For the construction of a residential building, the options for wooden construction are most often considered. Wide distribution received a bar. Its application allows you to facilitate the process of building a church.

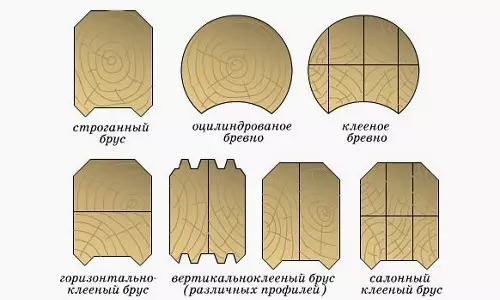

Types of profiled timber.

The build technology of the house from a bar may differ quite strongly depending on which profile has a building material.

Features necessary tools

Distinguish several types used:

Scheme of training logs for gram assembly.

- Construction - sawn, or, as it is sometimes called, "shaggy" timber. In the section represents a square or rectangle.

- The profiled timber - differs from the construction presence on the top and bottom face of the system of protrusions and grooves that ensure the conjugation of individual crowns when the wall is erected.

The design of the conjugation line provides for laying a layer of insulation. Sometimes the conjugation is carried out without the use of auxiliary materials, which is called dry.

The manufacturers have a profiled timber can be produced two varieties:

- The whole - made of a single array of wood;

- Glued - in production, the gluing of individual lamellas is performed.

When assembling a brusade house, regardless of the profile used, you will need the minimum necessary set of tools:

- saw;

- drill;

- hydraulic or laser level;

- Stapler construction;

- sledgehammer.

In addition to the above assembly tools, auxiliary materials are needed:

- insulation interventian;

- Wooden brazening;

- If necessary, metallic studs with a diameter of at least M12.

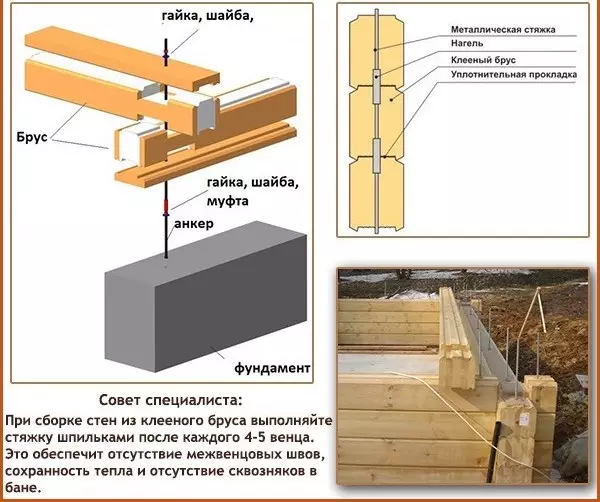

Technology tie glued bar with studs.

When erecting a log house from a profiled bar, most often at the factory, according to the project, a home complex is preparing. The output is the actual set-designer, where each detail is numbered. Using the attached design drawings, if you have at least minimal experience with the tool, it is relatively easy to build the entire design in place.

The main rules for storing building materials on the site is to protect against precipitation and moisture from the soil. Therefore, it is best to organize the place of temporary storage under the canopy. To prevent the soil moisture from entering, all the details are stacked for temporary stands. The distance to the level of the soil should be at least 20-30 cm.

Article on the topic: Repair of cracks acrylic bath do it yourself

Practical recommendations

The process of assembling the brusade cutter is similar to the harbor assembling from the usual log. The foundation is stacked by waterproofing in 3-4 layers. On top of the waterproofing, a mortgage board and a bustling crown is installed.

Here is an important point that determines the quality of the entire subsequent assembly is the installation of the entire crown of exactly one level. No matter how well the foundation has been completed, it will still have drops in height, sometimes very significant. These drops can be eliminated, laying regulating gaskets and checking their position with a level. Another way to adjust the base is the pointed board to obtain a horizontal surface.

To continue the assembly process, the corners are rigidly fixed by building brackets, after a certain distance (1.5-2 m), but at least two points on the wall, the fastening to the foundation is carried out using metal anchors.

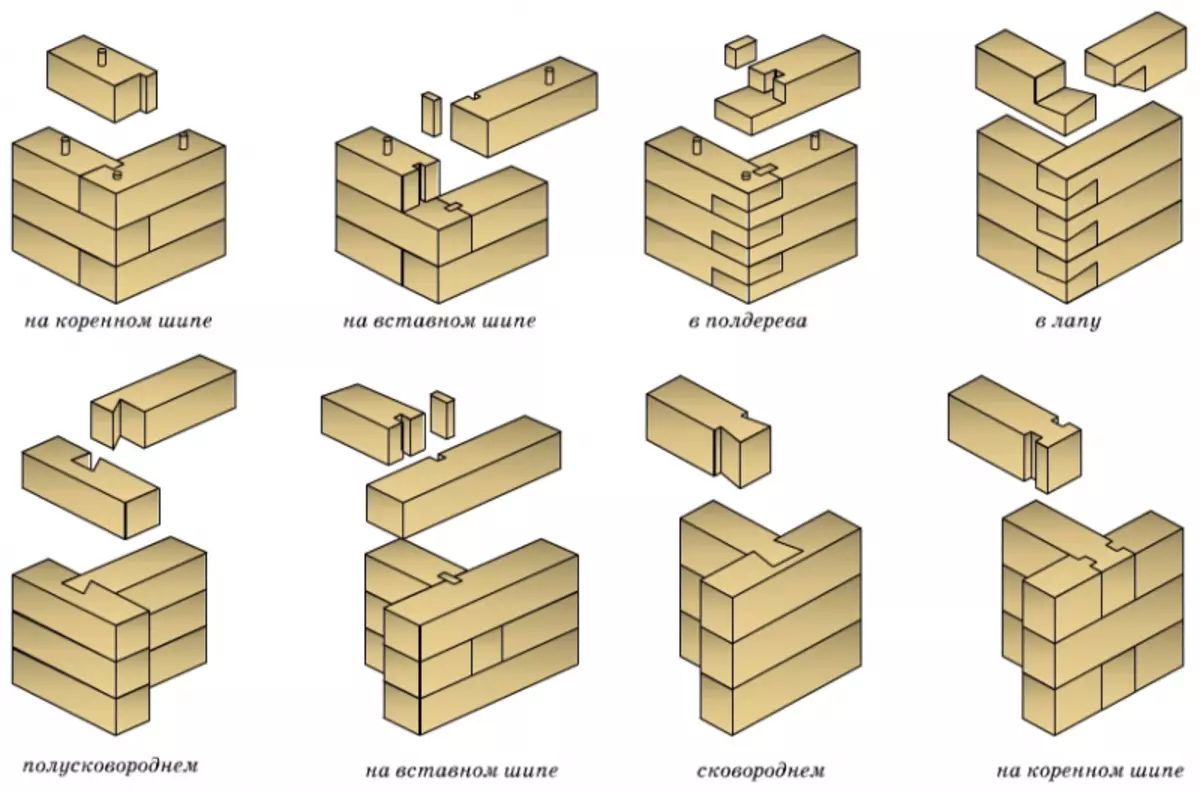

Methods for connecting timber without a residue.

The interventian seal is stacked on the castle compound and on the entire surface of the bar. To prevent displacement when conducting installation work, it is fixed using a stapler.

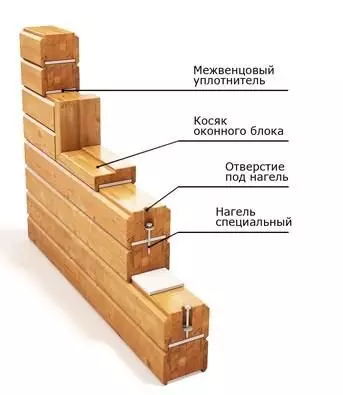

The construction of the walls of the house from the bar comes through consistent laying of the crowns in a predetermined order. To give the stiffness of the design and prevent deformations in the future through certain intervals (1-1.5 m), the holes are deplorable, in which the sledgehammer tension is installed from solid wood (usually used birch). The length of the brazen should be sufficient for passing through 2, a maximum of 3 crowns. At the same time, its length should be several centimeters less than the depth of the mounting hole.

Crubble can be given even greater rigidity, additionally bonding the crowns with rifle studs.

Screed with studs are carried out at once all the crowns. Studs are installed in the places of the furnaces, along the windows and doorways. With a high length of the walls, the spurla installation interval is approximately 2 m.

Article on the topic: Several ways of fixing cable to the wall

The sequence of assembly of walls from a bar in this case is as follows:

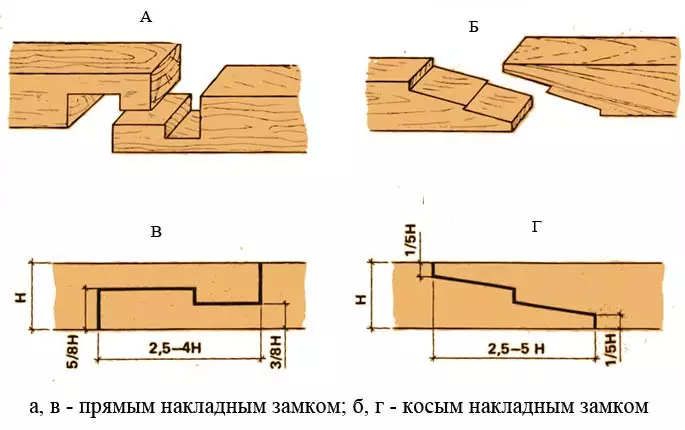

Bruz connection along the length of a direct overhead lock and oblique overhead lock.

- In the adjacent crowns, the holes are pre-drilled a little more diameter than the stud;

- sufficient depth of the groove to install nuts and washers;

- The stud with the help of nuts is fixed in the drilled hole of the lower crown;

- Wearing a bar on the hairpins;

- fitting at landing places and checking the level of horizontal installation;

- fixation of the installed timber by tightening nuts on studs with simultaneous climbing a sledge hammer through a lining board;

- Checking the horizontal position of the location of the bar and, if necessary, additional adjustment of the fastening tightening.

Sometimes instead of studs, screws are used with a head under the end key, tightening two adjacent crowns. The installation of self-tapping screws is carried out in places of intersection of BRUSEV and with an interval of 1-1.5 m. However, such a version of the screed is even easier in execution, but has a smaller resistance to deformities.

The combined method of using studs and aging allows preventing the wall deformation in vertical and horizontal directions, respectively.

Additional moments

Device wall from timber.

When construction from the sawn timber, analogies with a log even more. Here the corners of the cut can be collected both in the paw and in the bowl. The wrist of the inner walls, beams and floor lag is made in a frying pan (according to the visual form, such a connection is similar to the connection "Lastochka Tail").

Mandatory in this case is the fastening of the crowns with the help of aging (spikes) and studs. It also affects the partitions, as they must be as fortified as much as possible not only the design itself, but by themselves.

To ensure thermal insulation and the dense connection of the adjacent crowns on the entire surface of the bar, a layer of insulation is stacked.

During the construction of such a material, the walls give an inevitable shrinkage. And periodically need to screw the nuts on the hairpins.

Article on the topic: What can be made of plastic bottles

Regardless of the type of material used, when the house is erected, a number of rules must be strictly respected:

- In the process of installation, each bar must be installed in its place and recorded on it using fasteners of structural features or auxiliary devices. It is necessary to strive for the maximum possible installation accuracy.

- All fixing structures must necessarily provide a free shrinkage of the walls of the house and prevent the change in the geometric parameters of the bar.

- All work related to installing brazen should be made after fixing the timber.

- Holes under the brazing must be made strictly vertically. This is possible when using drilling conductor for drilling.

- Using screw screeds is extremely preferably. This will avoid deformations in the vertical direction.

- After the assembly process is completed, the interwicp seams must be cocked when using a natural seal or protected with a special sealant.

The execution of the listed rules allows you to get a reliable warm house that you do not have to periodically patch and repair and which can be rightfully proud.