When it comes to GWL, we can safely say that this one and the most popular and largely sought-after materials that are used in decoration and construction. Having a huge number of advantages, it becomes an integral part in many repairs. Hypus fiber sheets are produced by combining gypsum and cellulose fibers, which in turn are obtained from recycled waste paper. Today I will tell you what GVL is, what is his size and where it is possible to use this material.

Finishing GVL

Features and specifications

Compound of sheets of GVL

Due to various additives and high-quality plates, a mixture is obtained, which is turned into a dry-fiber leaf using a press under pressure. The material is obtained very durable, and the designs of it have a high bearing capacity. GVL from drywall is distinguished by the composition. Despite the fact that GVL is an analogue of drywall, it is much better and its operational characteristics exceed the opponent several times. Finishing with such plates becomes more durable and reliable. Due to such advantages, dry-fiber sheets can be used when it is necessary to ensure the rigidity and strength of the partition. The homogeneity of the material speaks of its wear resistance and excellent stability before mechanical damage.

GWL finish with their own hands

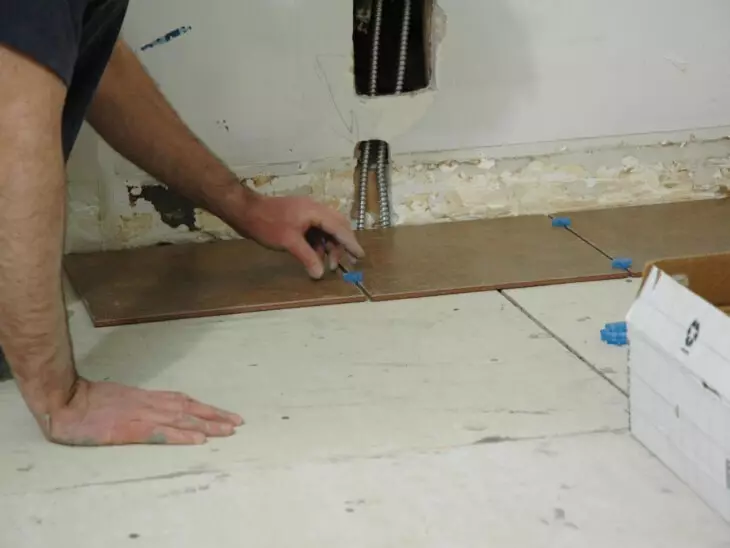

GVL can be used as a substrate for floor overlap. Thus, you can carry out installation without a large amount of dirt and align the floor at the same time. Plates can be cut under the desired size, leaving the minimum of waste, but if you choose them correctly, you can speed up the installation, and reduce costs. Although this material is predominantly better than plasterboard, but still has some minuses:

- As a material with increased rigidity, it is difficult to obtain the design of curved forms from it. The bending of the plates go bad and therefore for figure structures it is necessary to use precisely plasterboard

- The price of GVL is an order of magnitude higher, so for some such expenses will be undesirable. However, for the sake of improved characteristics that the material extended for a long time, you can spend a little

Article on the topic: Original curtains in the kitchen

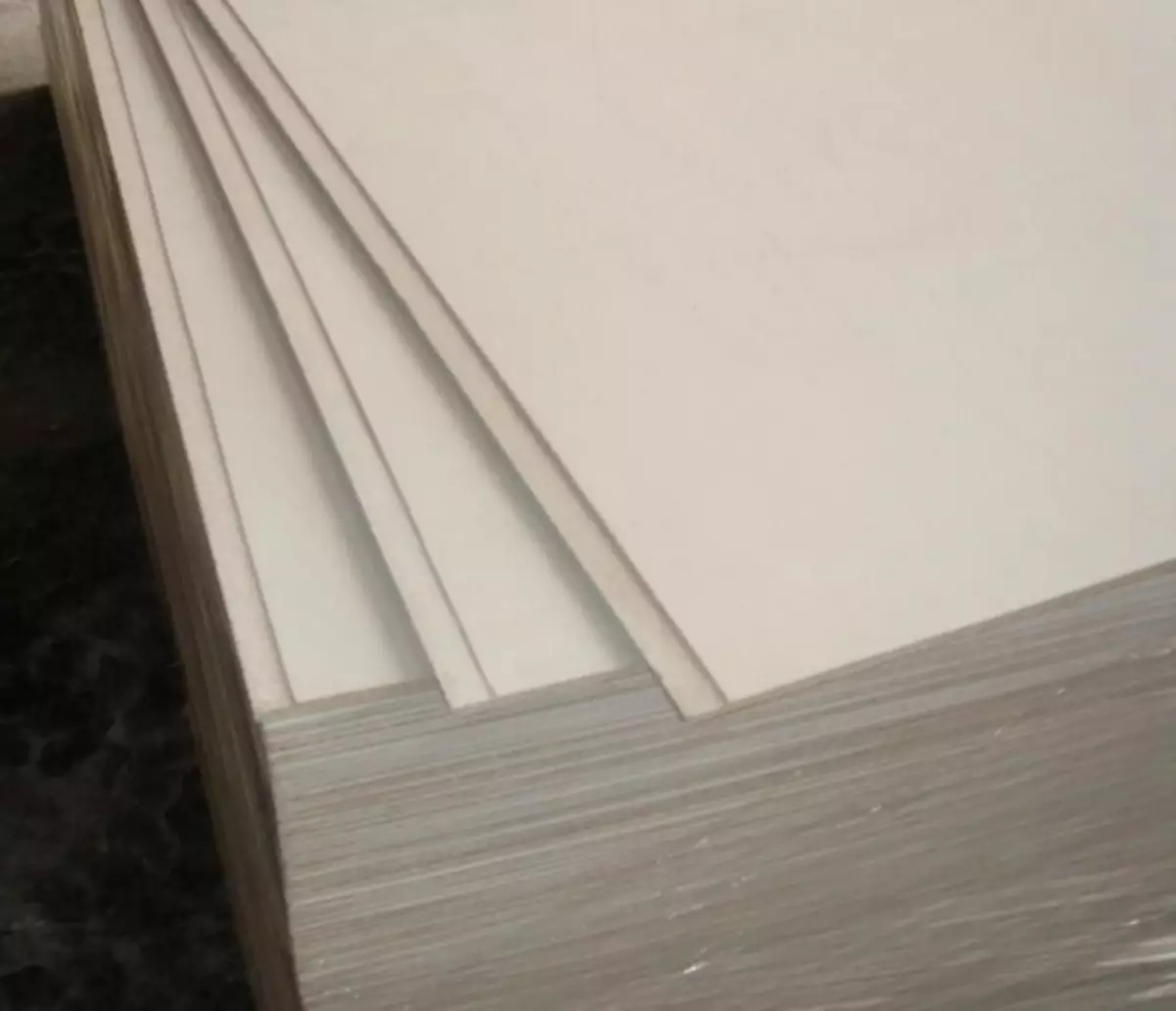

The convenience of installing a sheet of GVL, as well as finishing with it is quite simple. In addition, the plates have standard sizes, regardless of the manufacturer, which manufactures the material.

GVL

Table 1

| Gabarits. | Dimensions in millimeters |

| Length | 1500, 2000, 2500, 2700, 3000 |

| Width | 500, 1000, 1200 |

| Thickness | 10, 12.5, 15, 18, 20 |

GWL Sheets

When the installation work is carried out in a private house, the sheets of GVL 1500 * 1200 mm are used, the thickness of which is 10 and 12.5 mm. Such dimensions of the material allow work independently and not only to align the walls, but also to create partitions and even bearing walls. Installation of larger sheets, the thickness of which is 18 and 20 mm, and the length and width - from 2500 * 1200 mm, produce qualified specialists. With the help of such plates, walls and partitions of large rooms and industrial structures are separated.

In addition to the usual GVL sheets, there are moisture-resistant, which is called GVLV. The table below you can see the important characteristics of the plates data.

table 2

| Characteristic name | Value | unit of measurement |

| Humidity | Less than 1.0 | % |

| Density | No more than 1200. | Kg / m3. |

| Hardness | Over 22. | MPa |

| Bending strength | More than 5.5 | MPa |

| Thermal conductivity | 0.22-0.35 | W / m * with |

Installation of GBL sheets

In what cases is possible use of GVL:

- Mounting of the gypsum fiber occurs during repair and construction work in apartments and houses, where normal or low humidity level

- It is possible to use GBL even in basement or attic rooms, provided good ventilation

- If there is a desire to apply GBL for walls in the kitchen or bathroom, where the humidity is increased, then use moisture-resistant materials, called GVVV

- In addition to the construction of the partition and the sheat of the walls in the house, it is possible to cover even unheated structures. Such can perform garages, sheds and other economic structures. Material is frost-resistant

- The use of GWL provides fire protection for buildings erected by wood.

In addition, the installation does not require the use of adhesive solutions

Article on the topic: Black and White Curtains in the Interior of the Apartments

Partition with Hydrophole Sheets

GWL floor team

In addition to all the advantages in the characteristics and sizes of the GWL, with their help, it is possible not only to finish the walls, but to build partitions with your own hands. Due to its independent execution, the costs of repair and construction work can be significantly reduced. The construction of the frame partition obliges the construction of the design of steel profiles, which are in the future are trimmed with GBL sheets into one or more layers. To achieve good sound insulation indicators, the mineral wool is laid between the plates of the gypsumless material.

Unlike hard-refrigerated partitions, a skeleton method is rapid and easy, moreover, has good sound insulation indicators. If the installation of the partition occurs after construction of the box, it is better to use moisture-resistant GVL, especially if the room has not yet been dry. Unlike a partition from brick masonry, various communications can be laid into the emptiness between the GVL sheets. If the pipes are passed through them, do not forget about the sound insulation layer, which will close the pipes. Do not forget about the possibility of choosing the necessary dimensions, thanks to which the installation of the plates will be more convenient. Standard sheets of sheets can be seen in Table 1.

Structure of walls of trimmed GVL slabs:

- For starters, the framework is erected. This uses metal galvanized profiles. The frame itself consists of rack and guide profiles.

- After that, lay a sound insulation layer. An excellent option will be the use of mineral wool or polystyrene foam

- Then the frame is trimmed with the help of self-tapping screws and sheets of GVL

- Fill out the seams and joints - use a quick-hardening putty for seams along with the reinforcing ribbon

- Align the surface of the wall with putty. The thin layer is applied to the wall and allows you to create a flat plane. You can use gypsum putty, and apply it with a spatula

- If in the future the walls will be stained, then we use the finish putty, which is grated or sandpaper after drying

- To complete the process of finishing the walls, you can use wallpaper, decorative panels or decorative plaster. Finishing the finish putty in this case is not needed

Important! Self-tapping screws are screwed into the slab to a depth of 0.5-1 mm. Do not allow cardboard coating breakthrough, the screws should not perform above the surface of the plates.

With the help of spacing, self-tapping screws are hidden and become invisible.

RESULTS

GVL sheet floor team

Article on the topic: how to make a laundry dryer from plastic pipes

Such a wonderful material, as a dry-fiber leaf, is extensively used in construction and finishing processes. Despite its value, which is higher than conventional plasterboard sheets, it also has more characteristic advantages. The service life of GVL is much longer than its predecessor, and the presence of moisture-resistant plates allows installation of it even in rooms with high humidity.