The process of organizing insulation today is paying much attention, since it depends on it, how energy-intensive will be a residential or domestic room.

Indeed, now pay great attention to the preservation of heat in the room, since the heating resources (wood, coal, gas and electricity) are expensive, so your home or apartment is taken to warm and create maximum efficiency of work with heating elements. Frequently used polystyrene and mineral wool insulation, including extruded polystyrene foam for a warm floor.

Polystyrene foam for a warm floor of its characteristics and types

The warm floor is a modern type of heating system, which many owners dream and seek to introduce in their residential premises. This heating system can be both basic and additional to centralized heating.

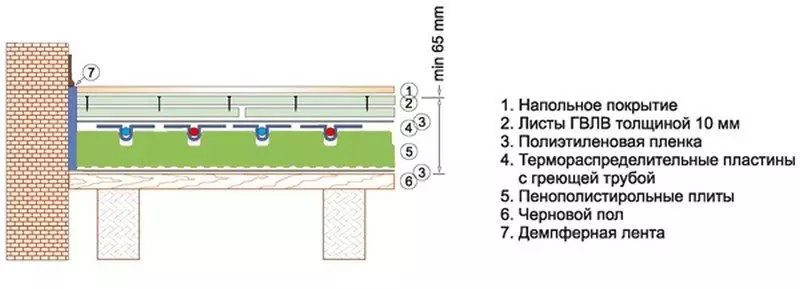

The recommended height of the "cake" of water underground should be 7-9 cm, and electrical 6-8 cm.

Warm floors do not occupy any place, as they are located under the finish cover, but there are a lot of difficulty in installing them, as it is necessary to pour an additional tie, which bears additional costs, reduces the height of the room and performs additional load on the overlap.

People are not always taken to organize this heating system due to the shortcomings of the shortcomings, but in recent years, many builders have been solved this problem, due to the emergence of a special insulation - polystyrene polystyrene in the market.

This material has a small weight, a small thickness (2-5 cm), as well as easy and quickly mounted.

Specifications of polystyrene foam

Material will withstand temperatures up to + 80 degrees

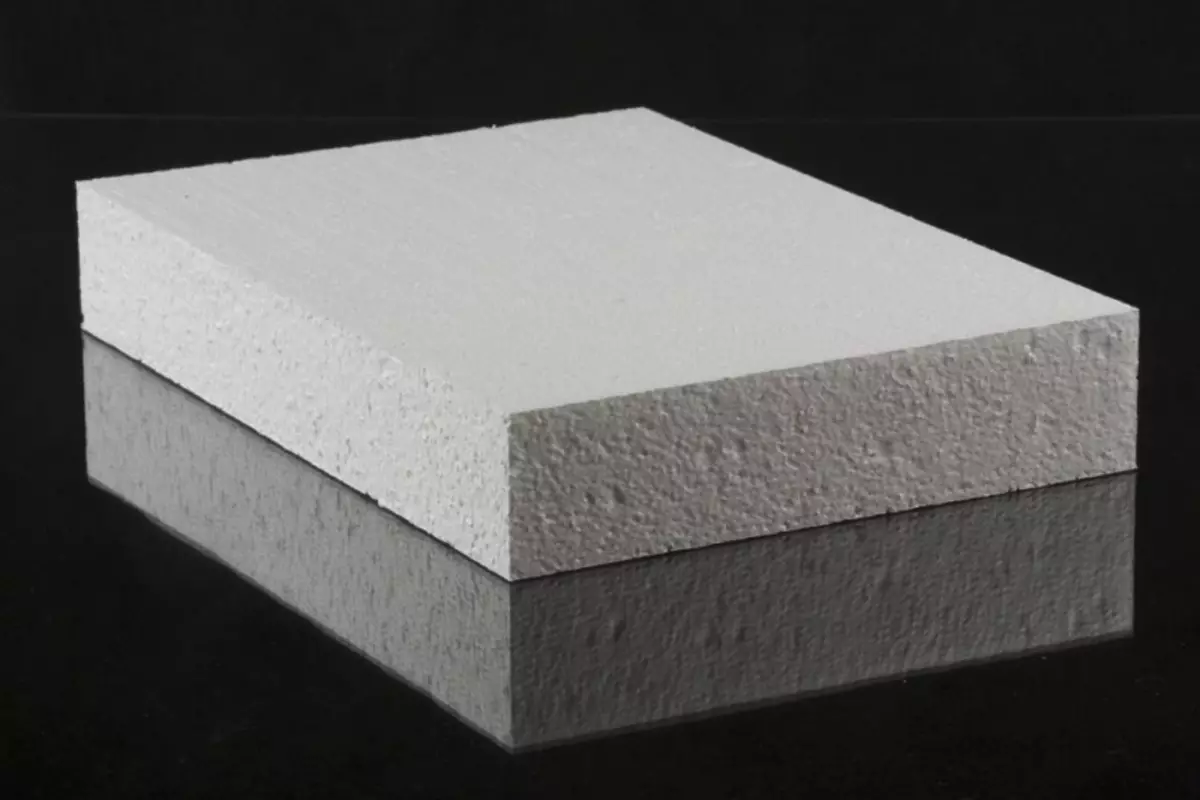

The polystyrene foam is great for the creation of the initial layer of the "cake" of a warm floor, since it has a smooth surface that is perfectly combined with the draft overlap. It has a slightly noticeable porous structure. Like any other building material, expanded polystyrene has its own specific characteristics:

- It can be applied and mounted with absolutely any temperature indicators: from -65 to + 80 ° C.

- The bubble structure of the material is capable of providing excellent thermal insulation properties, having a thermal conductivity of 0.036 - 0.044 W / m2.

- The consequence of the porous air-filled structure is the low weight of the plate.

- The material is capable of performing 2 function - waterproofing, since it absolutely does not absorb moisture.

- Polystyrene products have good noise protection. Plate layer 2 cm is able to reduce the noise level by 20 dB.

- Polystyrene has self-effect properties and has a rather low flammability, but in the process of tensioning the material allocates a number of harmful substances threatening human health.

It should be known that the polystyrene foam is a direct relative of the foam, but has a greater density (3-4 times) and a smallest bubble structure, which indicates a great value.

It should be remembered that the thermal conductivity of 10 cm of polystyrene foaming corresponds to 1 m of brick masonry and 37.5 cm of wood.

Article on the topic: Hovering curtains on hooks: The main stages of work

Varieties of expanded polystyrene foam

Disposable fragile and breaking panels

Many polystyrene manufacturers use different production technologies, which leads to the creation of material of different types. To date, there are the following types:

- Unpressed polystyrene foam (EPS, PSB-C). The process of drying granules is produced twice. Once before foaming, and 2 times after this event. Then the material heats up and bottled in forms. This is the most common version of the production process of polystyrene foam, it has the smallest costs, but is the most fragile material.

- Extruded (EPS, XPS). This production of the material is characterized by a production process passing under high pressure in a certain container, into which a special reagent is introduced for foaming. After that, the whole mass is squeezed through the extruder already into the shape of the plate and dried.

- Pressing polystyrene (PS-1, PS-4) has the same thermal conductivity, as well as extruded, but production processes are different.

- The autoclave production method is no different from the extrusion, only when foaming the granules, manufacturers apply an autoclave. Such material is not used for thermal insulation.

It should be known that in the production process in the polystyrene foaming, a special additive is added, which has an antipiren substance, which adds a construction material of fire safety. The use of such an additive is regulated by GOST - 15588-86.

How to make a choice of material yourself?

Each host seeks to ensure that the best material is used on its construction site, it also applies to polystyrene foam. Choosing material for a warm floor, you should pay attention to:- Product color. It should be bright over the entire surface.

- The smell must be absent. The sharp smell from the material corresponds to the low quality and incorrect production process.

- The edges of the product must have a density and not crumble.

- Smooth surface without any dents and bulges.

- Granules of the same size.

Choosing the material, you can independently carry out a small experiment: you need to break one plate and analyze the place of the split.

If the stove cracked not clearly at the place of fault, and the wave (the granules remained integer), it means that the firing process was incorrect, and this material should not be purchased. About choosing a heater for a warm floor, see this video:

Article on the topic: What to do if the shower is flowing

Features of the installation of polystyrene foam under the warm floor

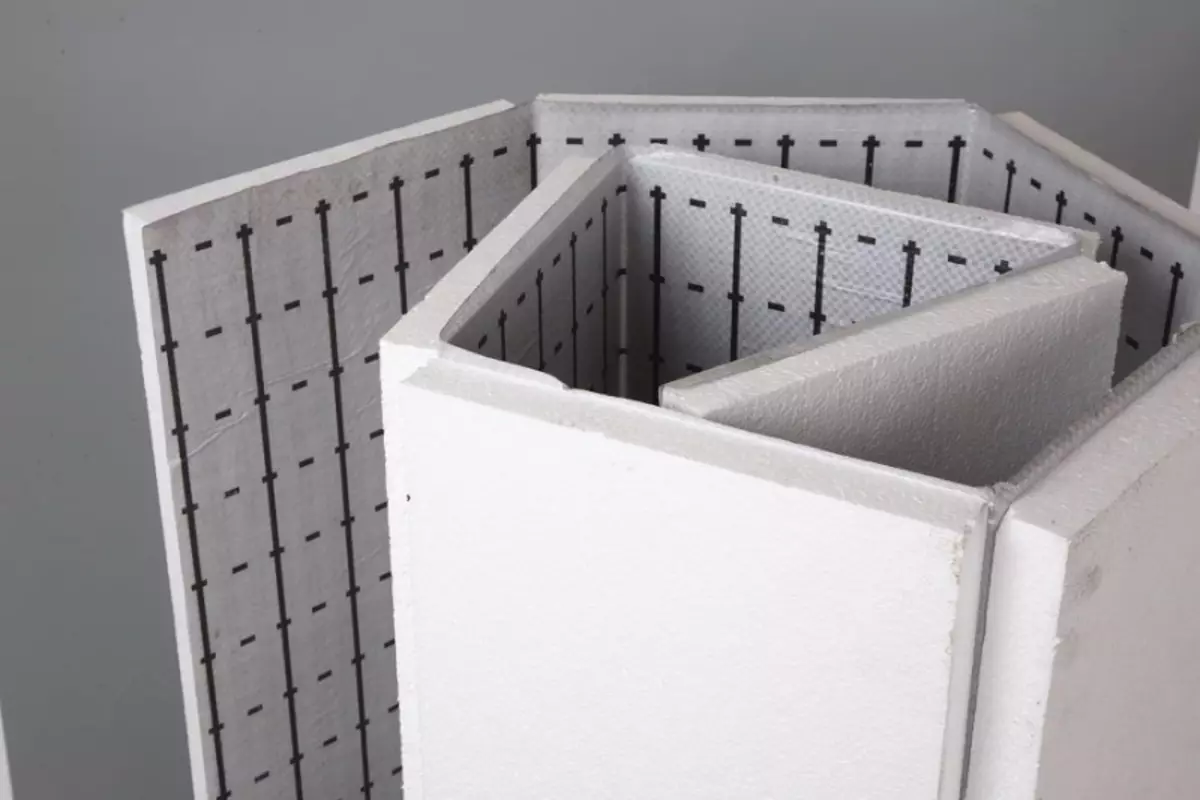

Insulation plates must be tightly adjacent to each other

The warm floor is not necessary to organize on a concrete black screed. The support structure can be a wooden flooring, the main thing is that the plates of polystyrene foam are laid tight towards each other.

Before retaining the insulation slab, it is necessary to clean the coating from the garbage and eliminate all the irregularities.

It may take to repair a rough screed with a special mixture, closeing all cracks and damage.

When you were convinced that the surface is smooth and clean, you can start the installation of polystyrene foam plates. At the same time, each unit of the product should not be written and move. All thermal insulation flooring should fit tightly to the walls.

Many specialists strongly recommend applying thermoaccuistic film by placing it under the insulation and thereby enhancing sound protection and thermal insulation.

A number of polystyrene manufacturers create plates with grooves and spikes. When installing such a insulation, you need to pay attention to the fact that the docking elements are not damaged.

Special plates for warm sex have not only connecting grooves, but also limiters for laying pipes or electrical cable.

Usually, pairs of limiters are located at a distance of 3-8 cm from each other, thereby allowing you to arbitrarily choose the distance between the heating elements.

After laying the cable or pipes between the limiters, a trial launch should be made and cover the heating elements by waterproofing film (with water warm floor).

Easy coating, such as parquet or laminate, can be cut right on top of polystyrene foam, and rolled materials (linoleum, carpet) and tiles should be placed on the leafy materials of Phaneur or OSB-slab, which is steel to the insulation.

In rooms with high humidity levels, self-leveling mixtures are used, which are poured on the insulation, in one level with intervals for laying pipes.

Article on the topic: 43 Original Council! Small household tricks that everyone should know (photo, selection)

One example of the flooring can be seen from the diagram.

From this article, each owner will be able to emphasize information on the choice of polystyrene foam for a warm floor. It is worth deciding with its product option, given all the shortcomings and advantages. The choice of material should be performed only on your own.