The adhesive for extruded polystyrene foam is selected for a specific type of work, taking into account the density of the material, which must be glued, its type and temperature and humidity regime during the production of work and during operation.

For external and internal works, different glue composition is used. In addition, the adhesive for expanded polystyrene should have a low thermal conductivity indicator so as not only to glue the polyurethane insulation, but also to improve the thermal insulation of the entire house.

Glue varieties

How to glue extruded polystyrene foam and how to choose the right glue to perform this simple operation, it can be understood by considering the species of adhesive compositions.

Please choose the required glue is not quite simple. All adhesive compositions consist of several components.

All types of glue are well glued panels.

Depending on this, they are divided into the following three main types:

- Bitumen-based glue;

- polymer cement glue;

- Polyurethane foam glue.

All these species have the properties necessary for gluing extruded polystyrene foam, and provide rapid grasp and reliable adhesion of the glued surfaces.

The composition of the glue for polystyrene foams should not include substances such as acetone and gasoline, because they are corrupted, making unsuitable for use, therefore, choosing glue, you need to make sure that it does not include aggressive solvents, essential oils or similar substances.

Bitumen

Bituminous glue do not need to heat before applying

Bituminous glue is a plaster-adhesive mixture, in which bitumen is used as a binder. It is perfectly combined with expanded polystyrene and fastens it well with a covered surface. Bituminous glue plastic and does not require preheating before use.

Due to the content in the composition of the bitumen glue, the surface, which was estrusted with its help extruded polystyrene foam, provided a thorough application of glue on the surface of the materials, has high waterproofing qualities.

Article on the topic: varieties of heated towel rails

This allows the use of this technology when insulation with polyurethane materials of foundations, first floor overlap, when furnaces on the soil and in other cases, when extruded polystyrene foam is used in structures subject to moisture.

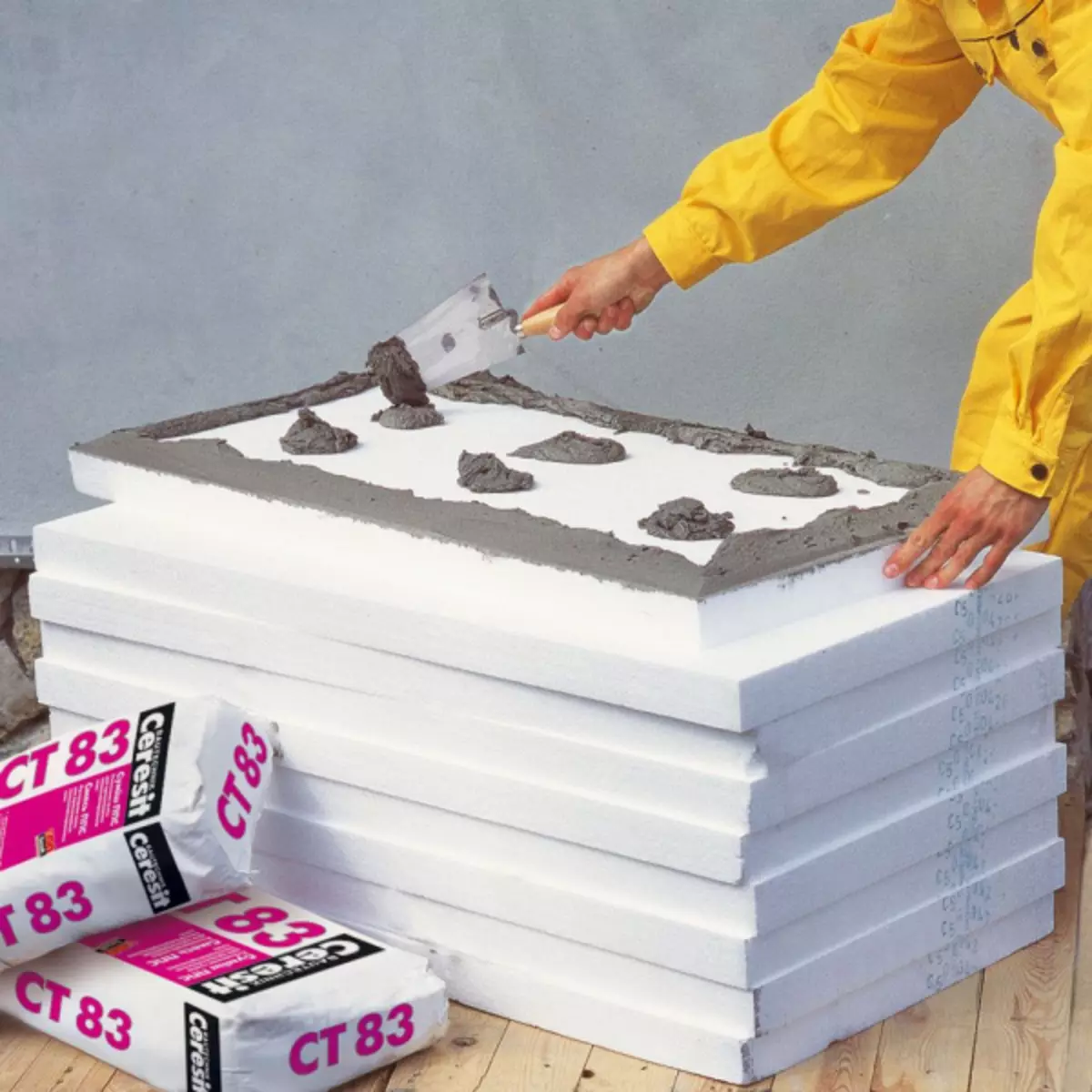

For high-quality adhesion of glued surfaces, it is necessary to pay attention to the application of the adhesive composition on the surface of the materials. It is distributed to a small uniform layer with a comb spatula.

This will make it possible not only to connect the materials used firmly, but also will ensure the creation of a high-quality waterproofing layer between them. After that, you need to create a certain pressure on the above-mentioned materials for half an hour. This can be performed using spacers, clamps or using other available methods.

Preparation of glue on a bitumen basis does not require much effort and is carried out in minutes with the help of an electrician with a nozzle in the amount necessary for high-quality work.

Polymer cement glue

This type of glue is used in the insulation of concrete surfaces.

This adhesive is designed to be covered with surfaces made of concrete, brick, aerated concrete, hypina and wood. It can be used when performing internal and facade works. These mixtures consist of portland cement and various components that provide plasticity and other properties for adhesive compositions.

Before applying, deep high-quality impregnation of surfaces of glued materials is required. After soaring, polymer cement adhesives form a solid durable crust.

Polymer cement glue is used if necessary reinforcement and subsequent finishes of the treated surface.

Due to the high adhesive properties, it is widely used for stickers of polystyrene foam on ceiling surfaces, resulting in high-quality and reliable ceiling designs.

Polyurethane foam glue

This adhesive is grabbed for 10 minutes.

Polyurethane foam is a very high quality and reliable means for gluing extruded polystyrene foam to various surfaces. Setting it after applying to the surface of the material is no more than 10 minutes.

Article on the topic: Nights Plumbing - 2019: Mixers, sinks and toilets of amazing design

To stick a polystyrene foam on the surface of 10 m2, a single foam can, whereas the consumption of the adhesive mixture on this surface ranges from 20 to 25 kg, depending on the type of mixture and the quality of the glued surfaces. For details on how and what to glue the foam, see this video:

The use of polyurethane foam glue has the following positive points:

- economical spending;

- when used does not emit harmful substances;

- dries after 2-3 hours;

- does not require additional surface preparation;

Polyurethane foam composition has a high price

With the help of a foam, the surface of the surface of the surfaces by extruded expanded polystyrene is performed quickly and easily. The disadvantage of this method is the high cost of polyurethane foam glue.

The regulatory consumption and capacity of packaging and containers in which glue for foam and expanded polystyrene can be chosen according to the data specified in the table:

| The name of glue | Capacity | Consumption per 1m2. |

|---|---|---|

| Bituminous glue | From 1 to 50 liters | From 1 to 1.5 kg |

| Polymer cement | Bag 20-25 kg | From 4 to 5 kg |

| Glue-foam | Cylinder 75-100 ml | 100 ml |

The use of listed types of adhesive compounds and compliance with the technology and sequence of the work steps will make it possible to perform with polystyrene foam of the treated surfaces easily, quickly and efficiently.