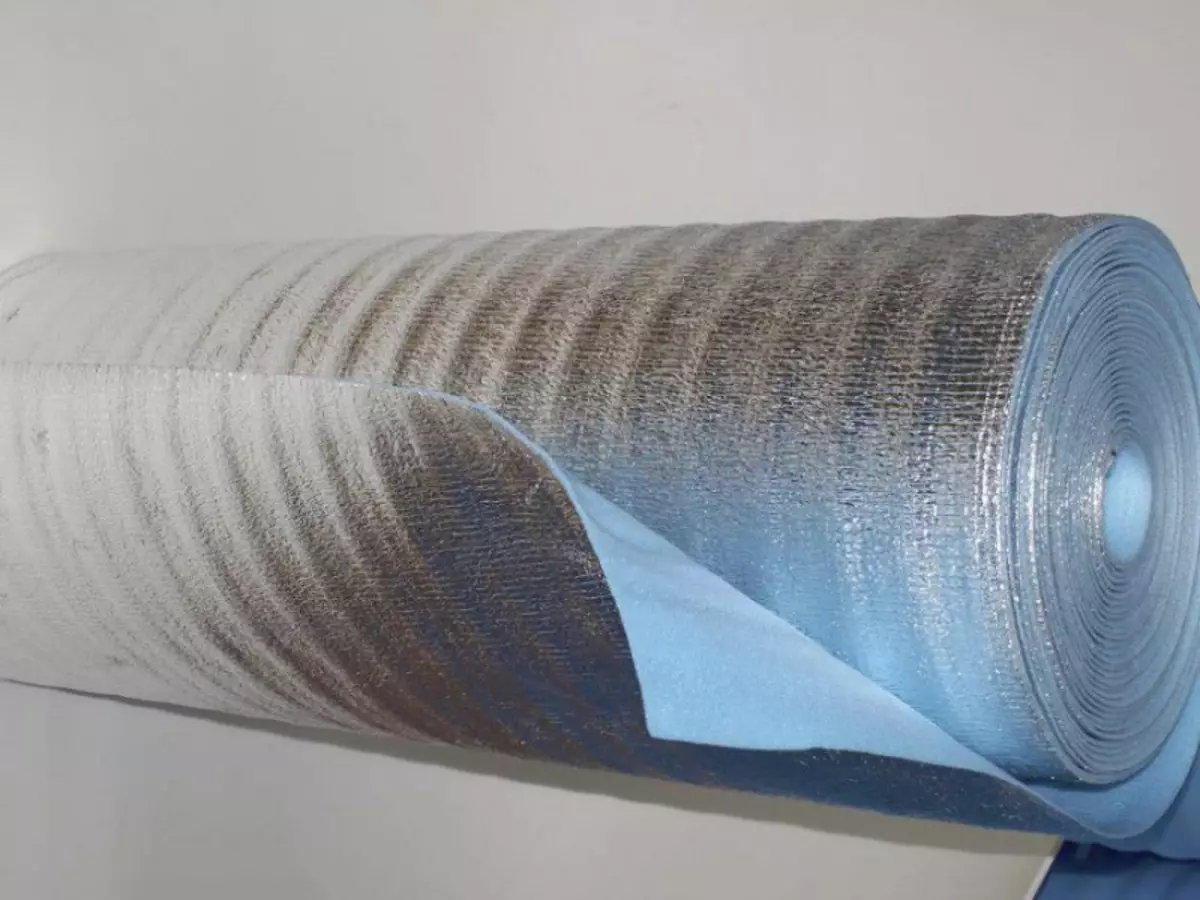

The reflective layer happens both from one and on both sides

This combined material, which consists of a layer of aluminum foil or metallized film connected to thermal insulation material. The reflecting layer may be one-sided or double-sided. It is distinguished by light and fast installation due to its elasticity. Thinner than other thermal insulation materials.

Aluminum coating has maximum heat reflection indicators, but is destroyed under the action of alkalis in concrete. Metallized coating is resistant to alkaline influences. Spraying practically does not fulfill its function.

In addition to the conservation of heat can be used as waterproofing, as it does not pass through itself moisture. The thinner the foil layer, the better hesitates the heat.

Types of insulation

There is a wide variety of foil insulation.

They differ in the materials used in the manufacture.

Characteristics of insulation with a layer of foil are described in the table:

| № | Foil Material | Characteristic |

|---|---|---|

| one | Polystyrene foam | Durable, reliable insulating material manufactured in the form of rigid plates. It is used for thermal insulation of water and electric heating floor. Operation in the temperature range from -180 to +180 degrees |

| 2. | Mineral wool | Environmentally friendly, fireproof material, 50-100 mm thick. It is manufactured in plates, rolls, cylinders. It is used in all spheres of insulation. |

| 3. | Polyethylene foamed | Produced in rolls, covered with aluminum foil. The material has a small thickness of 2 to 10 mm. The bottom layer may be on a self-adhesive basis. |

| four | Polyethylene foamed | Produced in rolls, covered with aluminum foil. The material has a small thickness of 2 to 10 mm. The bottom layer may be on a self-adhesive basis. |

When choosing, it is necessary to take into account the requirements for the room and its functional purpose. The upper layer must be covered with aluminum foil, and not by spraying.

Properties

Materials used in production are most often environmentally friendly, safe and environmentally friendly.

Article on the topic: High-quality wooden bunk bed do it yourself

Benefits:

- low weight;

- durability;

- stability resistance;

- protection against moisture penetration;

- high indicators of heat saving and sound insulation;

- resistance to temperature drops;

- ease of laying;

- High reflecting properties.

Such insulation can be used in any premises. In addition to the described qualities, it is capable of reflecting radiation radiation.

Methods of laying

Consider which side correctly put the insulation with the foil on the floor.

Heat-saving properties depend on how correctly the insulation is laid.

Foil reflects infrared radiation, therefore, the metallized layer must be laid so that it looks inside the room.

Warming of concrete floor

Put the loyalty of the foil down

Most often, the rolled material is fixed to a concrete base for a special adhesive made on the basis of rubber.

Installation sequence:

- We prepare the surface. Plate align so that there is no large difference in height. All slots and cracks close up with cement mortar.

- Especially the material on the floor with a foil layer up, cut off the desired length. Move the band, we apply glue to its place. Withstand a few minutes according to the glue instructions. We put and press the material well. Strips put close to each other.

- The joints are fixed by foil scotch, which is sold in construction stores.

For additional insulation of cold floors, you can put wooden lags, the space between which is filled with slab insulation. On top there is a germboard or sheet material (OSB, DVP, chipboard). Interesting comparison of foil materials See this video:

You can consolidate the material for double-sided tape, glued around the perimeter, or dowels.

Wood insulation

The most convenient to lay the material on the adhesive layerOn the wooden floor, the most convenient to lay a foil insulation having a lower self-adhesive layer.

If you bought the material without an adhesive basis, then it is necessary to fix it on the brackets with the help of a construction stapler or two-way tape.

Article on the topic: Installation and fastening the bath to the wall do it yourself

Stacking sequence:

- We remove the plinth, clean the garbage and dust with the help of a vacuum cleaner.

- If there are irregularities on the boards, we grind them with a special machine, if necessary, perform a cyclusion (removing the top layer of the board).

- All existing gaps close up with a putty on wood.

- Ground antiseptic composition.

- We measure the room, cut the roll, put up the foil. It is easily cut to the desired size with sharp sewing scissors.

- Unlock strips of online. Let's wait for the day so that the material is lying and dealt. If the thermal insulator has a self-adhesive base, gradually remove the protective film and tightly press to the surface. The next strip is stacked.

- The connectivity of the bands is fixed with foil scotch.

After the material is laid, you can lay the selected floor covering.

Folgized insulator under the warm floors

When laying an insulator under the warm floors, lay the foil material up so that it reflects heat into the room

The base under the warm floors should be smooth without drops of height and defects. All errors need to be eliminated.

Stages of laying thermal insulation with foil layer:

- Fungalized material is expanding with strips of jack, the connection location is sampled by special scotch.

- We mount the system of electrical or water warm floors on top.

- We lake the hydro and vaporizolation material. He will not give a concrete to the heating elements of the floor.

- Fill the screed with a thickness of 30-50 mm depending on the type of heating elements and the functional purpose of the room.

Warm floors can only be included after complete tie drying. It will take about a month.

Insulation under the floating screed

Having bought a two-layer material, you can not bother the question of which side to lay insulation

It is characterized by the fact that the plate is not fastened hard with a concrete tie, heat insulation is styled between them.

Installation sequence:

- We prepare the base, eliminate all defects.

- Plastering the bottom of the walls.

- We stick to the perimeter of the walls to the damper tape, its height should be in the thickness of the floor: from the plane to the flooring.

- Breasting the base in two layers. The subsequent layer is applied after drying the previous one.

- Thermal insulation foil plates are placed in foil up. We use a metallized coating, resistant to the effects of cement mortar. Plates are strictly in the horizontal plane, tight to each other. Uneven laying of insulating plates contributes to the formation of cracks in a concrete solution.

- Places connecting plates with scotch.

- Pour a concrete tie.

Article on the topic: How to plaster the ceiling with your own hands?

Lightweight and durable insulation with a foil layer is becoming increasingly popular among consumers and professional builders due to the high indicators for the maintenance of heat and ease of laying. For details on isolation, see this video:

We looked at how to properly lay foil material for high-quality floor insulation. The heat insulating material is always laid by the foil outside, if we are on the contrary, it will not keep the heat fully.