Building a house from one brick in our climate is not the best idea: it is too high in his thermal conductivity because of which the walls should be thick. But the use of it as finishing material is already more economically justified: the lining of the house with bricks, with proper insulation, will help and save on heating, and the appearance will give the structure of "capital". If the walls are expelled from foam block or other light and warm building blocks, then such a finish will also be windproof. They look with bricks and wooden houses, but in this case there are its own features: it is necessary to ensure the conclusion of vapors from wood, otherwise - mold, fungus and expensive repair with a complete breakdown of the finish.

What brick to use

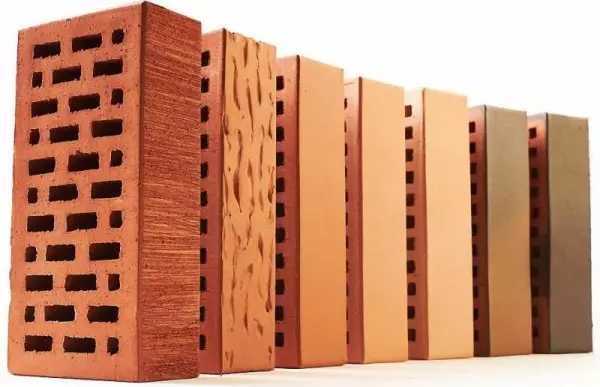

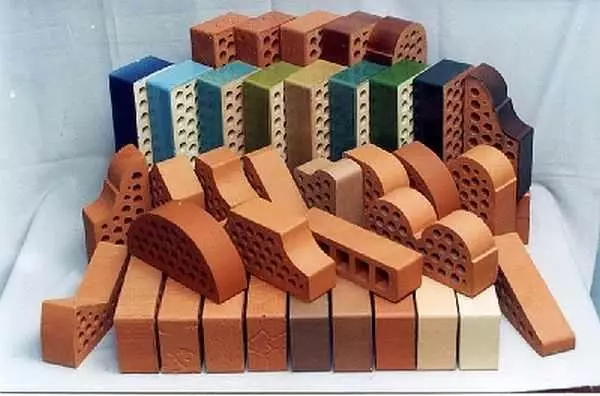

Facing brick is released by various technologies, thereby it has different characteristics and prices:

- Ceramic. Of all the finishing, he is the most inexpensive. Of the minuses you can call high hygroscopicity: 6-15% depending on technology and batch. In the pores of water during freezing expands, causing destruction, the brick begins to crumble. Even a special finishing, in which the beds in the factories (the part that turns out to be outside) is specifically protected. Exit - after laying to coat with a wall with hydrophobic composition. Only those that do not form a steamproof film. When choosing, pay attention to this: excessive moisture should be output. Frost resistance of ceramic facing brick 25-75 cycles (how many times it transfers the size / freezing without worsening the qualities). The higher this indicator, the higher the price. It is explained by large costs in production.

Ceramic facing brick can have not only a smooth facial surface. There are also different shades that allow folding patterns.

- Hyperpressive or debugging. This type of facing brick is not found in the fruit, but by pressing. Its composition is no longer clay, but lime with various fillers and pigments. The possibility of using pigments allows you to get a wide color gamut. The facial surface is often non-linear, imitating wild stone. Looks decorative. But such a nonlinearity threatens to resolve: an uneven surface, water is more abundantly crossed in the pores, it freezes in frost. It is treated as well as in the case of ceramics: hydrophobic impregnation. Frost resistance of high-quality bump brick is declared by producers from 75 to 150 cycles.

Hypersded or bumpy finishing brick looks in wall cladding decorative

- Clinker. This brick is also ceramic, but special technology gives it very high strength and density. More denser material is much worse absorbing water. To operate, this is good, but when laying leads to difficulties: so that the wall does not "swim" to put on a hard, low-plastic solution, and it is more difficult to work with it. Another minus, limiting the widespread dissemination of a different material characteristics: compared with previous materials, it is expensive: prices are 50-150% higher depending on the manufacturer. Frost resistance of clinker - from 100 to 150 cycles. Clinker lining at home brick - the pleasure is not cheap, but the most attractive in appearance.

High strength clinker brick allows you to create nonlinear decorative elements when cladding

- Silicate. The cheapest, but also the most "fast spill" of facing bricks: its frost resistance - 25-50 cycles. It is better spent warm. Not much, but still: the average thermal conductivity of ceramic 0.16, silicate 0.18. In addition, it is heavier: on average weight of ceramics 2.4 kg, silicate of the same size is 3 kg. Little weight requires a more powerful foundation and winnings in price (silicate cheaper) is not so big. If we consider that the cost of heating will also be greater, then the dubious thing is at all. Cover the house with silicate bricks is advisable in the warm regions. In the northern it is quite unprofitable.

Facing at home from silicate brick is the most inexpensive, but, unfortunately, the most short-lived finish

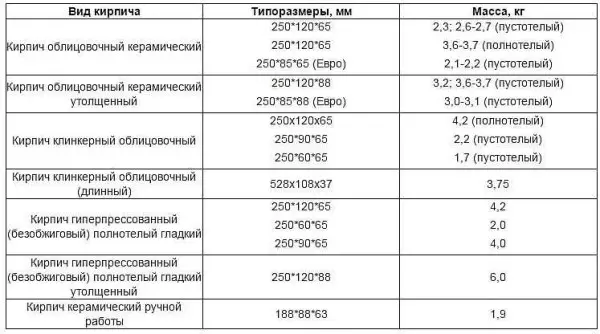

Choose a type of brick - not all. You must also pay attention to the size and shape of the holes. Full finishing brick is rarely used: it is more expensive, more weighs. On average emptiness occupy about 28%, but they are large and small. With equal characteristics, give preference to bricks with small holes: the solution will not fall in them. This will reduce the flow rate of the masonry solution, and the strength of the masonry will increase.

If the house is awarded the house with hypercasted brick, it has been produced should be no earlier than 15-20 days ago. During this time, he gains basic strength (about 80%) and it can be transported and loaded without fears.

Please note that when stored on the packaging bricks should not fall water. This is especially true if they gathered him to leave for the winter.

Standing at home siding is described here.

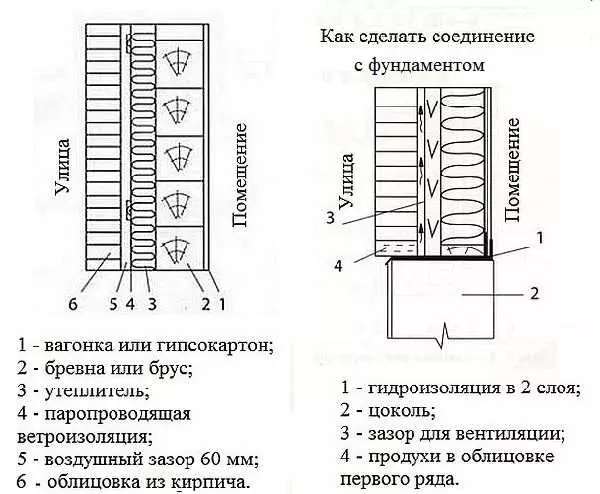

How to Cover Wooden House (Bruce, Log, Skeleton) Brick

Most difficulties arise when finishing with a wooden house brick: very different characteristics of the materials, it is not easy to make a good bundle. The whole secret here is the need for a ventilation gap between the facing and a layer of the insulation, which is usually hampering onto a wooden wall. A wind insulation of the heat membrane is laid on top of the insulation. Mandatory condition - it must be vapor-permeable (Izosan A, Izospan AS, Taiveques Hausreep, Megazole SD, etc.). Only under such conditions in the room there will be a normal humidity and rot rotals and fungus between the facing and the wooden wall.

Instead of windproofing, you can protect the surface of the insulation of fiberglass or glass cholester. With a sufficient thickness of the wooden walls, the layer of thermal insulation is simply absent, wind insulation and the ventiosor remain.

How to put a house with bricks with your own hands: facing device

Ventilation clearance must be at least 60 mm. It stretches from the very bottom of the wall - it begins after the base - and to the top. To ensure air flow in the first row, ventilation products are made through which air comes. Under the roofs in the cornice part arrange the outlet holes. Square of ventourcery 75 cm2 for every 20 m2 walls. Production in the lower row can be made in several ways:

- put on side brick with through holes;

- Partially filling out the lateral seams with a solution (when laying the solution to put the line, then take it out);

- Make two or three holes and install grilles.

Regarding which insulation to use. The most acceptable option is mineral wool in mats or rolls. The use of foam or polystyrene foam is undesirable: they do not conduct steam. This will lead to the fact that wood will be rotated, and in the premises the humidity will be above the norm.

Another important point: Operating a wooden house with bricks only after the main shrinkage of the cut will be held. And this is at least 1.5-2 years. In this sense, it is easier to with old wooden houses: they have passed the main processes.

About other options outdoor finish at home read here.

Pluses and cons of a wooden house covering by brick

The combination is so different in all characteristics of materials - the case is complex and completely ambiguous. From the positive moments you can allocate:

- Reduced fire hazard.

- Reducing heating costs.

- Wood is protected from direct contact with atmospheric precipitation.

In the context, brick facing of the brusade wall looks like this.

Negative moments enough:

- When building houses for a normal microclimate, it is necessary to follow the rule: the vapor permeability of the materials changes from less to the greater from the inside. If you put a log house with brick, the situation is reverse. As a result, the moisture accumulates in the insulation. In winter, she freezes there, turning mineral wool into Truch. In the summer - creates conditions for the development of mold and rot. Only the creation of ventilated cladding can correct the situation.

- The wooden house constantly changes the dimensions, because hard ties with the brick wall can not be done. Facing the house brick and the walls themselves should move independently of each other.

- Brick - heavy material and its mass must be considered when calculating the foundation: the load becomes much higher. Therefore, it is required or a higher concrete brand, or a large width in a tape foundation, or a large thickness in the slab. On the pile or pile-painting foundation, the facing can only be set after the calculations.

Table weighing finishing bricks of different sizes

In general, a nonideal decision. If the house is just planned, think several times. Maybe it is better to build a house from foam blocks (gas-silicate), and then put them with bricks. These materials are much better consistent and complement each other's qualities. Waste the wooden house with brick stands if the house is old, the wood darkened, it is necessary to give him a more attractive look.

Technology cladding walls

First, wood is treated with protective impregnation for outdoor work. Then the label made of planed timber (also impregnated). The dimensions of the bar depend on the required thickness of the heat insulating layer. Usually for the middle strip of Russia, the basalt wool thickness is needed about 50 mm for more northern regions from 100 to 150 mm. But specifically everything is considered depending on the thickness of the wall (from a bar or logs) and the brick chosen for cladding.

The insulation is stacked very tightly, without gaps: the lamp is stuffing, taking into account its width. The distance between the bars should be a pair of centimeters less than the width of the insulation. So the material will be laid with the effort. It will make it tightly to the crate, which minimizes the formation of cold bridges.

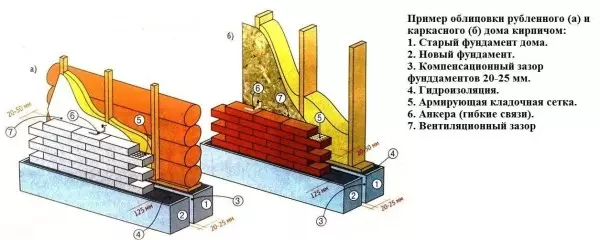

An example of a brick wall lining of a wooden and skew house

On top of the insulation laid windproof membrane. It must necessarily be vapor-permeable, and if the vapor permeability is one-sided, the withdrawal of moisture is necessary from the room. Fasten the membrane with a stapler brackets to the crate. Next, leave the gap for ventilation at least 60 mm and put the wall from the facing brick.

How to make it right

There are several subtleties that need to know. Place the house usually in Polkirpich. Without the support of the wall, it turns out a rod, especially with large areas. So that it stood firmly, it is associated with a wooden wall. There are two ways:

- A nail (100-150 mm) is driven into the wall for half a length, bend up. It is tied to a piece of soft wire with a diameter of 3 mm. Slush length - a little more than a meter. The wire is fixed by the middle for a nail, twisted and undergoes the middle of the brick twisted, then divorces on the masonry on the sides. The nail is descending so that it twisted into the ring.

- Use strips of 25-30 mm wide and about a meter long. The band in the middle is nailing nail (spin self-tapping), as the wire together lead to the middle of the brick, they are bent and bred on the sides.

- Use the mesh for masonry by circumcalling it so that the rods reached up to about the middle of the bricks. So that the rod does not jump out of the solution, it is better to go aside, as in the photo. Such dressings are arranged in each fifth row.

In this way, you can connect the wall at home and brick facing

Single dressings must be located over the entire wall surface. Recommendations There are different - at a distance of about 50 cm one from another or 4 pieces per square meter.

If you are going to put the house with bricks with your own hands, there may be problems with the horizontal and vertical of the masonry. The following technique can help simultaneously control all directions:

- In the corners of the house under the roof and above the basement, long pins are horizontally clogged. They must perform from the wall at the distance, more than the whole thickness of the finish.

- On one corner to the upper pin at a distance corresponding to the outer edge of the masonry, the wire is tied and lowered down, movably fixed on the lower nail.

- It is checked and the vertical is checked, it is strictly fixed.

- Also, at the same distance, a vertical wire is tied at the other end of the wall.

- There is a horizontal cord between the two stretched strings. It will serve as a landmark when laying: it can be moved up as the ranks of the rows. Only every time you need to check the horizontality using a level.

All of the above belongs to the frame houses. They also require a ventilation gap device. The situation is similar: outside the material is much worse than the conductive moisture than those located inside. Only the wire or strip of tin for dressings are fixed in this case to the frame racks.

Reinforced or not

In general, reinforcement makes the wall more durable and reliable. Therefore it is better to rein. But it complicates and slows down the masonry, which leads to the rise in the cost of work (if the masters hired).If you are doing, then the rows with the reinforcement must be approximately every 5th row. As the reinforcement, I put a special mesh with a cell 50-50 mm or two longitudinal rods of reinforcement with a diameter of 6 mm. At the same time, the seam size is in a row with reinforcement, which should not be the same.

The house facing the brick "live" is filmed on the video, the technique of laying "under the rod". The seams are obtained beautiful, but water is pushing, absorbed later by brick. Therefore, it is impossible to leave in this form of the seams. They must be filled with a solution and squeeze in one plane with the surface of the brick. Then the absorption of water during the weather will significantly decrease, and the life of the "life" of the brick lining of the walls will increase. The process of the masonry is demonstrated correctly: the solution is stacked carefully, the drops that fall on the surface immediately rubbing.

House facing brick from aerated concrete, foam concrete and gas-silicate

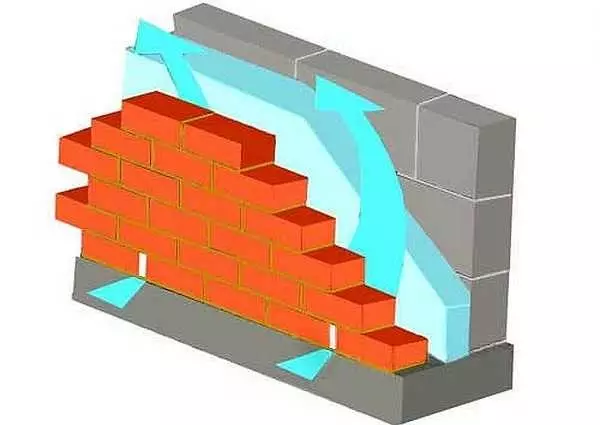

Parry permeability of cellular concrete is also higher than that of a brick. That is, the situation is exactly the same: inside the room there is a material, better outcoming pairs. Therefore, to ensure a normal microclimate in a room and a long service life, a ventilation gap is required between the brick masonry and the wall and foam blocks.

If you put a house made from aerated concrete (foam concrete, gas) brick without a gap, its service life will decrease by about 60%: condensate will accumulate on the border of two materials. At low temperatures, the frozen moisture will destroy the bubbles shell, gradually destroying all the material and significantly worsening its characteristics.

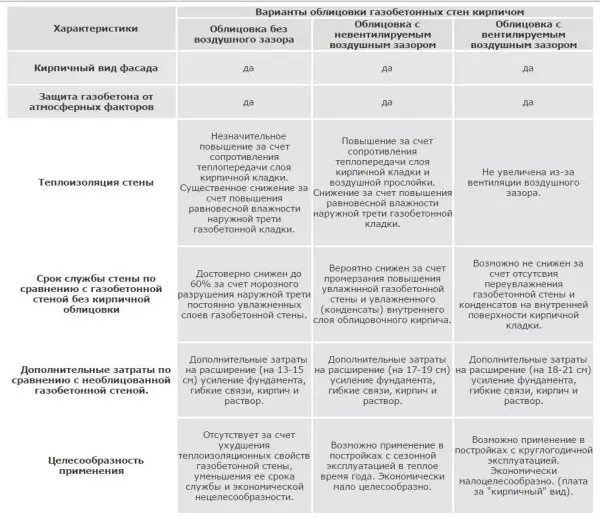

Variants of a device of facing a decontamination house brick and their characteristics

Additional insulation are used very rarely, if they are still needed, all the rules are the same as during the facing of a wooden house: basalt wool protected by wind insulation.

About the features of the finish of the house from aerated concrete (gas-silicate) read here.

The magnitude of the ventilation gap is from 60 to 150 mm. The number of connections between the two walls: at least 3 pcs per square meter of masonry, their cross section is not less than 5 mm2 per 1 m2. To connect, you can use screw or stainless nails with a length of at least 120 mm. They are clogged not perpendicular to the wall, but at an angle of at least 45 °. You can use punching bands with perforations, which on one side are nailed by building blocks, and the second end is started in a brickwork where the angle is bent. Note: Communication should not be laid in the laying seams of the main wall. Just nailed to the front surface of the blocks.

The best facing of walls from aerated concrete and foam concrete - a brick with a ventilation gap

Slag or slag house

Facing with brick in the case of buildings with the use of slag is used more often when cracks are sprawled along the walls. It happens mostly when the slag has exhausted its resource and began to crumble. On average, its service life is 50 years old, it is reduced if the moisture of the walls was elevated.The brick lining of the house from the slag block (slapped) will only fail the inevitable: will slow down the destruction, but will not stop it. The duration of the delay depends on the state of the material and from the measures taken. On average, it is 8-15 years old. Without consulting a specialist, it is unlikely possible: too much error price.

In most cases, it is recommended to build a frame around the house, which to transfer part of the load of overlapping and roofing, carry out waterproofing. One of which is the outer protection of the walls of atmospheric precipitation with a brick facing. Brick is chosen with the smallest water absorption. For greater protection, the masonry can be soaked with hydrophobic composition (only not creating a steamproof film). It will not be superfluous and penetrating hydrophobic impregnation of the main wall. To do this, you can use the impregnation of the type "Penetron" and analogues. They will at the same time strengthen the material and will decrease the water saturation.

About the practice of cladding old buildings brick watch video.

About choosing suppliers and prices

Prices for the same materials are very different depending on the region. In order to correctly appreciate the situation, you need to conduct your own market research: call or visit the largest suppliers, view offers in the region in the network. During the call, you need to mined technical data, find out the prices. Then compare the characteristics of the brick, mapping prices.

What can be advised: do not buy too cheap materials. If the difference from the average market price is 15-20%, most likely, it is last year's remnants not the most successful party. Otherwise, look at the ratio of the price and the stated characteristics.

Average prices in Moscow are as follows:

- Silicate facing brick - 11-21 rubles / pc;

- Ceramic facing - 18-35 rubles / pcs (full-time 45-65 rubles / pcs);

- hyperpressive debt - 25-31 rubles / pc;

- Clinker - 27-40 rubles / pc.

By choosing some possible suppliers, look at their goods personally. Smooth faces, uniform painting, no cracks and any defects - that's what you should see.

About the size of the party. It is advisable to buy the entire volume of material for cladding immediately. It will help to save about 10-15%. Some suppliers of large batches are offered to bring dump trucks directly from the factory. It is cheaper, and additional overload is excluded, which means there is less fight.

The advantages of wholesale purchases also in the fact that the party is likely to be one that guarantees uniformity of the color. In any case, the house facing brick is conducted from several packages at the same time. So even a little different shades will not create color spots.

Article on the topic: How to make a dryer for linen on a balcony with your own hands