Soundproofing is an important stage of repair, especially if it comes to a panel house. It is very important to choose the right soundproof material. When choosing, the character of the draft floor should be taken into account. In the panel house it can be either concrete or wooden.

Soundproofing today can be equipped with two different ways. At the same time, installation work can be performed with their own hands, not attracting highly qualified specialists. The first method is budget, and involves the use of elastic flooring. The latter include:

- Thick linoleum on a special substrate;

- carpet;

- foamed polyurethane;

- laminated board laid on a special substrate;

- Coverage from traffic jam.

If we consider the price policy of the question, then the most expensive option will be sound insulation with the help of foamed polyurethane, which is also called polyurethane foam. It cannot be used as a decorative flooring. Therefore, it will be necessary to cover with linoleum, laminate or any other decorative coating.

The remaining covers that were listed above are initially decorative. In addition, their laying does not require careful preparation of a rough base. If concrete floors are relatively smooth and do not have defects, then you can do without the arrangement of the screed. If there are large defects, they will have to be selected by cement-sandy solution.

There will be some money and time to such work. After that, it is advisable to pour a concrete base with a thin layer of self-leveling mixture. After drying, it forms a smooth surface.

All small defects can be leveled by a special substrate. There are substrates of different thickness. The more defects on the ground, the thicker the substrate should be taken. All preparatory work can be performed with your own hands. It does not have to spend a lot of money. All material used (cement, sand, water, self-leveling mixture, substrate) has a low pricing policy. After drying, the solution you need to put a decorative floor covering.

Article on the topic: Gypsum stone and its manufacture with your own hands

The main advantage that such sound insulation has a relatively low pricing policy. In addition, all the work can be easily done with their own hands. On this, perhaps, the list of advantages ends. But there are much more flaws.

After the flooring, the sound insulation indicators will not significantly change. Will be a bit quieter. But noise insulation suggests something more. The problem of sound insulation is to maximize yourself from noise that produce neighbors. It is worth noting the fact that with such a floor arrangement, it will not be durable.

Floating floors

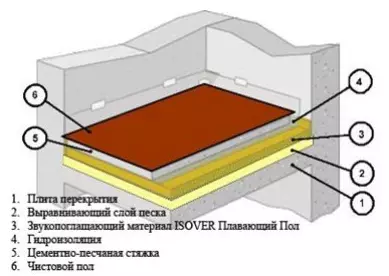

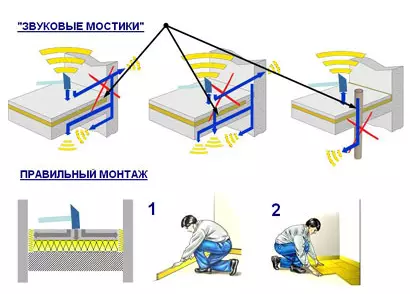

Most extraneous sounds are transmitted in the form of vibrations from the walls to the base. If, say, it will be possible to somehow separate the walls from the floor, it will be possible to significantly increase the soundproofing characteristics of the room. That is what was taken as a basis in the development of floating gender laying technology.

The draft floor is filled with a screed, which does not reach the walls. A material that levels all vibrations is labeled between the walls and the screed. Installation work uncomplicated. They can be performed with their own hands. True, this method of sound insulation is quite expensive.

Consider how to equip the floating floor. Start mounting work from the preparatory stage. It is necessary to align the draft base. If there are defects, you need to get rid of them. In this case, cracks, gaps or chips are shaky, and the bugs are appropriate to cut. You can, of course, align the base, focusing on the highest point of the floor.

But in this case, you will need to put a fairly thick layer of the screed. The height of the room will eventually decrease significantly. Yes, and the difference between the height of the floor in different rooms will be essential. Therefore, you have to break your head over how to make a transition from one room to another.

Close-up cracks, chips or gaps can be cement-sandy solution, sealant or self-leveling mixtures. The easiest way will work with a sealant. It is sold in the form of a ready-to-use composition. A cement-sandy solution or self-leveling mixture will have to be prepared.

Article on the topic: Technology facing wall bricks - how to prevent errors?

Next, you need to put the thermal insulation material. It is better to stop your choice on those materials that are resistant to moisture. Otherwise, you will have to be engaged in the floorproofing of the floor. It is advisable to put the reinforcing grid on the thermal insulation material, which will make the design more durable.

Then, you need to put the screed. It should not fit to the walls. Therefore, it is pre-needed along the walls to lay the material that levels the vibration. If he is unstable to moisture, it needs to be hydroizing.

Next, you need to put the screed. If the room in which the sound insulation is large, then with the arrangement of the screed should be used lighthouses. If work is carried out with your own hands, it is advisable when the screed is used to use self-leveling mixtures. They differ plasticity, which facilitates installation work.

The last stage of work involves the installation of a decorative floor covering, which, like the screed, should not touch the walls. The gaps between the decorative flooring and walls formed during the laying should be sealing with a sealant leveled vibration.

After drying, the sealant needs to install the plinth. At the same time, it should be fixed this decorative element only to one of the bases: either to the floor or to the wall. Soundproofing is ready.

Such noise insulation has a number of advantages to which the long operational period relates, protection against penetration of foreign noise, the absence of mechanical fasteners, uniform distribution of the load on the surface.

In addition, after the floating gear arrangement, the characteristics of thermal insulation are increased, which is important in the panel house. All installation work can be performed with your own hands. During operation, there is no need for repair or prevention.

As for the shortcomings, such sound insulation is expensive and requires a clear compliance with the technology of installation work.

Isolate wooden floors

Sometimes wooden floors can be found in the panel house. Soundproofing of a wooden base, compared to concrete, is quite costly. This is due to the fact that the floor consists of boards, the joints between which are notometric. Accordingly, all sounds penetrate through these joints. Therefore, they will have to close the vibration-insulating sealant.

Article on the topic: Wallpaper lemon color in the interior of different premises

Then, the arrangement of the sound pillow should be done. Lags are mounted on the floorboards. There is a dry insulating material between lags. It can be clay or sand. At the same time, dry material is not on the entire height of the lag.

After laying a clean base, half of the space should remain empty. Since the air is a bad conductor, it will also act as a noise insulating material. Then, you need to put the finishing floor. Noise insulation is ready.

Noise insulation is a fairly important aspect of repair. At the same time, it is not necessary to believe that it will achieve absolute sound insulation. There are currently no technology that allows you to fully protect your apartment from outside noise. Sound insulation is quite costly pleasure. The use of inexpensive materials and technologies will not give the desired result.

In addition, you need to use only a certified product that is recommended for use in a residential building. If all work is performed with your own hands, then you need to comply with the technology of installation work. This is especially true for the arrangement of a floating screed.