The facade finish is one of the most important events. It depends not only by the appearance, but also the operational characteristics of the building. One way to quickly and efficiently cope with the task is to use the facade panels for the exterior finish at home. They are different, from various materials with various characteristics and sweaty views.

Types of facade panels

The front panels for the outer decoration of the house are a solid group of materials with various technical characteristics made from different materials. To choose, it is necessary to approximately submit their appearance, features and properties.

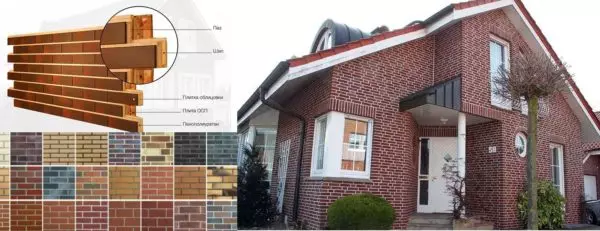

In appearance it is difficult to say which front panels for outdoor finishing are used this time.

For finishing facades of private houses

Not all the front panels are used for lining of private houses. The point is not that "it is impossible", but in the fact that they are not suitable, and almost everything in appearance. More reasons - the complexity of installation and high cost. Today you can find the following facade panels for outdoor finishing of the house of different types. All of them will be listed below.

To choose which facade panels to separate the house, you need to have an idea of their advantages and disadvantages.

Facade siding

All well-known finishing material in the form of long planks mounted on the frame. There are traditional options painted in one of the colors, there is an imitation of a bar, logs, brickwork.

Siding sign all

This is the most affordable material for finishing the facade of the house, but it is too thin, has low resistance to mechanical damage. Another nuance is the sunny side fades, and the appearance does not like everyone.

Ground Siding

The base siding is also made of polymers - PVC (vinyl), polypropylene. Available in the form of rectangular shape panels, some with locks around the edges. Basically, imitate brickwork of different colors and textures, wild or faceted stone.

Cutting siding is made of polymers. The cheapest - from polyvinyl chloride (PVC) and polypropylene

The mass of which the basement front panels are formed, painted in mass, because scratches and other damage do not differ from the face surface. From facade siding differs not only by form and price (more expensive), but also more thick (20-30 mm, against 15 mm) and more believable imitation of stone or brick.

Fibro cement facade panels for outdoor finishing

Fibrocement is an environmentally friendly material that is obtained from a mixture of fibra (small synthetic fibers) and cement. From the mass form boards or stoves, after which they are painted. They are invented in Japan, because they are called "Japanese facade plates".

Fibro cement plates - severe finishing material

Disadvantages - a large mass and painting of the surface layer (cement base is visible on deep chips). Dignity - the material does not burn and burning does not support. If we talk about the price, then Japanese road plates, but there are analogues of Chinese and domestic production with more loyal prices. Chinese, A-VENT groups, by the way, have a good quality. Firm has long been on the market, the reviews are mostly good.

DPK (wood-polymer composite)

Grinding to fibers The wood is stirred with a liquid polymer, a dye is added. From the resulting mass form a plate or board (lining, plaquene). This material is used not only for finishing facades, it makes flooring near the pool, in a gazebo, on an open veranda.

Wood-polymer composite (DPK) very reminds of wood

In appearance, and even on tactile sensations, the wood-polymer composite is very similar to the wood. The difference is that these "boards" do not need to paint or vapor. They preserve the original appearance for a long time. The disadvantage is a considerable mass and a high price. But they are durable, since they are painted in mass, chips and damage (if any) are not visible.

Ceramographic

The appearance of this material is known to everyone, since a more subtle variety is used to finish the floor. Facade porcelain stoneware is characterized by greater thickness and sizes.

Cerambar requires appropriate architecture

Facing the facade of the ceramory is solid disadvantages: the weight, complexity of cutting and installation, which entails the high cost of installation work. And this is a plus to the fact that the material itself is far from sup. The disadvantages also include too pompous appearance, so the architecture must be appropriate. And so, the finish of the house is beautiful, durable, resistant to the effects of climatic factors.

Clinker facade panels

This is a multilayer material. On a layer of OSP (there is not always), a layer of insulation (polystyrene foam) is pasted, and it is a thin clinker tile on it. There is an option only from polystyrene foam and clinker. Produced in the form of rectangular blocks with gear edges.

Article on the topic: Turkish tulle with embroidery - a new way of interior transformation

Clinker facade panels - finishing and insulation in one "bottle"

Material is not cheap, but at the same time longeons and attractive outwardly. In addition, thermal insulation characteristics are improved simultaneously with the finish. This is the only material that goes simultaneously with the insulation, because it is called his still facade thermopanels.

So what is better?

Definitely say which of the listed materials is better not. In appearance, many of them are similar, although there are exceptions. For example, porcelain stoneware or facade siding is not yet confused. But everyone else has a similar flourishing. So in this issue you have to focus on your own preferences.About the operational properties of explicit favorites is also not. All have features and disadvantages. So according to these parameters, you have to select the front panels for the outer finish of the house depending on the properties of the material from which the house and the need for heat / wind / sound isolation is built.

For example, vapor-permeable walls are better separated without foam. He does not hold moisture. At all. In this regard, the use of clinker thermopanels is undesirable. No, you can from the inside to add vapor barrier material. Vaporizoation will block access to moisture inside the wall, everything will be fine with the finish. But the moisture will remain indoors. To remove it, you need a powerful ventilation system, and its device is expensive. And it is necessary to design it even at the design stage of the house. So the thermopanels are used on wood or aerated concrete homes only if they are mounted on the crate. Direct wall mounting disappears.

If we talk about the cost. Of all the listed cheapest way to finish - facade siding. The following is the price - base siding, fibro-cement plates and DPK. And the most expensive - porcelain stonewares and clinker facade panels.

For registration of industrial buildings and offices

In this section we will list the front panels that are more often used to design offices, manufacturing, shopping or warehouse buildings. This does not mean that they cannot be used for a private house or cottage. Simply see them is not too suitable for "home" in a wide sense. But at home with non-standard architecture - in the style of techno, minimalism and other similar things - it is possible to separate it very much. They will look even more unusual.

- Metal panels. Produced in the form of rectangular or square blocks of different sizes. Make them of steel or aluminum. Steel are cheaper, but are subject to corrosion. Aluminum is not corroded, but they are expensive. This type of facade panels for private houses is still used in connection with their "noise", which makes them least attractive from the whole group.

Metal facade panels - for houses of non-standard architecture

- Translucent panels. This type of facade panels are used to finish office high-rise buildings. Make from transparent sheets of Plikarbonate or double-glazed windows - several glasses installed in one profile. In private housekeeping, it can be used for the device of a winter garden, an indoor pool, glazing a large terrace, balcony, loggia. Can be made from transparent material painted in mass or with spraying (mainly mirror, with one of the parties). It is probably possible to arrange the entire house with translucent facade panels, but for this you need to attract the architect - the material is too demanding for aesthetics, and even with difficult technical conditions of installation.

Translucent panels - for the design of winter gardens, indoor veranda, arbors

- Sandwich panels. Produced in the form of large format blocks. These are two metal plates (the facial is very similar to the professional flooring), between which the heat insulating material is laid. Appointment - Finishing of production and warehouse buildings. For private houses, it is not suitable for aesthetic considerations, although you can use for cottages, if there are no too high requirements for appearance. You can build the technical premises - garages, wrappers, hozblocks.

Sandwich panels - for rapid construction

- Aluminum composite plates. One of the varieties of sandwich panels. There is a layer of composite material between two flat sheets of aluminum. Again, not very often can be seen in the private sector. The reasons are two - the high price and the same "office" appearance, although it may come to finish the base, since the alum composite finish is not such a "noisy" as simply "metal".

Aluminum composite plates - two sheet metal with a layer of composite

As you can see, any of the materials of this group can also be used for finishing a private house. The view will be non-standard. If this is what you need, choose the appropriate option.

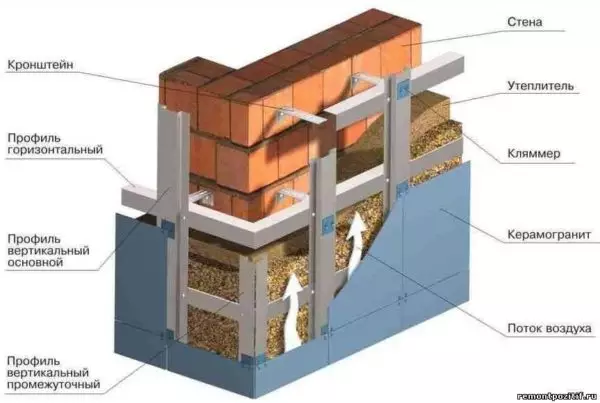

Method of installation

The front panels for the outer finish of the house are made from different materials, have a different form, but they are very similar to installation. In the process of installation, special elements for fastening can be used, but the device is the same - on the principle of ventilated facades. If briefly, the installation looks like this: the grille is going from profiles, and the facade elbows are attached to it.

Fasten the front panels for outdoor finishing at home on a special frame. It is exhibited in a horizontal and vertical plane, after which the front panels are screwed to it for outdoor finish at home.

How to do it

The frame is collected from metal and plastic profiles, sometimes we use wooden bars. Wooden timber - economy, as in most territories a country is much cheaper than metal products. But it is suitable only for materials with a slight weight and not particularly demanding on the installation system.

On bars, you can fix the facade and base siding, fibro-cement plates, DPK, clinker panels. Just before installing wood is necessarily processed by antibacterial and antipyrene compositions. Bruks can be replaced with galvanized profiles for drywall. They also coped with their task. But it must be remembered that for most facade panels, there is its own system of profiles with special fastening elements. The standard mount involves, usually, secret installation - without damage to the face surface. Replacing the profiles on the timber, it is necessary to drill holes for the installation of fasteners and this is not very good, as it disrupts hermeticity.

Frame assembled, there is insulation

The system of ventilated facades is good in that simultaneously with the finish, you can warm the building, improve sound insulation (lay appropriate materials between profiles). Another of her important dignity - the problem of condensate removal is easily solved. Disadvantage: Significant material costs for the fastening system itself (plus to the cost of facade panels).

Let's consider how to separate the facade of the ground siding, fibro-cement and clinker plates. Why these materials? Because the installation of facade siding can be read here, and the above materials are the nearest competitors, gradually displacing it from the market.

Installation of base siding

From the traditional crate for linear finishing materials (siding, for example), the installation of the base siding is characterized by the fact that the lamp must be "into the cell" - the profile / bars should be held at the disk space of the panels. Since the base siding has a view of a rectangle, it should also look like a doom. Another feature is the installation of the start and J-profile. They close the sections of the material, give support, give a finished look. It's not so expensive, so wise, trying to do without them, not worth it.

This is what it may happen

And I also need to remember that there are special corner panels for the design of the corners of the building. They are bought separately, and often have a different color or even another texture. So even a rectangular or square house looks more interesting.

The order of work when installing the basement siding is:

- The surface is cleaned from everything that may fall, fall off. Large holes are closed with a solution, stroking bricks are fixed, the seams are closed, the surface is aligned. The maximum permissible drop is 2 cm per meter.

- The presented base is hampered. You can use a bar, profiles. First, horizontal strips are stipulated - with a step, equal to the height of the panel. The joint of two fragments should have to the profile. In the same principle, the step is selected for installing vertical slats. They are stuffed between horizontal. For greater stiffness, one fragment of the base siding can be installed two vertical jumpers. After all, one panel has a length of more than a meter - 1130-1160 mm, so in the middle it can be fed.

With lining align the walls

- A starting profile is mounted on the lower horizontal bar of the crate. It can be mounted for a bruus of it with minor nails or brackets from a construction stapler, to a metal profile - metal self-draws. It is attached at the corners of the building.

- A fragment of the base siding is inserted into the profile, aligned, fixed around the perimeter with nails / self-tapping to the crate.

- The second panel is connected to the first with the castle. Insert, we achieve a complete coincidence, fix. Next, the process is repeated. In cases where the panel has to trim (the angle of the building, for example), a J-profile is installed. It is slightly different from the starting, is designed just for such cases.

That's all the installation of base siding. After the shap is assembled, the process goes quickly (if the sizes of the panels and there are no problems with shades).

How to mount fiber cement plates

Fibro cement facade panels for outdoor decorations can also be mounted on a clamp of wooden bars, but they will have to pull through, pre-drumped the hole. Station Caracas for mounting fiber cement plates consists of horizontal and vertical profiles. In this case, the plates can be installed on the beammers - special plates for hidden editing.

There is a regular fastening system

Assembly of the carcass

The order of work is:

- First, with a step of 100 cm, the horizontal profile having a look of the letter "g" is attached. They are installed using brackets that adjust the irregularities of the base wall.

- If necessary, the insulation is fixed, on top of which the steam-wind protective film is fixed.

Fibro-cement facade panels for outdoor finishing of the house are mounted on the beammers

- Mount the vertical profile, which are attached to the horizontal scores. Installation step - 60 cm. Vertical there are two types;

- Main P-shaped (wide). They are put in places of joints of the plates. Two neighboring sheets of fibrcement are becoming breeding in this profile.

- Auxiliary (subtle). Installed in the middle of the sheet, in the corners and on the slopes. Those in the middle of the sheet are needed to install fasteners and for the support of the middle plate.

- Fix fibro-cement plates. You can use self-tapping screws, making holes in the surface or using curvators. About the attachment methods in more detail below.

When attaching self-assembly they are screwed up so that they get into the profile. At the same time, we must try to get into the technological recess (seam between the "bricks"). In this case, the mount is less noticeable.

Fastening fiber cement plates on frame

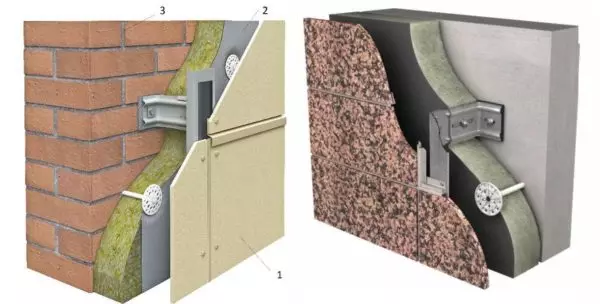

Fastening by curvators - secret. At the same time, the surface of the plate is not damaged. Clammers are attached to profiles and keep plates with special tongues. The order of work is:- Putting the bottom sump.

- The starting plank is attached.

- Corners are installed.

- The first row of plates is placed in the starting bar, the top is fixed with the bits. They put them, trying to get into the installed profiles.

- The next leaf relies on the protrusion on the beammers. On the reverse side of the fibrotent plate there is a special seal that guarantees the tightness of the connection.

This method of installation Invisible - Clemmers are located so that they are behind the panel, and the protruding tongues are closed by the next fibro-cement plate.

According to this principle, most of the ventilated facades are mounted, which include all or almost all the front panels for the outer finish of the house. The form of profiles and beammers is distinguished, the installation step, everything else is very, very similar.

Installation of clinker facade panels

As already talked, any front panels for outdoor finish at home are mounted on one principle, because we will talk only about the differences characteristic of clinker thermoblocks.

Clinker panels (thermopanels) go immediately with insulation

Features of choice

The main difference is that they go immediately with insulation - expanded polystyrene. When they choose, it is necessary to choose not only the quality of the clinker (when the metallic sound is hit, the sound must be ringing). It is important to choose the thickness of the insulation. The dew point should be in the thickness of the insulation. This is very important for normal operation (they will not mock and freeze the walls, the house will be warm and dry).

Transformation of an old house

The second important point: on the smooth walls (the height difference is not more than 3 mm), they can be mounted without crate, straight to the wall. It is necessary to use long dowels or self-tapping screws (when installing on wooden walls). Otherwise, a frame from a wooden bar, which compensate for all irregularities.

What is the difference in installation

More significant differences in the installation:

- Each facade thermopanel has a certain amount of holes molded in the factory conditions. When installed on the crate, you do not need to drill. The panel is installed in place, its position is checked, the screws are tightened. When mounting on the wall, you must first install the plugs for the dowels. Then the order of work is: the panel is put, a thin drill is planned holes in the places of installation of fasteners, the panel is removed, they put the plugs. Again the panel is put on the spot, the dowel is installed. The process is long, and even when re-installed, you need to set the unit so that the fasteners coincided.

- Facade clinker thermopanels have a plug-in / ridge type. Inserting them into each other before the stop, seeking the lack of gaps and cracks (you can face the palm, but not by the insulation, but on the surface, so as not to damage the spike).

The harder in the corners

- Screw fasteners should not be stopped. Fastening holes are made with such accounting to ensure freedom of movement. This is necessary when temperatures change - to compensate for thermal expansion.

- Fasten the facade clinker panels should be from the corner.

- First there is a first row of panels along the wall. When it is installed, it is necessary to strictly monitor the horizontality. Then the whole finish will be mounted without problems. A starting work schedule can simplify. It can be a flat board, a bar, a profile that is assembled so that its top edge is a support for the first row of the front panels. The second row is set after completed the first.

- When forming angles, cut off the edge of the panel. The res is located exactly at 90 °. Then the tile and layer of the insulation under it are cut at an angle of 45 °. After folding the panel cut in a similar way, we obtain an angle of 90 °.

- When around the window and door openings, the panels are cut into so that they can then be docked with insulation. The joints of the joints are then filled with mounting foam.

- After mounting, the seams are wiping. Consumption of grouts - about 2 kg per square meter.

Clinker facade panels for outdoor finishing at home after installation look like a house built from clinker bricks. Neither the first, nor in the second look of differences you will find. Is that laying too perfect.

Article on the topic: Metal primer. Technology performing work