After installing plastic windows, the window opening looks far from the best: sticking foam, pieces of plaster, visible places of walls. All this "beauty" is closed in various ways, the most practical, fast and inexpensive of which is plastic slopes. Make them better from sandwich panels (two layers of plastic, between which foamed polypropylene). They are dense, durable, make from a good material.

The main methods of installing plastic slopes are two: with a starting profile and without it. Both are given with step-by-step instructions and photos. How to fix the slopes on plastic windows decide for yourself. Both ways give good results.

Photo report 1: Installing slopes from sandwich panels without starting profiles

This method is suitable when the window is set so that the distance from the window frame to the wall of the opening is too small. In this case, installation with a starting profile (see below) or is very complex, or - usually from the loop side - it is generally impossible.

After installing the plastic window, such a picture was observed.

Picture After installing PVC windows

The device of slopes of plastic windows begin with the preparation of the opening: the remains of the foam cut off the stationery knife. It is cut, it is easy only do not overdo it, cut off the thief, and do not cut - foam and keeps, and warms the frame. Also, pieces of plaster, which interfere and protruding are removed. If they hold well, and do not protrude for the plane of the future slop, you can leave them - less foam will slide.

Then it is nail around the perimeter of the window (we put on a dowel if the wall is concrete) thin rail - 10 * 40 mm - a wide side of the slope.

Nailed around the perimeter of the rail

Usually do not flatter it, they are nailed as it is, but if you want, you can put it smoothly, laying the pieces of plywood in the right places, and the like.

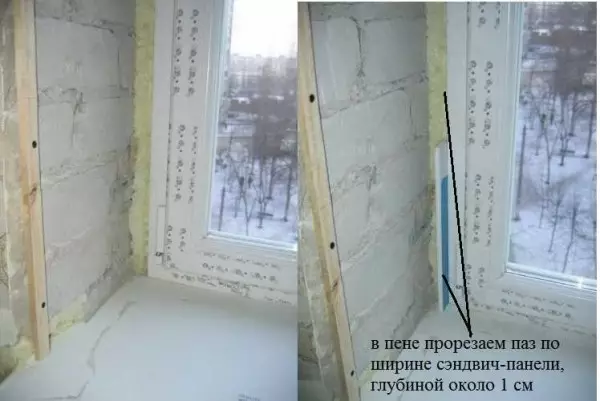

Paz under plastic sandwich panel

Next, along the perimeter, the foam frame is cutting up so that the sandwich panel is stood there. Should it go about 1 cm. The foam cut off gently so that the residues on the frame there were, but also without damaging plastic.

Now you need to properly cut off the plastic panels. You can make a standard: with measurements, you can make a stencil. With stencil, it seems easier. Take a sheet of paper, more than your window (I had old wallpaper). Apply to the slope, crimp, bending superfluous. At the curved lines cut off, try on, adjust the need.

It is more convenient to start with the right part of the opening. By making a paper stencil, outlined it on plastic. Given that about 1 cm leaves the foam groove, along the edge, which will be inserted there by adding this centimeter. With a slight margin, cut out - cut off easier than to lure.

We cut with a knife with a web for metal, try, correct to get the plastic exactly, without flexing. Less so that the panel is to be closed with plaster. The edge is almost smooth, where necessary, we work around the file.

Inserted top of the plot of plastic

Removing the exemplary and fitted strip, along the outer edge, which will be nailed to the bar, chose the holes over the thickness of the carnations, retreating about 0.5 cm from the edge. So easier to fix it and do not damage the plastic.

Article on the topic: Designs of furnaces for the Russian bath

Again, put in place, we take a cylinder with the mounting foam and short "pshiks" fill the lumen of foam. We try to get as deep as possible, but we do not leave much: he swallowed it can conquer plastic.

Fill around like that

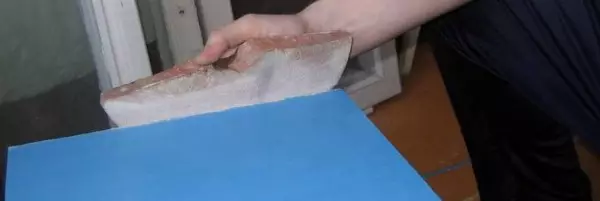

There are several moments on working with mounting foam. If the plastic is smooth, the foam has a not very good clutch with it. To improve it or process the surface, which is facing the wall, eye, or / and to be primed to improve the clutch. The second nuance: for normal polymerization of foam you need moisture. Therefore, before installing the plastic, the slopes are sprayed with water from the spray. Naturally, dust on the wall should not be - it is sweeping with a brush or removed with a vacuum cleaner. If the plaster or mortar is loose, pre-work is treated with penetrating primer, which will connect particles of concrete among themselves.

After the panel, putting a foam, carnations insert into the holes and secure the outer edge to the bar. The inner holds, resting in the frame of the window.

Fastened top plastic panel on window slope

According to the same technology, we cut a paper pattern, try, we carry on the plastic - cut out the plastic sidewall. Here you have to be particularly accurate, so that there is a minimum between the panel of the slope and the windowsill (upper slope). To do this, the edge will have to treat emery paper. To make the edge smooth it was easier, it is more convenient to process it with a sandpaper attached to a smooth bar, a file or a grinding bar (half a circle, as in the photo).

Plastic Panel Edge Treatment

We caught up to the ideal (as far as possible) coincidence at the top and bottom, install in place, driving one edge into the groove near the window. When the result is satisfied, level the outer vertical edge in one level with the plaster wall. You can do this by a stationery knife on the spot, and you can act on the panel (a pencil, a thin marker, scratch something sharp) and then modest than convenient.

After removing, on the outer edge, too, drill holes under the carnations. We set the panel to place, we take foam, and from the bottom-up fill the gap. Too much foam and here - it is not good, since plastic can bump. Therefore, fill in short portions, trying to fill as deep as possible.

On vertical parts of slopes, you can do differently: on the finished installation panel on the far edge, which starts under the frame, apply foam to installation. The strip is made solid or impose a small snake. Just to do it not from the very edge, but stepping a bit. Then the plastic part is set in the carved groove, exhibit as needed, fill the rest of the clearance (do not forget to moisten the wall before installing). Filling, pressed, align, fasten with cloves in the bar.

The upper and lower joints are fixed with painting tape to the polymerization of foam.

So that in the process of polymerization of the foam did not move the edges of the slope, at the top and at the bottom of the joint are sampled by painting tape. No matter how trying to customize exactly plastic, crack, although small, remain. They can be smeared with acrylic. It is sold in the tubes of the type of mounting foam, put in the same mounting gun.

Article on the topic: Features of the installation of a water "heated towel rail-ladder"

Squeeze the strip in the gap, wear, align, excessive clean with a damp soft cloth or sponge. It is necessary to do this operation in small areas and wipe carefully. While acrylic is not frozen, it is cleaned well. Then - with pretty labor. It is more convenient to start the sealing of the slits - immediately - the horizontal panel of the slope, then the joints, then move down first on one side, then on the other. The latter shots with a window sill.

After drying, 12-24 hours depending on the sealant (written on the tube) acrylic can drag into the seam - this is if the gaps turned out to be large. All these places go through the second time on the same technique. After the second layer is dry, if there is roughness and irregularities, they can be counted by sandpaper with a thin grain, folding it twice. In general, it is better to thoroughly align raw, otherwise you can scratch plastic.

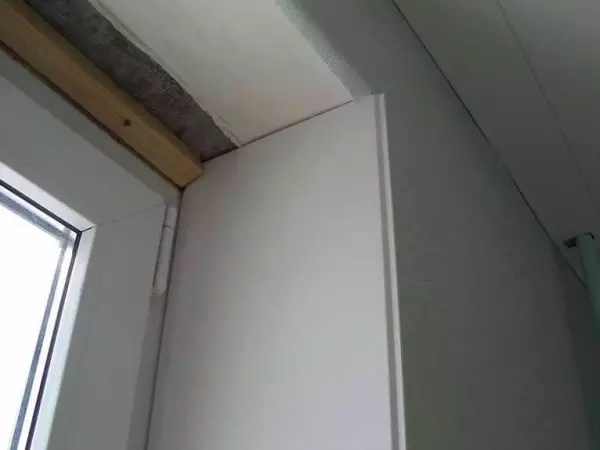

Installed plastic slopes

All, plastic slopes are installed. After the final polymerization of foam, the squeezes need to sharpen, aligning with the surface of the walls. After that, you can remove the protective blue film. As a result, the window will look like this.

Window with discovery from plastic (Sandcic panel)

When installing these plastic slopes, a sandwich panels are used. These are two layers of plastic, between which there is a layer of foamed foaming. By the same technology, you can make the frame of the window from low-cost plastic windows or wall white PVC panels. The most unreliable material - panels: Even the walls are quite easily pushed, besides, if the facial layer of plastic is thin (cheap), then the lintel is visible. In the sandwich panels and plastic windows, there is no such thing. And the effort to sell, it takes considerable, and even there is no lumen of the jumper.

Installation of plastic windows is described here.

Photo report 2: Mount plastic slopes with starting profile

The installation of plastic slopes and on this technology from the preparation of the window opening begins. Cut off exactly foam, we remove everything that does well, we consider dust, if necessary, we take care of the overall printing of the grip.

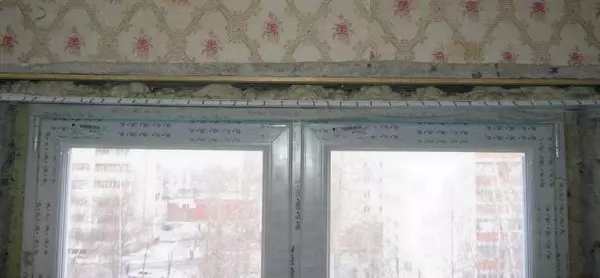

Preparation of window opening

Around the perimeter of the opening, but already near the frame, the wooden bar is fixed. Choose the thickness depending on the distance: it should almost go on the frame. One side of the bar is needed to work out a ruble, making a slope. The angle of inclination of this face is equal to the corner of the slope. You can sprinkle, but it is even more difficult to do, except that there is a circular saw with an adjustable angle.

We make a slope on one of the faces of Bruck

Processed bar screw to walls around the perimeter of the opening. The method of attachment depends on the material of the wall. If the wall is brick, you can try on the tapping screws, a dowel must be put into the concrete.

Finishing the bar

Buy the starting profile in the store, set it up with a long side to the bar, attach. It is more convenient and faster to the plank to fix it with brackets from the construction stapler, if there is no such, you can, with small carnations or flat head self-stairs.

Fresh starting profile

Choosing a starting profile, take a tight. It is more expensive, but you are gently only three meters on the window, maybe a little more. A dense profile will be well to keep plastic, soft - light and the look is turned out to be ugly. Another point - when installing the profile, press it as close as possible to the frame so that the gaps are or not in general, or they were minimal.

Article on the topic: How to eliminate the leakage of a corrugated toilet pipe?

At the top when docking vertical and horizontal profiles, you need to be particularly neat and cut off exactly at an angle of 45 °. If there are small gaps, they can be embedded with acrylic.

Installed starting profile

According to this technology, the installation of reservoir slopes is more convenient to start with sidewalls. In the fixed starting profile insert the panel. They are also better to take from expensive and dense, with a thick layer of plastic. If you put cheap (ceiling), then the front wall is thin, and with bright lighting will be visible jumpers. In addition, such plastic can be used even with a finger.

Insert a plastic panel into the profile

In the width, the plastic panel must be more sloping. If the widths are not enough, two are joined. But then at the place of the joint needed there will be an additional vertical bar, to which the first strip will be fixed.

The panel inserted into the profile is usually longer than the opening. Holding her hand, celebrate the lines of the opening. After removing, cut off the marked line.

Cut in size

We install the panel again, move away a bit from the wall and fill in the mounting foam, trying to pour without skips, but without excess. So that it happened, we start from the far bottom corner - we take from the bottom-up near the nail strap. So far reached the top, the bottom of the foam expanded a little. We carry out a foam line again, but closer to the edge. The closer to the outer edge, the smaller the foam is required - because the panel is installed under the slope, because all the thinner do tracks. Having reached the middle, on the rest of the surface, make a snake and press the panel as it should stand. Align and check. Fasten to the wall with painting scotch. Also set the second part and then the upper. It can also be cut through a paper pattern, and to adjust the edges to the perfect (or almost) coincidence of sandpaper.

Installed window slopes from plastic

By installing all parts of the slope and securing with painting tape, leave until full polymerization. Then, so as not to put the gaps between the slope and the wall, the white plastic corner is glued to liquid nails. The main task is to cut off exactly in the corners. It is easy to glue: on both shelves, apply a thin glue strip, press, passing along, keep a couple of minutes. So they set them all over the perimeter, then, before drying the adhesive, they are also lined with painting scotch and leave.

Installed corners around the perimeter of the slope

After a day, we remove the scotch, the slopes from the plastic are ready.

This looks like a window with plastic slopes.

If there is somewhere slots, they are close to acrylic, as described above. Do not use silicone. In the light he quickly yellow. In a year or two there will be your windows to look awful. Look for a white acrylic sealant and disguise them.

How to adjust plastic windows read here.

Video

Options for installing slopes with a starting profile, screwed to the window frame, see this video.

Video optional installation of plastic slopes without starting profile.

And another way in this video. Here, pay attention to the decoration of the joints of the panels. They were made using a special profile. Could be so.