Laminate - floor material, which externally might mimic natural wood and even tiles. It is distinguished not only by attractiveness, but also durability, durability, good indicators of thermal insulation. In order for the laminate to fully fulfill its functions, it is necessary to lay a special substrate before it laying onto it. Its main purpose is to protect the laminate boards from rapid wear. How to sharpen a substrate for laminate if there is no experience with such material? At first it will have to choose correctly, and it will not be superfluous to explore the installation instructions.

Comparative characteristics of substrates for laminate.

Purpose of the substrate and its types

The substrate has such functions:

- Soundproofing. The laminate itself is well protected from noise, but during walking it is very knocking on the basis of the floor. The substrate allows this knock not only to muffle, but also to do almost indistinguishable, that is, it will not be heard from the neighboring rooms. There are a number of substrates that even strong blows that occur when falling on the floor of certain items.

- The creak when walking no longer bothers, as the substrate blocks the contact of the floor and the laminate board, the pressing of its locks. Along with this, the service life increases.

- Excellent thermal insulation. Even in the cold season, such a floor will be warm and cozy.

- The substrate allows you to align small defects of the base base.

Laminate board structure.

What kind of substrate to purchase, what are they made from? Manufacturers offer the following options:

- cork natural and combined;

- polyethylene;

- Special.

Polyeneetylene or cork?

The easiest option is polyethylene materials that are distinguished by low cost. Such material has its advantages:

- The product is not subject to rotting, insect attacks.

- The characteristics of thermal conductivity are excellent, the substrate well protects the floor from heat loss, makes the coating more comfortable.

- The material density is sufficient so that you can lay a 2 mm thick substrate under the laminate.

Article on the topic: Bed Children's Children's hands on the principle of groove spike

But there are a number of flaws that often reduce all the advantages. This type of substrates is distinguished by the short and shrinkage. The canvas remembered that increases the risk of breaks, damage to the laminate board. When walking, screens and stuffs appear, furniture and equipment begin to urge the boards, over time they are easily breaking and covered with cracks.

Scheme of cork substrate under the laminate.

The second option is cork plates. Such a material is characterized by a high cost, but this is quite justified by all properties of the coating. The plug is dense and durable, is considered an excellent heat insulator, it is not affected by moisture, temperature drops. Cork slabs allow you to properly distribute the load, so the wear of the laminate board will be minimal. Installation of this type of coating is simple. The plates simply fit on the floor surface are not glued. The thickness of them may be small, but it is impossible to use the material in 2 layers. Of the minuses it is necessary to mark a high price, which is often an obstacle to the purchase of plates.

Special types of substrates are designed for certain operating conditions. For example, increased noise insulation. Some varieties of products provide reliable moisture protection, can be used for corridors, kitchens. Choosing one or another option, it is necessary to revise everything for and against.

Technology of work

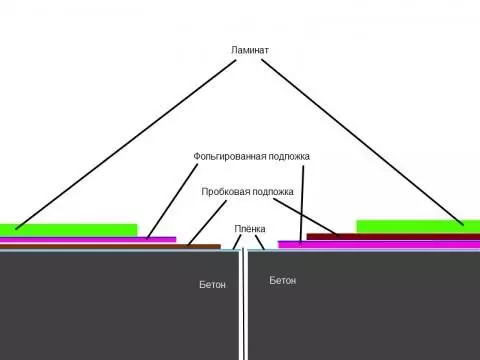

Laminate laying scheme for a substrate.

To drain the substrate under the laminate, you need to prepare materials and tools:

- The substrate itself is a selected type (can be supplied in rolls or in tiles, such as cork);

- a hammer;

- spacer wedges;

- scissors or knife for cutting material;

- Polyethylene film - it is necessary when the substrate is laid on a concrete base;

- ruler, pencil;

- Bar;

- Construction Scotch.

When you select tools, you must focus on what kind of substrate type is used. How to sharpen a substrate for laminate in a house or apartment? The session will be as follows:

- Preparation of the base, if necessary, it is repaired, alignment.

- Laying waterproofing and thermal insulation on a concrete base.

- Installation of the substrate of the selected type.

- Laying a laminate board.

Article on the topic: Plastic bathroom panels: photo Repair options

The first stage is usually the most difficult, since for alignment is required in some cases, the fill with the cement mixture is required. You can do this by inviting specialists.

If the floor is quite smooth, then this stage is to clean the surface from the traces of the old coating, dust, garbage, and other things.

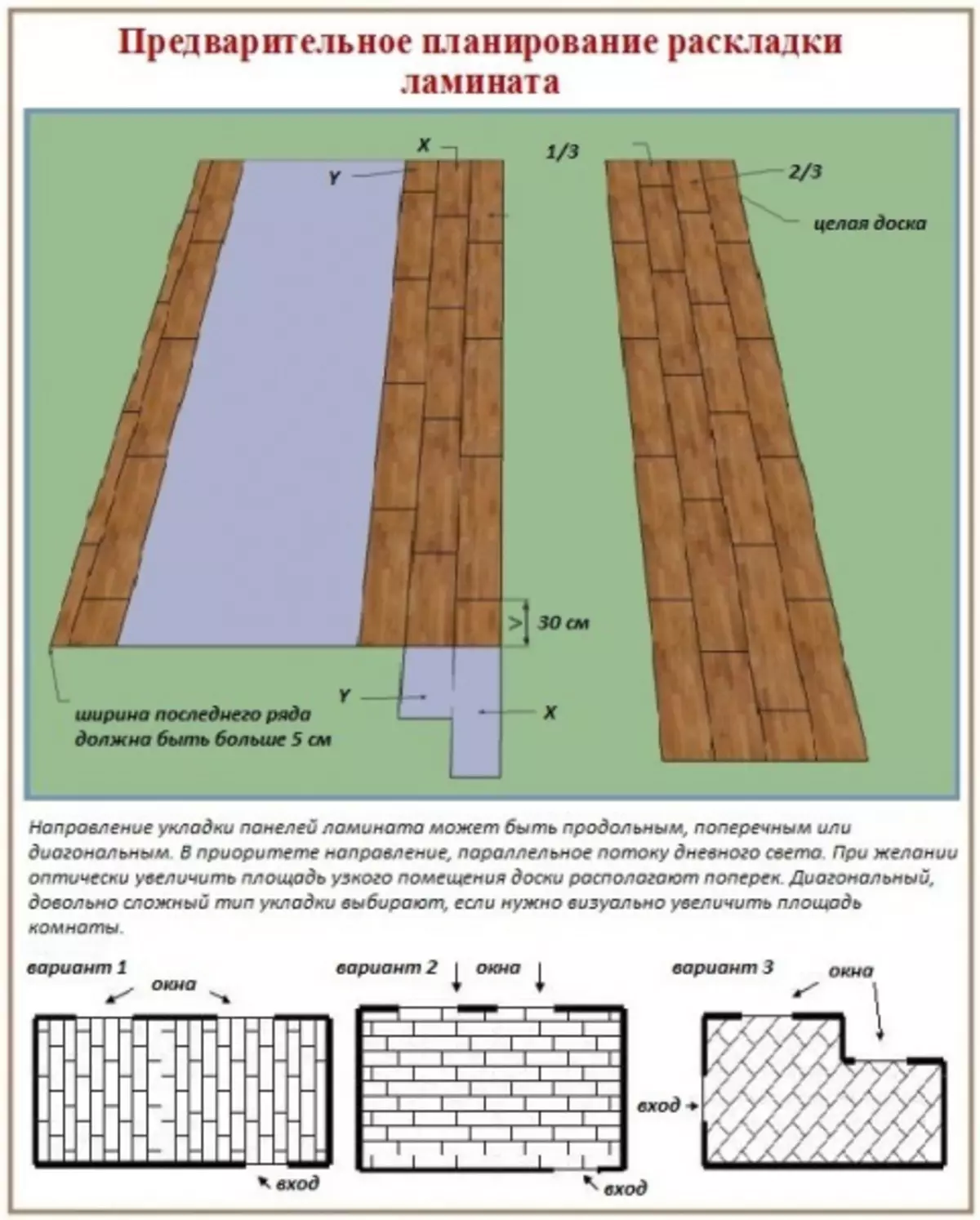

Options for laying laminate panels.

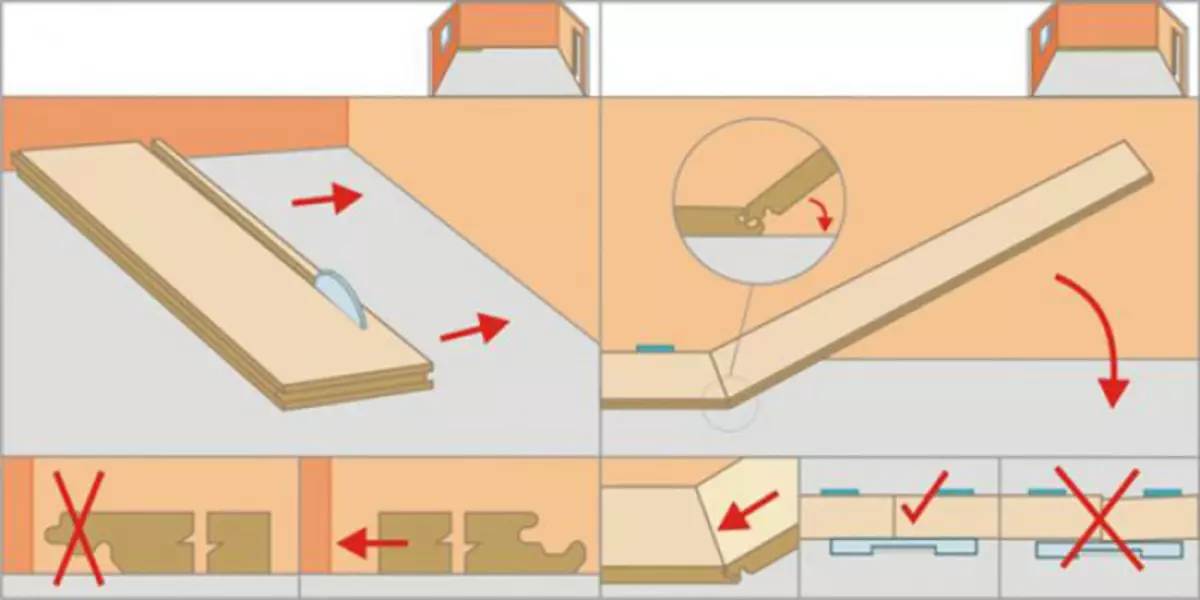

The technology of flooring is extremely simple:

- First examines the surface of the base floor. If there is a need, then cracks and other defects are closed. A layer of waterproofing from a polyethylene film is placed on the concrete base. The canvas stel a mustache, after which all the joints are sicked with scotch. On the surface of the walls, the film should go about 10-15 cm, after performing all the works, its excess is simply cut.

- Next, laying the substrate is performed, it is best to use a material with a thickness of 2-3 mm, but not more than 4 mm. You can not lease the substrate in 2 layers.

- If the roll material is used, the substrate simply rolls out. To drain under the laminate, this material is necessary in the direction in which the laminate board will be mounted. During the stacking, there should be no breaks and other defects, the bands are fixed with adhesive tape. To the floor and walls, the substrate is not fixed in any way.

- If a substrate from the plates is used, then it should be flat-up. Foil foil material should also look up. When fixing the plates are not glued to the floor, walls. Shakes are fixed with adhesive tape.

Useful advice

So that the provider be laid correctly and efficiently, it is necessary to follow several ordinary tips:

- Stop the substrate must be perpendicular to the walls.

- During the styling, it is necessary to ensure that there are no gaps and cracks. The material should be laid from one wall to another, if necessary, the joints are sampled by scotch. It is important to accurately comply with the laying technology.

- It is not recommended to take too thick substrate, as it will be the reason that the floor will spring. When installing furniture and household appliances on such a laminate, the board will be pushed, cracks will appear. In addition, this floor is inconvenient to walk.

- It is necessary to choose the substrate in such a way that it differ not only by all the necessary qualities, but also durability. Today, manufacturers offer a range of coatings at a low price, but this leads to the fact that the material is quickly pushing, ceases to perform their protective functions, the laminate itself is rapidly flashes.

Article on the topic: Lilac wallpapers: for walls in the interior, photo, colors, with what are combined, tones, pale lilac with flowers, what color sofa is suitable, video

Today you can purchase various types of substrate under the laminate, which one to choose - to solve only you.