With the development of technologies, pressed products appeared on a wooden basis, and then completely different finishing materials that are manufactured without the use of wood or with its imitation in the figure.

Today, the use of wooden floors is relatively expensive. The cost of such a coating exceeds many alternative options, moreover, during installation, the wooden floor grinding and the applying varnish is required.

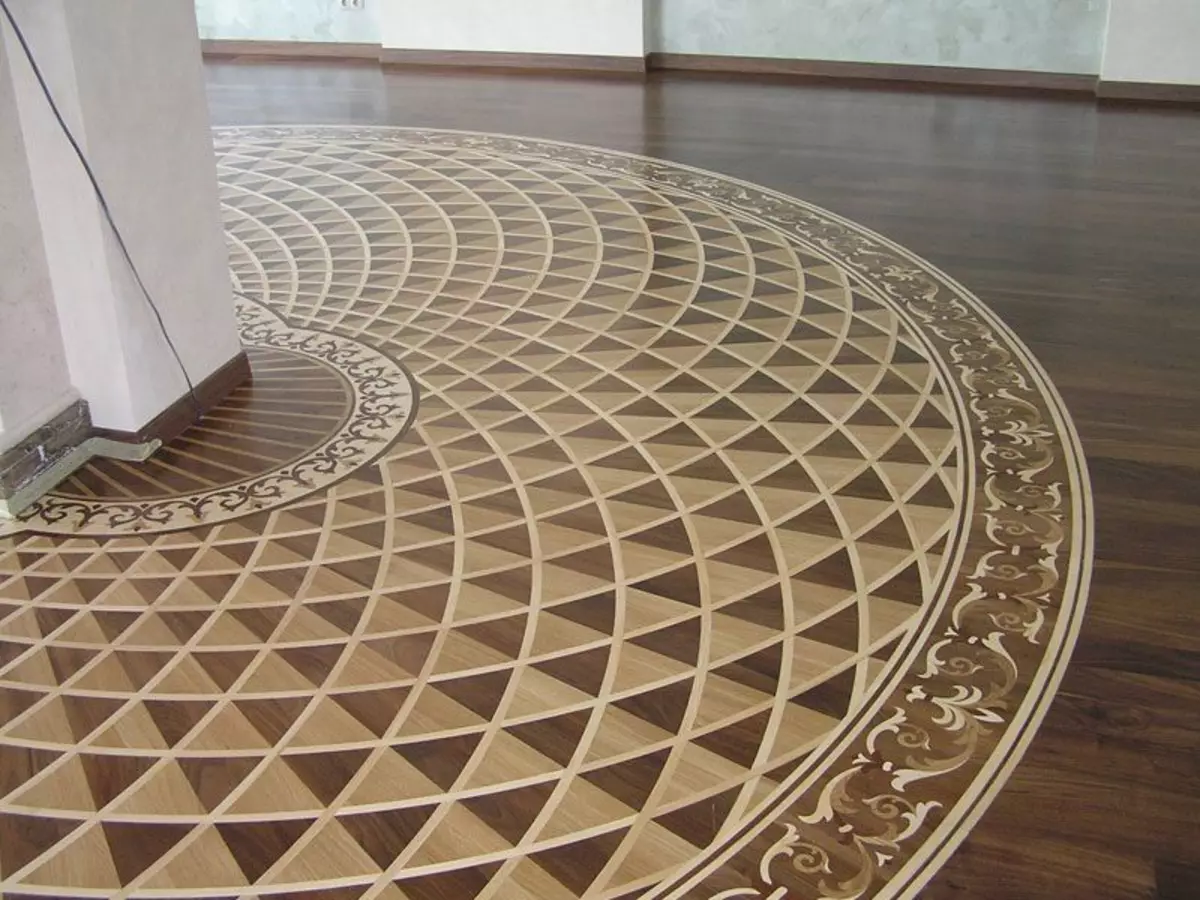

The beauty and environmental friendliness of this base allow you to remove the price component to the background and seriously think about the flooring device from natural material.

Varieties of wooden floors

Parquet, like a board coating can be grinding

The main types of wooden floors include two types.

- Boating floors.

- parquet.

The boarded floors are harvested from edged plates of rectangular sections laid on pre-installed lags. For high-quality assembly, tank boards are made. They have in a narrow part of the longitudinal grooves for the assembly in the castle.

Boarding flooring collected from headboards

Parquet is arranged from set planks or shields that are installed on an even pre-prepared draft base.

In some cases, it is necessary to grind the wooden floor after the assembly. When coating from edged boards, this procedure is mandatory.

It can be produced for old wooden coatings in order to give them a new and beautiful look.

It is worth noting that the grinding floor must be covered with a protective lacquer layer.

Grinding wooden floors

The work associated with making a smooth and smooth surface of the coating collected from the ordinary floors consists of several stages. After completing each of them, you can count on obtaining the expected result, which is a beautiful glossy floor.Article on the topic: How to make a tree drawing on the wall

Preparatory stage

Before grinding the floor in one room, protect the second from dust

When repairing the old wooden floor, first of all, its complete clearing is performed. The furniture is cleaned, plinths are removed and the floor is inspected for the presence of metal elements, such as nails, brackets and self-tapping screws. All this must be removed from the floor surface.

Then the main elements of the floor itself are examined. If there are damaged rotten boards or some parquet floor planks are rolled and unimpressed, such elements are replaced with new ones.

Accordingly, before passing away the new wooden floor, the actions described above will not have to perform, but individual protection measures must be performed.

Polishing is a sufficiently dusty process, so protection will be required both the manufacturer of work and neighboring premises. Such measures of protection and precautions include the following actions:

- You must open the windows so that fresh air flows into the room.

- The output from the room is better to close tightly. Also does not hurt the wet gauze over the passage to block the spread of dust into other rooms.

- Work in the respirator is a prerequisite when performing such works. Dust is so small, which can penetrate the respiratory tract and cause unwanted health effects. About how to polish the floor with your own hands, look in this video:

An important part of the preparatory stap is the selection of the necessary tool for polishing the floor and consumables.

Selection of tools

Drum type machine

The grinding of a wooden floor with their own hands implies the use of several primary means for work. The main tools with which such works are performed:

- Drum type machine. By its design, it can be compared with a lawn mower. This equipment is professional and worth a lot of money, acquire it for one-time use is inappropriate, but it is quite acceptable to take it for rent for work. The machine allows you to qualitatively perform polishing coating. Most of the dust is discharged into a special bag.

- Eccentric grinders. This is a light manual equipment, which also has in its design the dust removal system with assembly in a special bag. The rotation of the grinding circle occurs on an eccentric circle, which allows you to spit the floor with high quality.

Corner grinding machine

- Ribbon grinding machine. This sandmashinka is a device with an abrasive emery ribbon, which in the course of the straight movement processes a wooden surface. The design is equipped with a dust collector.

- Corner grinding machine. Also this manual machine is called a grinder. It does not have a dust collector, therefore, of all listed devices, the air is most of all when the wooden floor is processed.

It is not possible to get to all parts of the floor with auxiliary equipment. This is especially true of the corners and sections along the walls. For such places, hand brushes and sandpaper are used.

If for any reason to polish your own floor independently does not work, you can always contact a specialized organization that will professionally solve this issue.

Grinding wooden floor

Chernovaya processing is made by the coarse abrasive

Wood coating is grouped into several stages. With each new stage, a more gentle processing mode is selected.

- Initially, rough processing is performed. For this, the coarse abrasive material with large grains is selected. Removed the largest layer. Outdoor parquet or board coating must be ground overlap. That is, each passage along a wooden surface should go a little on the already processed part of the floor.

- At the average stage of work, abrasive material is selected with less large grains. Smoothing processing is performed. All coarse roughness are removed.

Finishing polishes polished surface

- Finishing treatment is performed by the smallest abrasive material. The so-called polishing of the floor is produced in two stages to make the coating perfectly smooth surface. If there are gaps in the floor, then they must be sharpened before the last stage of the floor grinding. After applying the replacement, it needs to provide time for drying and only after that it starts to finish the finishing of the outdoor coating. Detailed description of grinding and used tools See this video:

Depending on the initial quality of the floor, the number of processing steps can be reduced or increased.

Protective coating device

After polishing, apply at least 3 layers of varnish

To protect the polished floors from moisture and mechanical damage, it is coated with a special protective material, which can be used by varnish.

A acrylic-based varnishes can be used, as well as polyurethane, epoxy, alkyd and oil representatives.

The amount of layers applied is limited only in the minimum side. They should be at least three, but in the big face you can apply, and five, and seven, and more layers. For details on grinding and varnishing floor, see this video:

The base of the varnish is chosen on the basis of the placement of the room. Different basics give the lacquer distinctive features for which you can choose the desired coating for a certain room.

Wooden floors, polished and covered with a protective layer of varnish, will be an excellent solution for any apartment or country house. With such a reason, the ultra-modern design moves and classical options are well combined. With such floors, the interior will be cozy and attractive.

Article on the topic: Preparation of the opening before mounting windows