The key to successful decoration of the floor is a competently prepared draft base. In this case, we are not only about the quality of structural materials, but also about the competent, professional conduct of all works. The correct device of deformation seams will allow an outdoor, rough base for a long time to maintain its integrity, at the same time provide appropriate conditions for operating finishing (parquet, laminate, tile, etc.).

The value of the deformation seams for the floor

The deformation is called artificially created incision in concrete floors, which is intended to perform several functions:

- Increase the stability of the draft coating to dynamic loads. These are temperature changes in the volume of the walls of the building, its shrinkage during operation, directly operational loads;

- Reduce the operational factors for the integrity of the concrete coating.

Although the concrete monolithic floor is famous for its strength and durability, but under the action of structural changes within the screed itself and under the influence of external factors (free deformation of the building, its sediment, operational loads on the floor) it loses the integrity - cracks or is exhausted. The deformation seam is able to reduce the effect of external factors on the draft finish, thereby retaining its integrity.

Classification of deformation seams

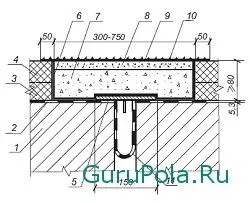

What could be a deformation seam in concrete? Today, experts call the seams of the following types:- Insulating seams - They are used to prevent the transfer of deformation loads on the horizontal overlap from the building itself. Each building in the process of its operation is deformed. This is due to the thermal expansion / compression of the structure, its session, seismic activity of the soil. Insulating seams are cut to prevent deformation processes in concrete floors. The insulating seam makes it possible to move horizontally and vertically relative to the walls, the foundation and colon of the building. The seam organization is carried out around the perimeter of the room along the walls, columns. Its thickness depends on the height of the screed. In most cases, the seam thickness is 13 mm. The deformation seams of this type are filled with elastic material, which retains integrity under the action of increased loads;

- Shrinking seams - The main function of the shrinking seam is to prevent the chaotic cracking of the concrete during its drying and ripening the concrete stone. The ripening of the stone in concrete floors is unevenly. As a result, the upper layer is gaining strength faster than the bottom. At the edges of the screed above, compared to its middle. Cracks are formed in the floors. To avoid them reduce the tension of the screed, spending shrinking seams. Their depth is 1/3 of the height of concrete floors. They are done in the direction of laying a draft finish. The seam should be direct, not to have branches, and the floor cards themselves should be small and have a square shape.

- Structural seams - Cracks in concrete floors can form on the border of contacting the screed of different masonry, for example, concrete in the room is not in one day. Structural seams are organized to avoid a similar phenomenon. It is cut on the border of different layers of concrete. In most cases at the end of work.

Article on the topic: Glue for plywood on the screed: how to glue on the concrete floor

Separately there is a temperature seam. It is a kind of insulating seam and warns the deformation of the design due to its thermal expansion. Temperature incision can be carried out not only in concrete floors, but also in the walls, the roof of the building.

Stages of organizing deformation cuts in floors

Seams, regardless of their type, in concrete floors are organized according to the following list of documentation:

- EAS 9-94 - detailed instructions for the arrangement of draft trim in residential and non-residential buildings;

- SNiP 2.03.13-88 - regulatory documentation for the organization of floors;

- GOST 30353-95 - Here are described methods for testing the strength of floors in residential buildings.

Methods for cutting a deformation seam in concrete floors:

- Slicing seam. It should be carried out on fresh material. Otherwise, not avoiding the appearance of cracks. The surface is pre-prepared. It grinds, necessarily gaining strength to withstand the load from hiking. Recommended time for cutting seam - 12 hours after laying concrete at normal temperature and humidity, 24 hours with reduced indoor air indicators.

- Sealing process. It prevents the decorative coating and adhesive materials from the draft layer. The main function Sealing is the protection of the seam from the penetration of moisture and aggressive media. Seam seal according to the temperature expansion of concrete and operational loads on the floor. The material that is used when protecting the seam: Hernitic harness (it places into the formed cavity), waterproofing sealants in the form of mastic, hydrochpones (profiled tapes that are made on the basis of high-class polymers and rubber varieties). General requirements for sealants: high strength to prevent the edges of the edges, and the plasticity so that the seams can perform their own direct function.

- Decorative design. It is carried out immediately before laying the finishing material.

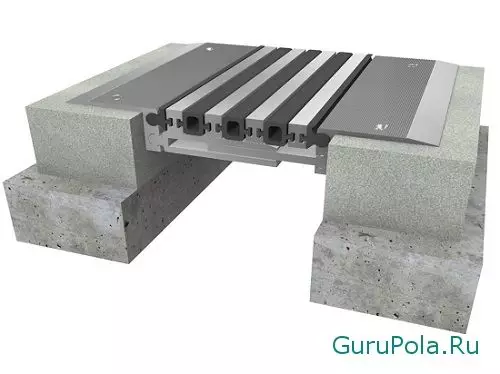

Profile systems

Seam in a modern, concrete screed of the floor can be waterproofing based on specialized systems. This is a set of elements that are designed not only to reliably protect the seam from the penetration of moisture, but also an educated cavity from loads in three planes. The second advantage of the design is compatible with all types of finishing floor finish. Today, the use of specialized systems is economically and practically an expedient solution.

Article on the topic: Door handles Sirius: How to disassemble them with your own hands?

Properly performed deformation seam is a pledge of long-term operation of roughing and finishing floors.