Recently, laminate is gaining increasing popularity. Not the last role plays simplicity of installation of this floor covering.

It should be remembered that it is necessary to insulate the floor under the laminate, otherwise it is possible to walk on it only in slippers.

Laminate is very durable and wear-resistant coating, but before it laying the base is desirable to insist.

The list of insulation works depends on two factors:

- On which floor - wooden or concrete - laminate will be laid;

- What type of insulation is selected.

Since each owner knows what sex he has in the house, let's talk about choosing materials for insulation.

Than you can warm the floor

Substrate

One of the most common types of insulation. As a substrate uses Faneur, Feds, foamed polyethylene, isol, wood-chip coating. The substrate thickness depends on the unevenness of the floor, the height of the ceilings and the selected material. The foamed polyethylene will be cheaper, however, in one layer it can only be put on an absolutely smooth floor. If you need to smooth out irregularities, you will have to fold the material several times.

Bung

Polystyrene foam will help hide the irregularities of the base when laying a laminate.

Very expensive, but it is an environmentally friendly material. Such a substrate will last long, providing not only heat, but also sound insulation, air circulation. In addition, it takes a minimum of space.

Ceramzit

It is used mainly for the insulation of wooden floors. It is desirable that the layer of clay is at least 10 cm, otherwise it will not be possible to achieve good thermal insulation.

Mineral wool

Inexpensive, durable insulation. Minvata must be closed on one side by foil or metallized film. Outdoor material can be used only for thermal insulation of non-residential premises.

Styrofoam

Pretty cheap, light and very practical material. It may be small and coarse-grained. Basically consists of air, which holds heat. It has excellent sound insulation characteristics.

Foil

Foil is often used for the substrate, since this material is durable and is cheap.

Produced in rolls and plates. With proper operation will last long. Stop material is necessary to reflect the surface down, then the heat in the room will be able to save.

Polyurene Foolder

May be sprayed and filled. Perfectly absorbs moisture and retains heat, durable, does not harm health. It requires special equipment to use it, so the material laying is better to entrust specialists.

Article on the topic: Warm floor under laminate on the wooden floor with their own hands

Warm floor

A special type of float insulation under laminate. It can be electric or water. In the first case, cables are located under the laminate, in the second - water pipes. When the system is turned on, cables or water in the pipes are heated, giving heat outdoor coating.

Preparatory stage

Screed will help align the base under the laminate.

Paul insulation should begin to eliminate surface deficiencies. Concrete floor needs to be aligned: pour existing depressions or pits, throw buggers, sharpen chips and cracks. If the floor is wooden, the boards will have to be dismantled. It is possible to equip waterproofing so that the moisture does not get into the laid insulation.

It is advisable to take care that in the process of work at hand there were all the necessary tools:

- electrolovik;

- screwdriver;

- Drill with various nozzles;

- a hammer;

- Dowels, selflessness;

- level or rule;

- roulette;

- marker or pencil;

- Building stapler and knife.

Depending on the type of insulation selected, the list of tools can expand somewhat. For example, a shovel will be required to lay a clamping, and when using filling materials - a container for cooking them. Optional to buy the required tools. You can lend something from friends or rent - such services are now provided by many construction companies.

Wood insulation of wooden floors

Wood insulation can be performed using minvati.

Most often used the heat insulation method for lags. It should be remembered that such an option of insulation will steal up to 10 cm of the room height, so you need to carefully consider the selection of thermal insulation material and its thickness. Stages of work on laying insulation are as follows.

- On the draft floor they put a frame of wooden bars (lag). If the lags have already been installed, but they caught or crackled from time to time, they can either be replaced or cut to one level. The distance between bars - 50-60 cm.

- The gaps between the lags are filled with insulation. It may be clay, foam, mineral wool. If the material is used in the plates, they must be fixed. Minvata in rolls does not need this.

- On top of the insulation laid a vapor insulation layer. You can use a conventional polyethylene film. To seal joints, it is recommended to consolidate them with scotch.

- In order for the floor to be as smooth, you can lay the OSB slabs or chipboard.

- On the plates or immediately on the layer of vapor barrier, wooden floors are stacked, and already on them - laminate.

Thermal insulation of concrete floor

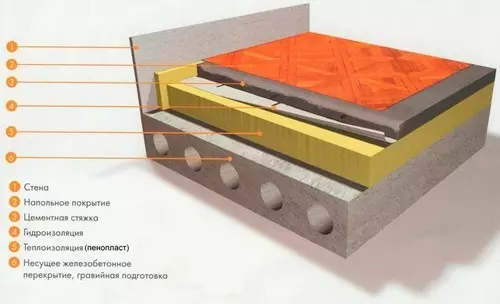

The scheme of thermal insulation of concrete floor by foam.

On lags you can warm and concrete floor under the laminate, but only if its surface is not too damaged. Otherwise, you will have to align it first and only then put a wooden frame, which will still reduce the height of the room. In addition, there are less labor-intensive methods of thermal insulation of concrete floors.

Article on the topic: crafts from the mounting foam with their own hands

First of all, it is necessary to identify how many centimeters of height can be sacrificed to put the insulation. Well, if the ceilings are high and allow to steal up to 10 cm. Even better if the concrete tie can be fed again by adding clamzite to it. Laying under the tie of thick plates of mineral wool or color fine-grained polyfoam is also possible. A good option - the use of double baking. First, the layer of wooden boards is placed on top of them - the substrate, and from above - laminate.

If the insulation is able to select no more than 3 cm, it is recommended to use self-leveling mixtures. It is necessary to knead the solution in accordance with the instructions on the package, pour it out on the floor and evenly distribute the spatula. After a few hours, the mixture hardens, it will be possible to lay a substrate, and then laminate. If the concrete base does not contain significant defects, the insulation layer may not exceed 1 cm. Otherwise, it is necessary to increase it so that all the bumps hide the mixture.

On an even concrete coating, such materials can be laid:

- polyurethane foam;

- Hypus fiber sheets;

- foamed polyurethane;

- Isolon.

The thickness of the insulation will be no more than 2 cm, but will allow to ensure good heat insulation.

If there is no possibility or desire to lose the centimeters of the room height, you can purchase a thin heat insulating membrane. The material has two modifications: with or without foil. The membrane is glued directly to the floor using special glue.

We draw a warm floor

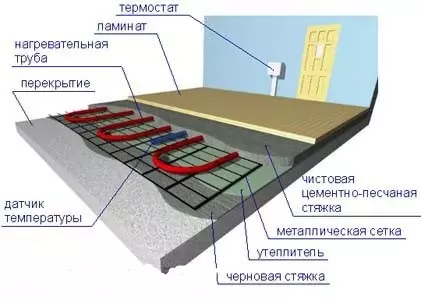

Water floor diagram.

This type of insulation is the most effective because it ensures the uniform distribution of heat around the room. The advantages of such systems can be rapidly evaluated in winter, because the batteries are not heated. The process of arrangement depends on what kind of type of heat is selected.

Water Pol

Much more cheaper by electric costs. For its arrangement, a solid metal-plastic tube will be required, which is placed by snake throughout the floor. Ideally, the pipe should be put in the screed. The distance between the pipe and the outer surface of the laminate should be not more than 3 cm, otherwise the heating effect will not be felt. If there is no possibility to put pipes into the screed, aluminum plates for the distribution of heat are placed on the aligned concrete floor, and they are put on the pipes. The entire design is overlapped with chipboard sheets, drywall or plywood laid in two layers of peaks, and fasten them with self-draws.

Article on the topic: Installation of the skirting at the table top for the kitchen

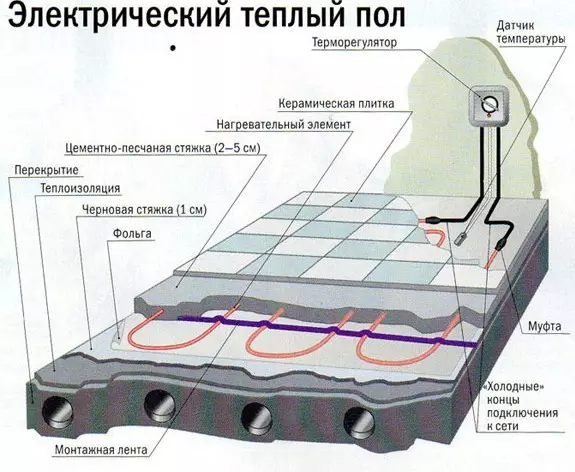

Electric floor

Very expensive pleasure, as it consumes a lot of electricity. But this gender takes less space than water, and its temperature can be adjusted more precisely. Depending on the materials used, it is divided into 3 types:

Electric heating floor diagram.

- Infrared floor. Mounted easily and quickly, as you can insulate the floor using a special film. A heat transfer substrate is placed on the purified surface. The film is cut into the bands of the required length and placed rods down. Next connect the wiring and set the thermostat. All connections must be extended.

- Rod mats. Stay on a flat surface. In places, the turns of the mats are cut so as not to damage the cable. In the end, it is necessary to return to the place from which the laying of the material began, and connect the ends of the cable to the thermostat. Now you need to check the resistance and integrity of the compounds. If everything is in order, you can lay a laminate.

- Cable floor. Least effective type of warm floor. Cables must be put into the sand-cement screed, cover the substrate, and then mount the laminate. That is, they will have to warm all the inner layers first, to then give the heat of the floor. This will take a certain amount of time and electricity. You can start using the system only after 28 days - after full frosting of the screed.

Several important tips

The warm floor should not be laid under the furniture and household appliances, otherwise there will be strong overheating in these places, which will lead to increased electricity consumption, will spoil the laminate, heating elements and surfaces of objects.

Along all the walls of the room, it is necessary to put the thermal insulation material with a thickness of at least 1 cm so that the space for the expansion of the laminate remains, and there are no cracks and other defects in the floor.

Before starting laying the substrate and flooring, it is necessary to include an assembled system for two days to check its performance and heat the surface. Laminate during this period should be indoors. Each day, increase the temperature of 5 ° C until it reaches 15 ° C.

The maximum temperature on the surface of the laminate during the operation of the warm floor is 27-28 ° C.

When choosing a insulation, it is necessary to take into account not only the height of the ceilings, but also the level of humidity in the room. Some insulation cannot be used in a wet environment, it will be necessary to equip waterproofing for others. Properly selected insulation and its competent installation will provide a long life of laminate.