Penofol is a material that is made of foamed polyethylene, it is used as a pair-and heat insulator. In addition, the foil polyethylene layer on the top of the foil polyethylene is able to effectively reflect thermal radiation. The material does not have praises, it means that it will not pass the air, giving the insulated room the characteristics of the thermos.

Before the insulation of the cold floor, the foam must be putting a clay and make a screed on it.

The insulation of the floor by foam is often produced in the space of the sauna and bath, which should store hot and wet air for a longer time as possible. It perfectly copes such a material with insulation of cold floors, which are made, for example, from concrete.

The first floors of the buildings most often need more effective insulation, wherein the Penofol should be used.

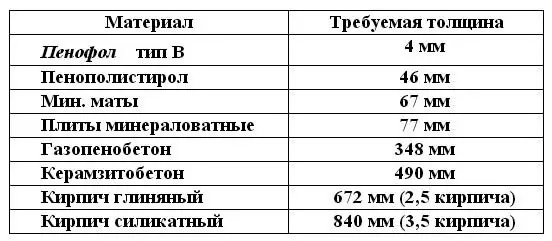

Comparison of foam with other materials.

It is used in the installation of warm floor systems. However, it should be remembered that the technology of insulation in each of the listed cases should be their own.

The foamed polyethylene in the penofole cannon contains air, due to which it becomes possible to provide thermal insulation. The foil layer in all modifications of this insulation is the same, but may be or only on the one hand, which is determined by the labeling "A", or on both sides, then the material has a "B" labeling.

It can be preferred to carry out such a foam, which on one side contains foil, and on the other - the adhesive layer, which ensures the ability of the material to stick, this type will be determined by the "C" marking. It is possible to carry out thermal insulation of the floor by foam, which has one layer of foil, laminated on top of polyethylene, to determine such a heater will help the "ALP" marking.

If you decide to prefer as the insulation of the Penofol class "A", it will be fixed to another insulation, which can perform a foam or styrene. The mount must be made using a stapler whose actions are able to replace ordinary nails. The material of the class "C" can be fixed directly to the base. Heat the floor by foam of class "B" can be by autonomous fastening of the material.

Article on the topic: What is thermocons? How to use thermoclaim?

Tools and materials for insulation by foam

- Cement.

- Ceramzit.

- Sand.

- Aluminum tape.

- Level.

Features of laying foam

If it is supposed to be insulated with cold floors, it is originally to pour it with a concrete tie with clay. To do this, it follows the space between the beacons to lay evenly clamzit. After the layer obtained, it is necessary to shed cement milk. This procedure will ensure the grasp of the material, in addition, the ceramzite will receive a coating in the form of a film. Moreover, when cement dries, on the surface of the clay can be moved. Then the work can be suspended for 24 hours, and after the title period, it will be possible to begin the arrangement of the floor screed itself.

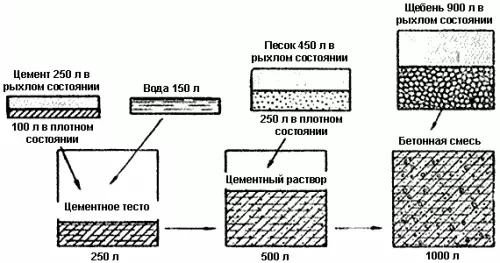

Scheme of mixing solution for a screed.

As an alternative solution, a foam can be made by a foam, which should be stacked with a thickness of 5-10 cm. The foam should be strengthened (can be used with glue) a layer of foam, for which the material type "A" or "C" is suitable. It should be carried out with the allen on the surface of the walls, the nest must be 10 cm around the perimeter of the room. In order to ensure high reliability of connecting joints, you should cry with the help of aluminum tape.

When the insulation of the floor is performed using a foam, the material will protect the design from moisture that will not be able to pass through it, it will cause the water sedimentation on the surface of the insulation. In order to avoid this, over the foil layer of the insulation should be left a small space that will ensure the ventilation. To do this, to the surface of the insulation material from the foil, it is necessary to fill the rails whose width can be equal to the limit of 1.5-2 cm, they will be able to create space for free movement of air masses.

The same function is capable of performing lags if it is supposed to be equipped with a wooden coating. Lags and rails must be predetermined by antiseptic composition, replaced which can traditional olifa. It is necessary to mount them for the entire length of the room, retreating from the walls of about 2 cm, while observing the step between the mounts from 35 to 40 cm.

Article on the topic: Door closer with your own hands: How to make and install?

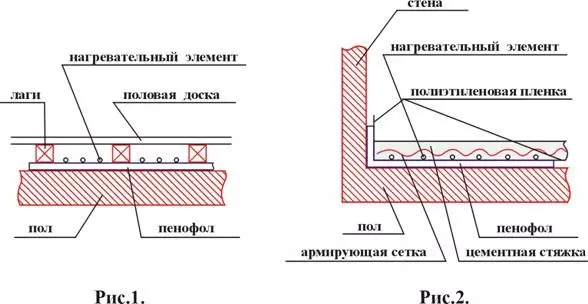

Floor insulation options by foam.

The horizontal installation should be monitored by the level, and the lags that begged, should be led by split rails. At right angles with respect to lags, the boards should be strengthened, the thickness of which should be 2 cm, and on top should be placed with a thickness of 12 mm.

It is permissible to apply the phaneer whose width is 6-8 mm, but it will be necessary in this case to lay in 2 layers. Linoleum or laminate can perform as an finishing coating.

If a wooden floor is staminated in the room, even if there are cracks on its surface, it is not necessary to get rid of the insulation with foam. Penofol in this case should be put, turning the foil up. The material for this process should have a thickness of 1 cm. On top of the insulation, you can pave any material that is capable of ensuring the firmness of the base.

It is excellent for this organite, and any material can be used as the finishing coating at the request of the master, for example, linoleum can perform. Then insulation and finishing coverage will be a budget option.

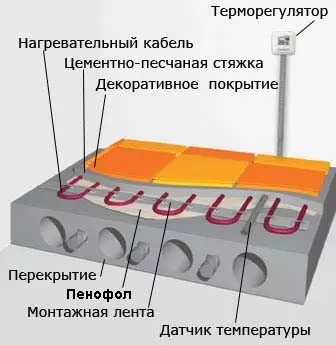

Finding foam together with a warm floor system

In order for the insulation of the floor to be even more efficient, it is possible to use foam in tandem with a "warm floor" system. To do this, on the draft floor, turning foil up, a foofol should be laid, while thermal insulation of the type "A" or "C" can be used. Next, it is necessary to lay the heating elements, paving the lags between them, to which the flooring is sprinkled.

Warm floor diagram.

If the heating elements are assumed to be poured by a cement screed, which may further include the tile laying as a decorative finishing coating, then the Alp type insulation should be applied, this is due to the fact that the cement solution acts as an aggressive medium for aluminum coating, which is used in the manufacture foam (second scheme).

Article on the topic: How to close the gaps in the floor between the boards: Wooden shuffle, seelings of holes from mice, sharpen seams plywood

Warm floor can not only effectively, but also multifunctional. So, ensure the insulation of the floor from the shock noise will allow laying of a material with a reserve of 10 cm on the walls. So, you can equip the "floating floor" system.

The floor should be securely hydro and steam insulated, for this joints of the canvas need to be punctured by an aluminum ribbon.

After mounting the heating elements, you can start laying the reinforcement grid, only then you can start the arrangement of the screed. After the pouring was carried out, the edges of the insulation should be neatly trimmed. After it is necessary to warm the floor for quite a long time, then it can be commissioned.

The insulation of surfaces with foams provides hydro, heat and noise insulation, reducing the level of shock noise by 20 dB, which ensures uniform heating caused by the reflecting properties of the foam.

Before insulationing the floor using a foam, one should familiarize themselves with the features of laying one or another type of insulation of this class, since the incorrect laying technology can cause ineffective thermal insulation.