The loops for metal doors from aluminum should not only withstand heavy loads, but also serve a long time. Much attention is paid to the method of their installation on the door.

Different types of profile

Loops for aluminum flaps

With the spread of technology, some familiar things change. Doors, for example, are increasingly made of plastic and aluminum. These are modern profile designs, elegant, lungs. But they have a different level of strength. Aluminum solutions are increasingly used for entrance groups of stores, public buildings, many establish them on the verandas of houses. Here are not standard hinges for metal doors, but special systems whose task is to ensure the control of sash that have not quite a standard design.

By the nature of thermal protection, two types of aluminum profile can be distinguished:

- warm;

- cold.

Naturally, these are only conditional names. Warm received such a name for the reason that inside it is a special insert from the polymer material. It serves as a peculiar insulation, so with a decrease in air temperature, the inner part of the profile is not cooled as much as the outer. There is a significant reduction in heat loss. It takes only due to the fact that the thermal conductivity of the metal is high, and the inner surface of the frame still cools.

Cold profile is the simplest technical solution, bent fit metal sheet. He has no internal filler, when frost occurs, all problems associated with the lack of compensation are observed:

- Heat loss,

- sharp cooling of the inner surface of the frame,

- condensate,

- Sometimes - the altitude of ice.

These are the main differences related to the user characteristics of two types of profile and affecting the price of the finished product.

There is another important factor that concerns the types of loops for an aluminum door or window sash. Depending on which profile is used for the manufacture of a constructive, loops are selected:

- overhead

- hidden

- universal

- unilateral.

Article on the topic: How to bring cockroaches from the apartment?

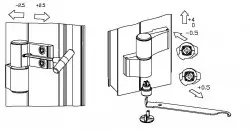

They are fixed in several ways, differ in the material from which the angle of opening, the possibilities of adjustment and other subtleties are made.

Materials used for manufacture

For aluminum structures, hinges for metal doors, systems, the appearance of which are known literally to everyone. However, the same materials are used:

- brass;

- stainless or slaughtering alloys;

- stainless steel;

- Aluminum and alloys based on it.

Each of the materials has its advantages, which forms the applications of certain loops.

Brass.

Brass loops are ideal for creating various coatings. Metal plastic, easily processed, polished, provides good adhesion. Also, brass loops are the most common option in the case of hidden structures, which at certain points in the door movement are visible. Such accessories are very durable, provides long reliable operation, the surfaces are not formed on the surface or color changes. The applied coating is very well held.

Iron-based alloys.

Widely used in adjustable structures. Hidden under overlays or inside the elements allow different defects of the appearance - the surface darkening, erasing, oxidation. The only key requirement for such details is strength and resistance to wear, which can successfully provide iron-based alloys.

Stainless steel.

The most durable material for the manufacture of loops for aluminum structures. They can withstand the huge weight of the canvas, have a modern appearance, the polished surface is very durable, characterized by a pleasant mirror glitter or consciously matted. The oxide film is almost not formed, so the view is the perfect - even color and other characteristics.

The disadvantage is that parts of stainless steel are poorly galvanized. This material is difficult to apply the coating. Another disadvantage is the complexity of processing, so stainless steel loops are the most expensive. If you see the proposal of the market, we can safely say that without linings there are products made of stainless steel only one type: the colors of polished metal or with a matte surface.

Article on the topic: What is airless painting

Aluminum and alloys not by it. Similar hinges are quite rare. Although they belong to the low price group, they have enough deficiencies that limit their use. For example, stainless steel loops can withstand the maximum loads - 150 kg on two hinges is considered a normal indicator.

Similar advantages have a loop from brass - here the recommended indicator of the weight of the door sash is 100 kg per two loops. Aluminum can not boast of such a level. However, the hinges for aluminum constructs from the same material are found at the entrance doors with a small glass area, the total mass in the range of 50-60 kg. Such a solution in the field of hidden loops is especially common.

Methods of fastening

Depending on the profile used, there are several options for connecting the loop with the mounting area of the web. Some of them allow you to maximize the assembly, others provide the possibility of repeated installation, the third applies only for a specific type of profile.

Cold structures. Here is more freedom for engineering solution. The profile is empty, therefore there are no restrictions on the use of anchors, screws or internal fasteners. Distribution received two main ways: mortgage and fast assembly.

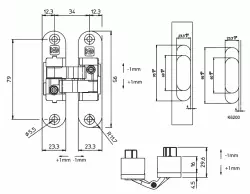

When installing the fallated inside, the part of the profile is placed an element into which screws are screwed. Its design depends mainly on the configuration of space, sizes, profile brands. The ability of the loop carry the weight of the sash depends on the area of the mortgage plate and the thickness of the metal wall. Standard recommendations for this type of fastening sound as follows: 100 kg of door mass, 1.7 mm Thickness of the profile wall, 25 square centimeters of the area of the mortgage plate. For overhead loops of stainless steel, this type of connection is the most common.

Specific anchors are used to speed up the installation. This is an element that is inserted into the hole, when the bolt head is screwed, the inner part expands and reliably presses the loop to the profile. This method of collecting, as well as the previous one, allows multiple installation. You can promote, pull out the anchor, change the loop in case of need.

Article on the topic: How to launch the slopes of the doors with their own hands?

Warm structures. To install products from the profile filled with insulation, embedded plates are used. The difference between the cold profile is that they are placed in advance, in clearly regulated areas. To fix them in the same position, special spacers are applied. Mounting using the spacer anchor is also available.

There is another way - screwing the anchors with a self-timer. Although the installation speed will be the maximum, the key disadvantage is that multiple dismantling-installation is impossible. The thread gradually collapses, the connection becomes fragile. For a warm profile with dense aggregate, a wedge anchor is used - when screwing into the inner part expands and reliably fixes the part.

Special types of accommodation

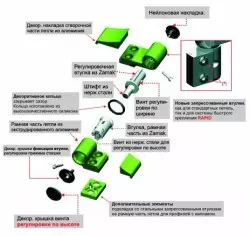

Design hidden

Separately, it is worth noting the hidden loops. They are mounted on the end parts of the aluminum parts. Therefore, it is most often used to fit into a cutout or an overlay on the surface. The mount is carried out using spacer anchors or self-timing connections. Here minimal requirements, mortgages are not used, since the loop itself distributes an effort on the area of its fastening zones.

For aluminum doors, all sorts of loops are used. In order not to reinvent the bike, contact your products suppliers. Some types of fittings can cost inexpensively, but apply only for a specific profile type.

If the goal is to create a completely invisible connection or other non-standard cases, it is worth choosing special accessories for this purpose. Today, there are very many convenient options among technological solutions that can provide any conceivable characteristics, parameters and convenience.

(Your voice will be the first)

Loading…