The production of log cabins provides two main variants of laying logs: "in the paw" and "in the bowl". The most common in modern construction cutting into "in the bowl", or it is also called "in the region." The technology of cutting a cut "in the bowl" is made with the balance of the log, protruding the corner of the construction, and the word "circulating" means a round shape of the elements. The protruding end parts of the logs are approximately 30 cm. When using this method, there is a significant overrun of the material, but due to the proper ends, the structure is protected from wind and from the penetration of the cold at low temperature.

The manufacturing technology of wooden log cabins provides two options for laying logs: "in the paw" or "in the bowl".

Such a method was used by our ancestors, since in the process of work does not require complex tools, it is simple and unemployed.

Used tools

It:

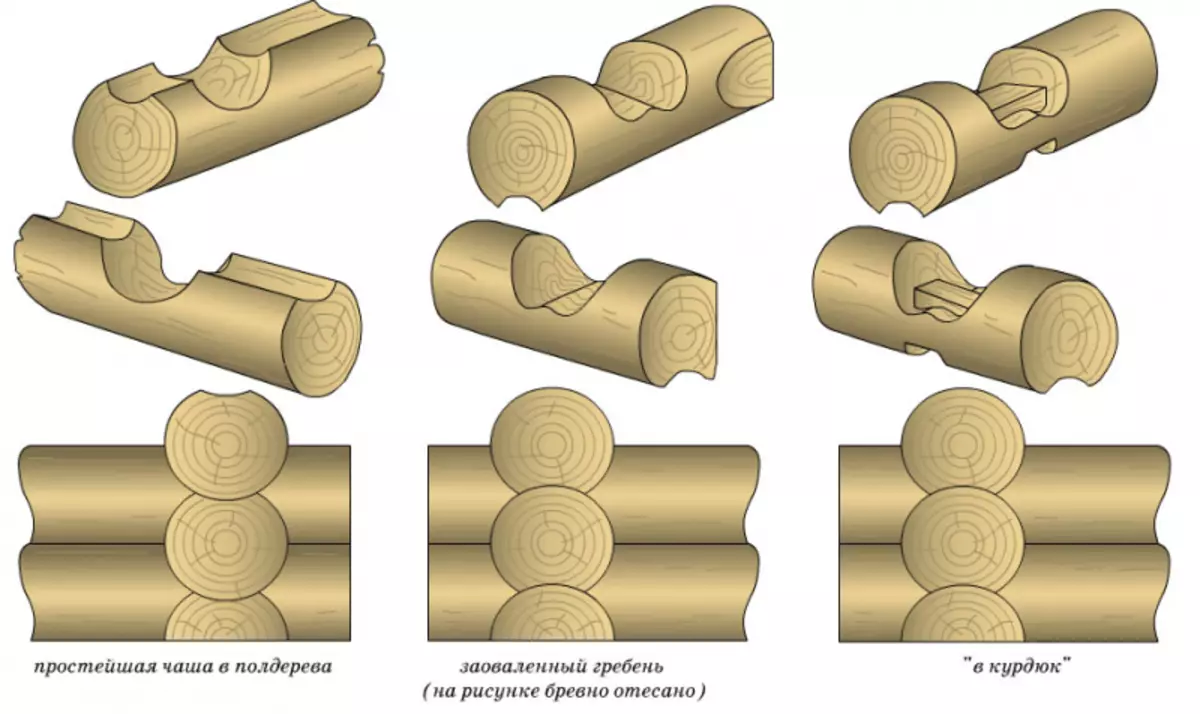

Types of log connection.

- ax;

- chainsaw;

- carpentry chisel;

- damn

- a hammer.

If it is not possible to get the line, then it is easy to make it yourself. To do this, a bar of a square-shaped tree with sizes of the sizes is about 30 mm and in length about 20 cm. The edges should be drowning and sanding the sandpaper. This method is most practical.

To perform work, two metal stripes will be needed, the thickness of which is 3 mm, and the width is 20 mm. It will depend on the cross section of logs and the size of the bowl - from 20 cm to 30 cm. Using the metal hacksaw, it is necessary to sharpen one of the ends on each of the bands. With the help of Scotch, you need to consolidate the uncontamined ends to the wooden bar, which will serve as a handle for about 1 m.

When festers, the bands and longitudinal grooves are placed on the required size. In order for the strips during the work, they are fixed, they are fixed using bolts or spills with carvings. At the same time, on the strips is made on one hole and the bolts with nuts are placed in them. With the help of nuts, the size is adjusted. So the homemade trait is made.

Article on the topic: How to repair a castle of plastic door

Performing cutting cut into a bowl

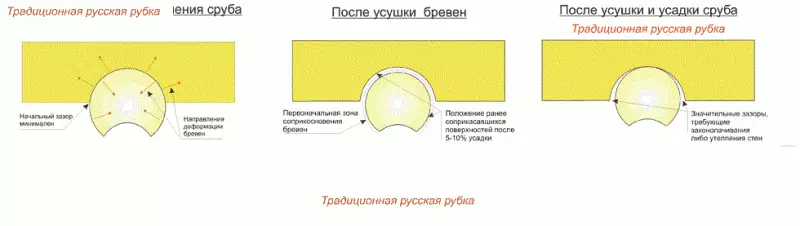

Deformation of the log when cabing a traditional Russian bowl.

For convenience, during the operation of the log, the cross will be preliminarily stacked, and for the greatest stability, they are recommended to fix the brackets so that they do not spin when working.

The cutting bowl follows this size so that its bottom coincides with the upper edge below the lying log. For convenience, it is recommended to perform on these places inspired, relative to the wall axis in the middle of the bowl on the required depth. Next, the bowl is cut down, with the form of the lower element.

Above the busting crown is the bold and weathered all-layer logs. The installation process is to lay the two logs in advanced bowls. After that, they are aligned and, if necessary, fix the brackets from both ends to the underlying transverse logs. From the end side, you visually need to determine the size of the gutter, with which the upper element is mounted on the underlying log. The desired size is displayed. Visually choosing the middle of the feature, spend along the log along the contact line, as a result of which two scratches are formed in parallel passing: one on the lower log, and the other on the top. In the same way, with the help of the feature, markings from the inside. Remove locking brackets. Further, the log turns over so that the markup is from above. Pull the top logs from the bowl. Make fixation, but so that they are subsequently easy to dismantle.

The deformation of the log when cabing with a Canadian cup.

On top of the log visually noticeable two scratches, for which it is necessary to push the wood, as a result of which the excavation should turn out. The dimensions of the excavation must repeat the contours below the lying element.

When the excavation is made diagonally and the entire length is recommended to make notches. The nose of the ax must be immersed before the bottom of the future gutter, but the blade should not touch the scratch. Many with the cutting of the excavation use the heel - the other side of the blade.

The devices are made similarly from the opposite side where scratches are placed. After carrying out such a process, a piece of scubons are selected.

During shocks, the blade of the ax should be directed along the fibers of wood.

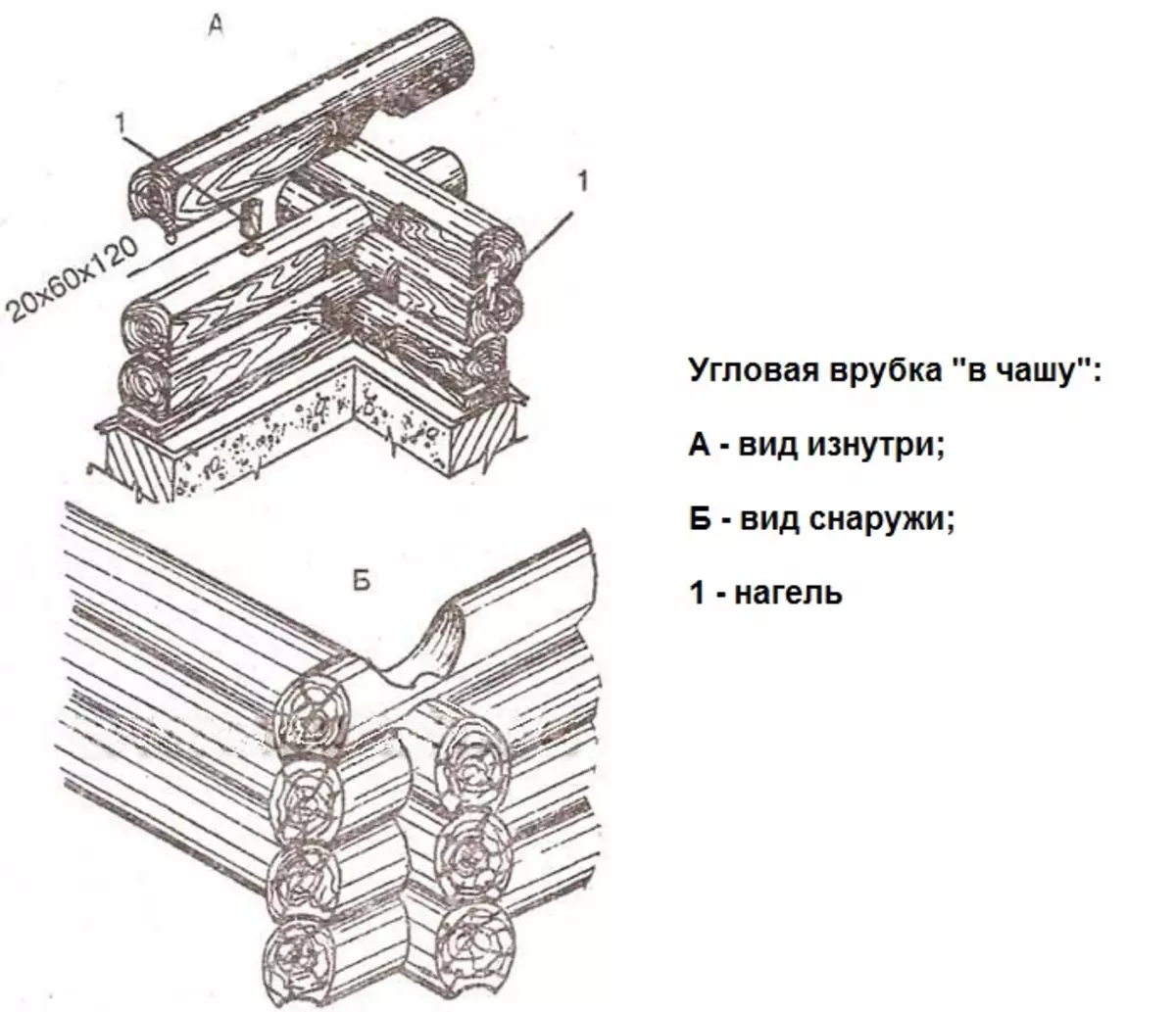

Corner Wide "In the Bowl".

Article on the topic: rubber, nitro, silver and hammer paint for metal for metal structures and internal works

During operation, only the nose of the blade is used, thanks to this, the blows will be more accurate. At the same time, the following movements are made: cutting the ax and sawing wood.

After cutting down the middle part of the log surface, the surface of the excavation must be required. Usually, the recess is performed by a width of 10-15 cm. It is necessary to prepare the bowl itself. To do this, it is performed in it from both sides from the top edge of the lower log before the markups performed. If necessary, the bowl is drunk from the outer and inner side.

Laying logs in Siruba: Recommendations

When laying, it is necessary to control the accuracy of fitting logs in a logber. Making the installation of logs on each other, the lower packs of charcoal. Further, it fell onto the top log with a finished seal and immediately removed. After all this procedure, you need to examine the log on the subject of adorubs. Spain places of soot and will be adorns, if they are present, they are shy. The more densely the upper log, the warmer will be a cutting structure.

Scheme of the extension "in the bowl".

Mounted on top of the logs must be fired to give a round or oval form. To prevent the logging of logs and to give the strength of the entire cut, the crowns are bonded by brazen. Begroes are made of solid wood and should be well dried. They are installed at a distance of about 2 m. It must be remembered that each of the crowns should be fastened. When laying the logs, it should be time to use a plumb to check the vertical walls.

A gap of about 1 cm may form between the gap and the excavation, the insulating layer of the packley or moss will be laid in this place.

As the log will be installed in place, on it, with the side, with the help of the ax, marks are made necessary for the location of the brazers. Over the entire length there should be two or three. After dismantling their logs, they are turned over to the chute up and the holes are made in it in places opposite notes. The holes are performed using chisels and inquins and are 7x2x5cm. In the nests are clogged with brazers that additionally fasten their logs with each other. The strength of the structure gives the strength of the design, their installation in areas where window and doorways will be placed.

Article on the topic: Homemade outdoor and pendant lamps do it yourself in one style

Wall insulation moss: recommendations

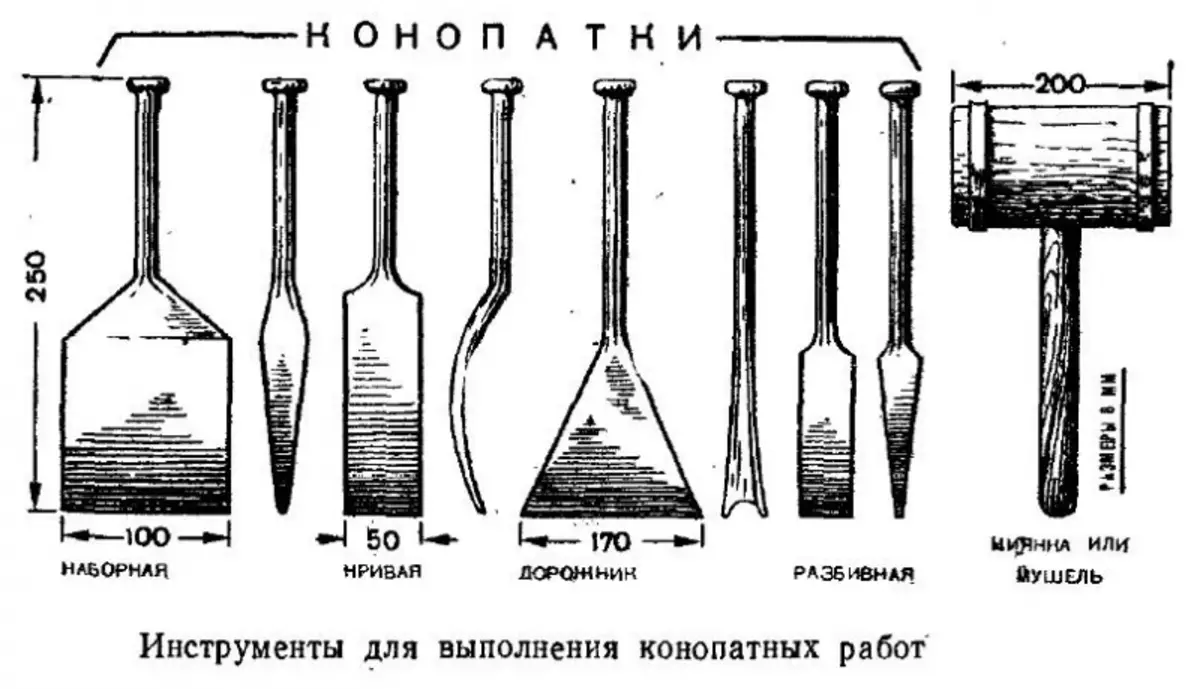

Laying moss between log logs is made by special tools.

Further stage will be a moss warming. With windy weather, so as not to blow up the insulation, the ax is pinched along the fibers. Why is Moss? According to the characteristics, it is better than pacles, as the most durable, smells incense and for a long time will enjoy the air in the house.

Moss-baked logs are stacked on sticking brands. How they will fall into their place on them knocking on a wooden hammer to the full sediment. Colding must be made with caution so that the log is evenly sitting, and do not break out. Over them, the blows are produced in turn.

The final pantop is produced after the device of the furnace, but it is better to have time to occur before the winter period. Konopka is made of wood and has a blasting form. In the case when it is blown up, it is pushed with an ax, after which it can be continued.

Further laying of logs in the Siruba are produced using ropes, which facilitates the installation of the upper crowns. When the log house is born on a separate pad, it is separated into two stacks in height. One of them is closed in the center of window openings through elements, and after their installation, they are already on the spot they are drunk under the openings.,

During the log cabin, the work is produced by two people, for each angle there are one. Fitting logs are produced together, but one person works when samping a gutter. While the sample is being conducted, other workers are preparing to rise other chub elements, made braided and fulfill other work.

So, the assembly of a log "into the cup" is made. Through the use of natural materials, such houses do not require additional finishes. But to extend the life of the log, it is recommended to be treated with antiseptics, as well as a thin layer of varnish. It will protect the wood from the impact of the natural environment, and then the house (log house) will delight with its warmth and comfort not one dozen years.