The quality of sawn timber depends on the properties of round timber, more precisely, from the presence of vices.

From the signs of round timber, that is, the quality of sawn timber depends on the presence of defects.

In the regulatory documentation, the defects are more than 80, but the types of materials are determined by only 10 types of flaws (signs).

Therefore, before dealing with the sorting of sawn timber, you should understand what signs of round forest affect this process.

On varieties of round forest and sawn timber

Initially rounded, depending on the tree of wood, divide into two groups: coniferous and deciduous. The next step is the division of thickness. For both groups of timber in thickness, three types are provided: small, medium and large.

By type of processing, rounding is divided into four groups. It can be:

- Use in a round.

- Transform into wood ground or recycle on cellulose.

- Turn into a veneer by imagination or planing.

- Turn into lumber.

Lumber is divided into four varieties:

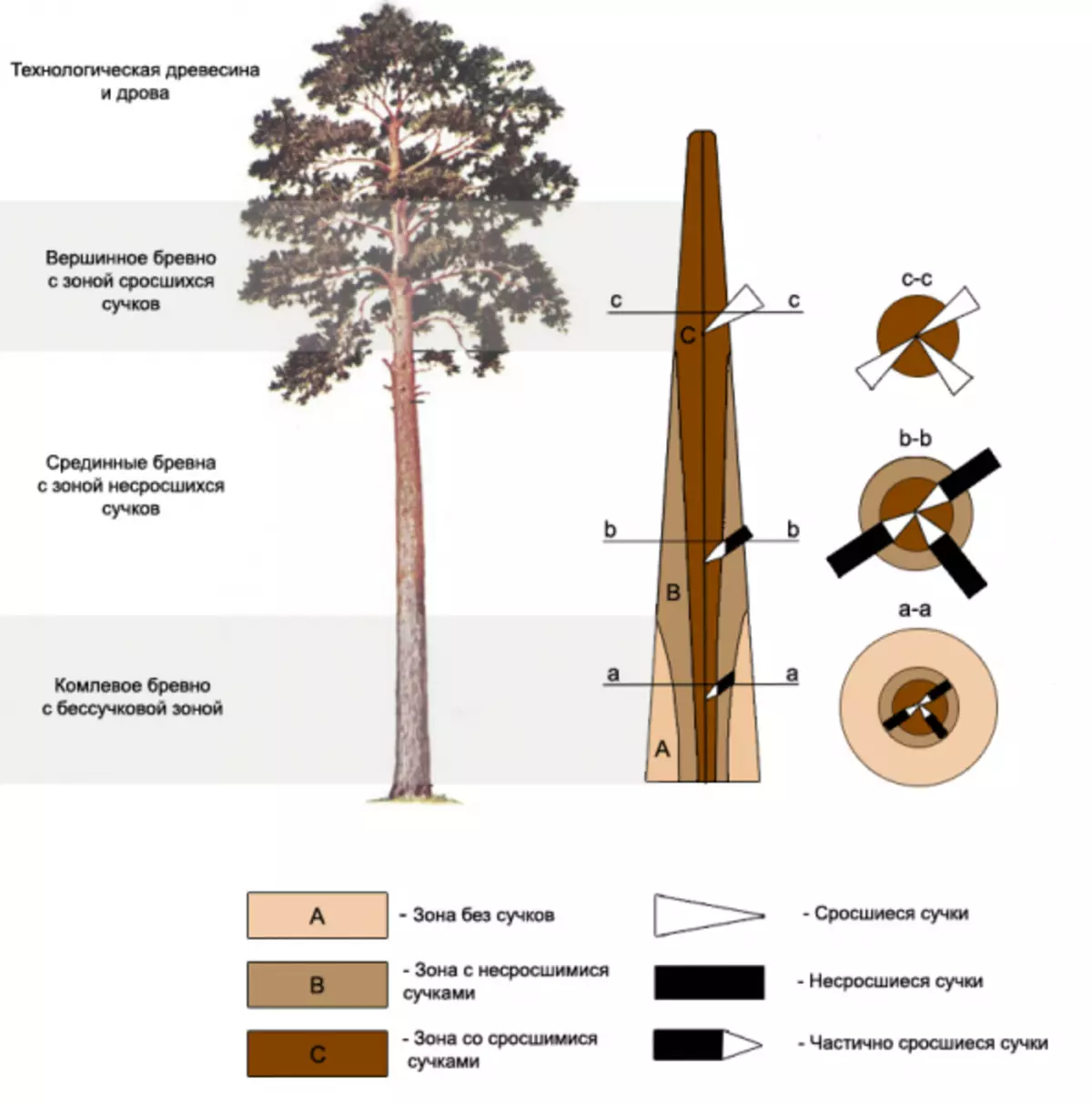

Image 1. Scheme of squals of whips.

- 1 grade is obtained from a compence part of a log, in which there are practically no bitch;

- 2 grads are obtained from a comlek and median part having a small amount of bitch;

- 3 and 4 grads can be obtained from any part of the log;

- The highest, selected variety is highlighted in a separate category.

The variety in the process of sorting sawn timber is determined by:

- for the board - for the worst side or edge;

- For a bar or bar - for the worst side.

From which part of the spinal whip which lumber variety can be obtained, understandable in the image 1.

The main signs of fortification are the following:

- knots;

- Mushroom painting and rot;

- Chemical color;

- traces left by insects;

- cracking and deformation;

- consequences of the impairment of the shape of the trunk;

- flaws of wood structure;

- wounds;

- Natural (normal) wood deposits;

- Processing defects and transport damage.

Article on the topic: Designation of sockets and switches on construction drawings and schemes

In the process of sorting lumber as a result, each variety must comply with specific requirements for the absence of flaws. We indicate only the requirements for bitch and cracks.

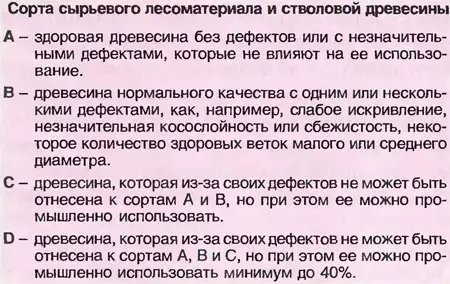

Table of grades of raw material and stem wood.

Selective grade. No vices, except for bitch, are not allowed. Dumps can be no more than 2 per 1 m length. Parts of the bitch are allowed on the ribs of the board, the size of which does not exceed 20% of its diameter.

- 1 grade. There should be no bitch, the diameter of which exceeds 10 mm, bitch that can fall apart at any time, and the depressions remaining from the already dropped bitch. The total length of cracks (non-crosswise) should not exceed a quarter of the material length.

- 2 grade. There should be no drop-down bitch and healthy bitch, the diameter of which exceeds 20 mm. The total length of cracks (not through) should not exceed the third of the material length.

- 3 grades. Almost all vices are allowed.

- 4 grades. Vices are defined not for a particular product, but by 1 m3 of the material.

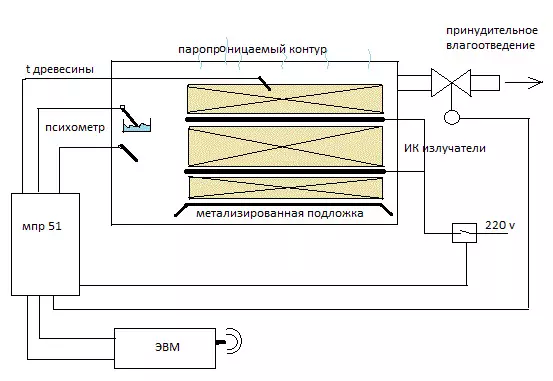

Automation of the technological process of sawing

Before considering the sorting process, it is advisable to establish its place in the automated control system (ACS) chain of wood processing in the enterprise, that is, log movements from entering the enterprise to finished products. This is what this sequence looks like.

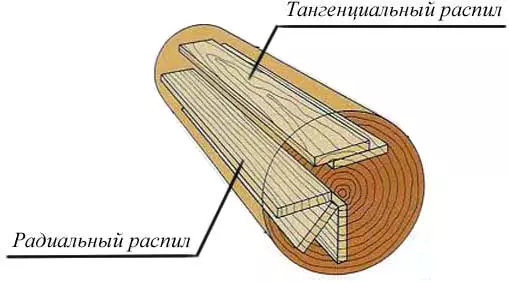

Tree trunk diagram.

- The incoming material (logs) register. This can be done manually or using an automatic acceptance line.

- Fantasy and sawing, for example, on the boards.

- Crude sorting boards using a local line.

- Feeding boards to special machines that form a stack further into the drying shop.

- Drying boards and their movement in stacks within the drying shop.

- Feeding boards on a dry sort line.

Next, the formation of packages is carried out in accordance with the results of the sorting.

It turns out that the distribution of lumber in varieties begins after sawing the log, that is, from the same rounder, you can get a different material in quality, which makes the dry sort line. In the technological chain, the sort line is located after drying.

Article on the topic: Liquid wallpaper. Advantage and disadvantages of liquid wallpaper

Such a place of the local subsystem of sawmasonry sorting in the ACS technological chain allows you to identify the bitch drops drop down after drying and negative the other flaws.

Automation of the process of sorting sawn timber

In the process of manufacturing the board, the sorting is performed twice: to drying and after it.

When preparing for drying, partial trimming of boards to eliminate vices at their ends are performed. The boards are sorted by tree rocks and in the size of cross-sections. After drying, they are sorted in quality and in the last stage is carried out in length.

The division in the size of the cross sections is necessary for the formation of homogeneous drying packets, which are selected by the corresponding mode and drying duration. The thickness and width are measured anywhere on the board, but not closer to 150 mm from its ends. For low-grade boards, packages can only be formed taking into account their thickness.

Scheme of sawn timber.

At this stage, the line operator, having received the size data, sends the product to the appropriate drive, in which the specified number is created, after which the drive is opened and the material on the conveyor is directed to the drying workshop. Drying bags are formed in the workshop.

The division of lumber in quality can be carried out by the controller when the boards on the tramer tables in the sawing workshop. However, on the tables more than 7-8 boards per minute the controller will not be able to sort.

The main division is performed on transport conveyors. Control is carried out by several operating controllers. They are located sequentially along the conveyor and manually change the direction of movement of the boards to the appropriate drive.

This method is not only not only from automatic, but also it is impossible to call it.

About the automation of the process can be said if the board unfolds during the conveyor movement so that the operator has the opportunity to inspect the board from all sides and, deciding to which class to be attributed to, send it to the appropriate drive. To do this, on the conveyor there are a chiber, which he controls.

Article on the topic: We carry out the balcony finish correctly: Basic Rules

The operator may at its discretion change the types of boards. Sometimes it happens that, taking into account the entire length, the board corresponds to the 3rd class. But there is a plot of sufficient length in which the number of defects meets the requirements of a higher class.

It is clear that this method of division in varieties is inffective and is suitable only for production with a small volume of products. For large sawmill enterprises, it is economically advantageous to create automatic lines.